my drones

yuneec - Edison, Simulink

Yuneec H and Intel Intellisense sensors

| cgoet-manual | mainteanance | pilot-manual |

Overview

Typhoon H Hexacopter

|

Autonomous flight modes allow you to recall pre-programmed tracking shots while focusing on the camera:

Orbit Me: Typhoon H flies a circular path around you, keeping the camera trained on you the whole time. Point of Interest (POI): Select a subject and Typhoon H will orbit that subject autonomously. Journey Mode: Typhoon H will automatically go up and out, as far as 90 m, and capture the perfect aerial selfie. Follow Me / Watch Me: Follow Me ensures Typhoon H moves along with you. Watch Me tells Typhoon H to follow you while always pointing the camera at you wherever you go.

Curve Cable Cam: Easily program an invisible route for Typhoon H to fly along. Typhoon H will fly between pre-set coordinates while independently controlling camera position.

Return Home: Simply switch to Home Mode and Typhoon H will return and land within 8 m of you.

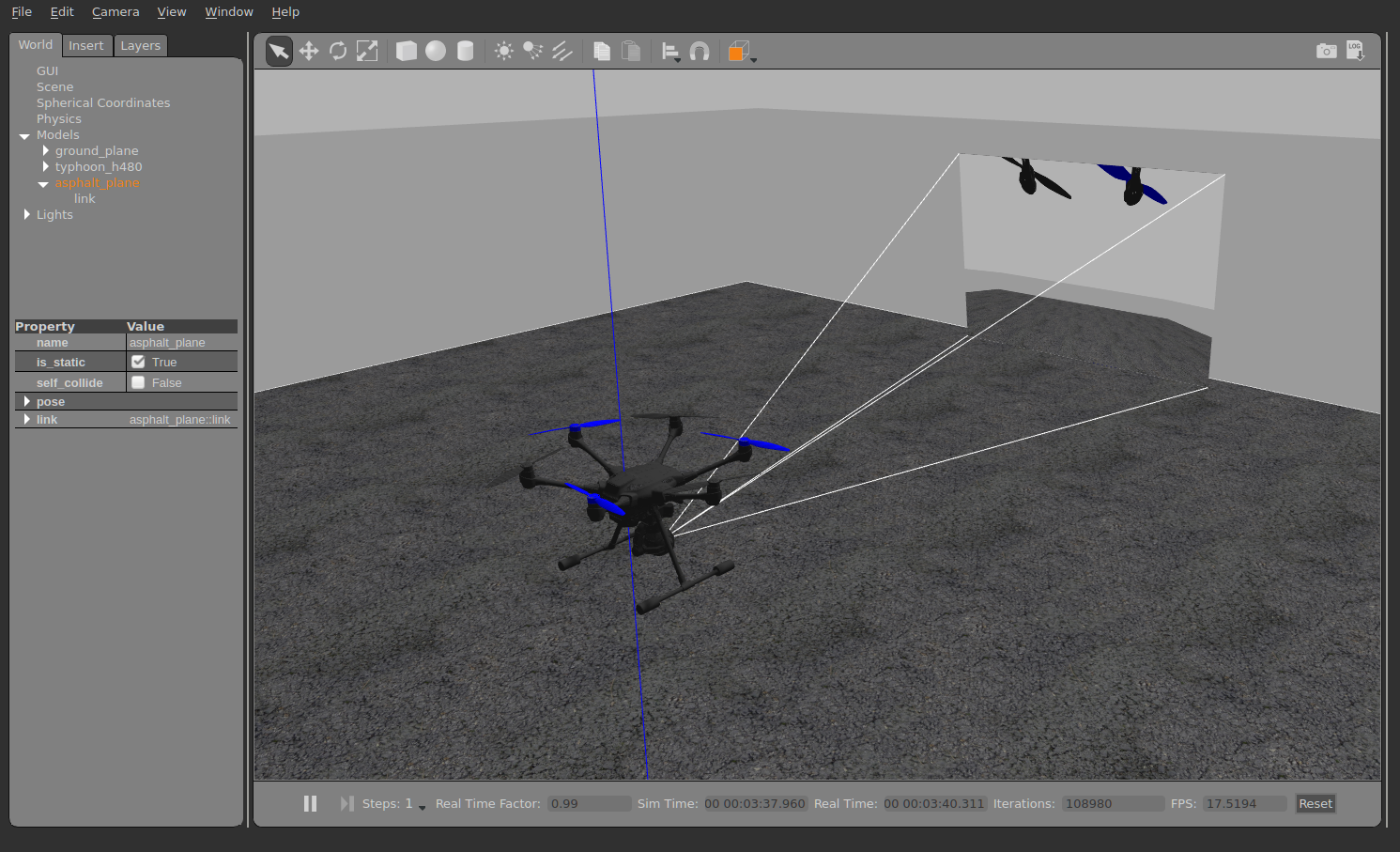

Vtol - APM, vtol

Vtol with single prop

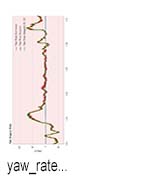

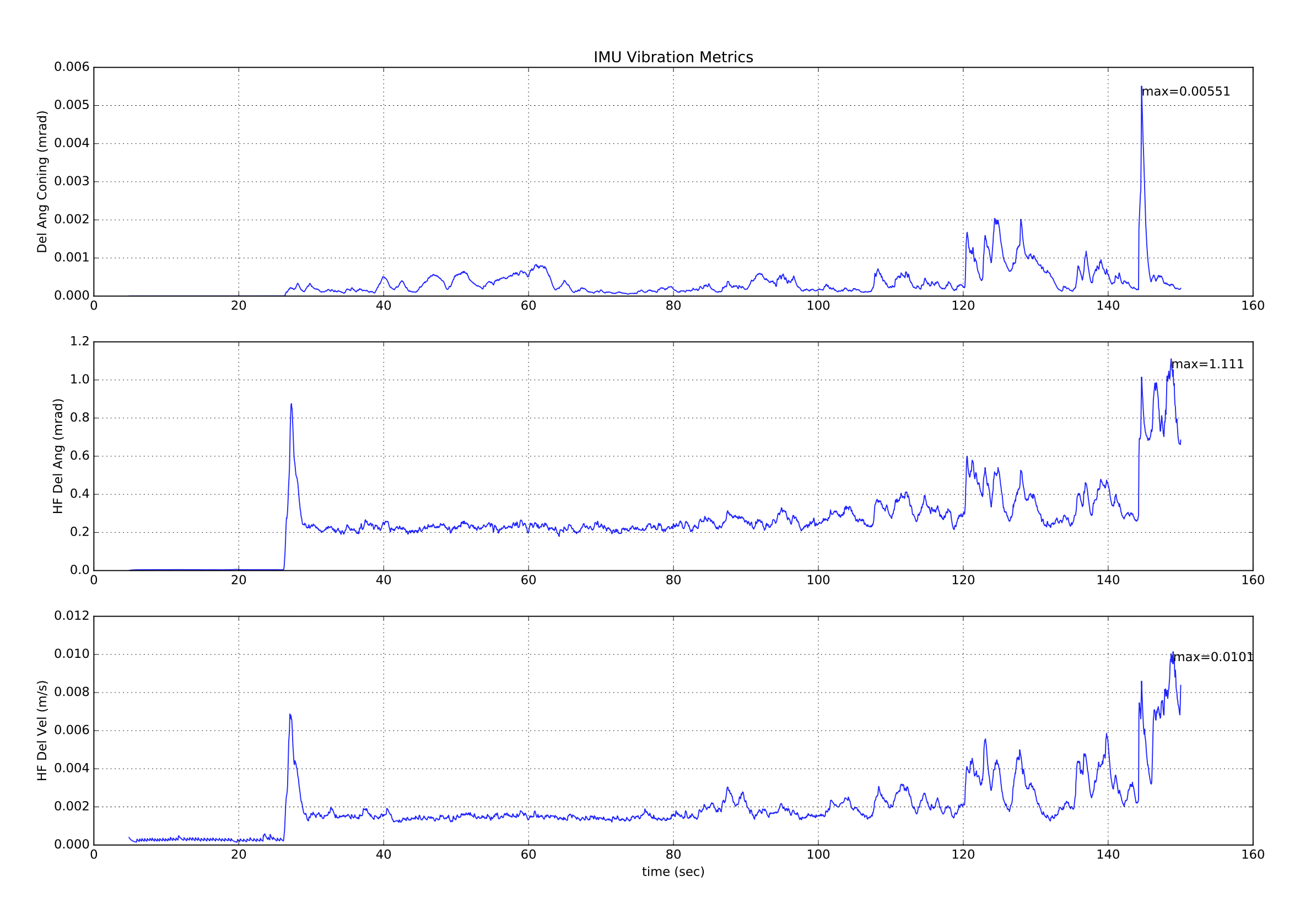

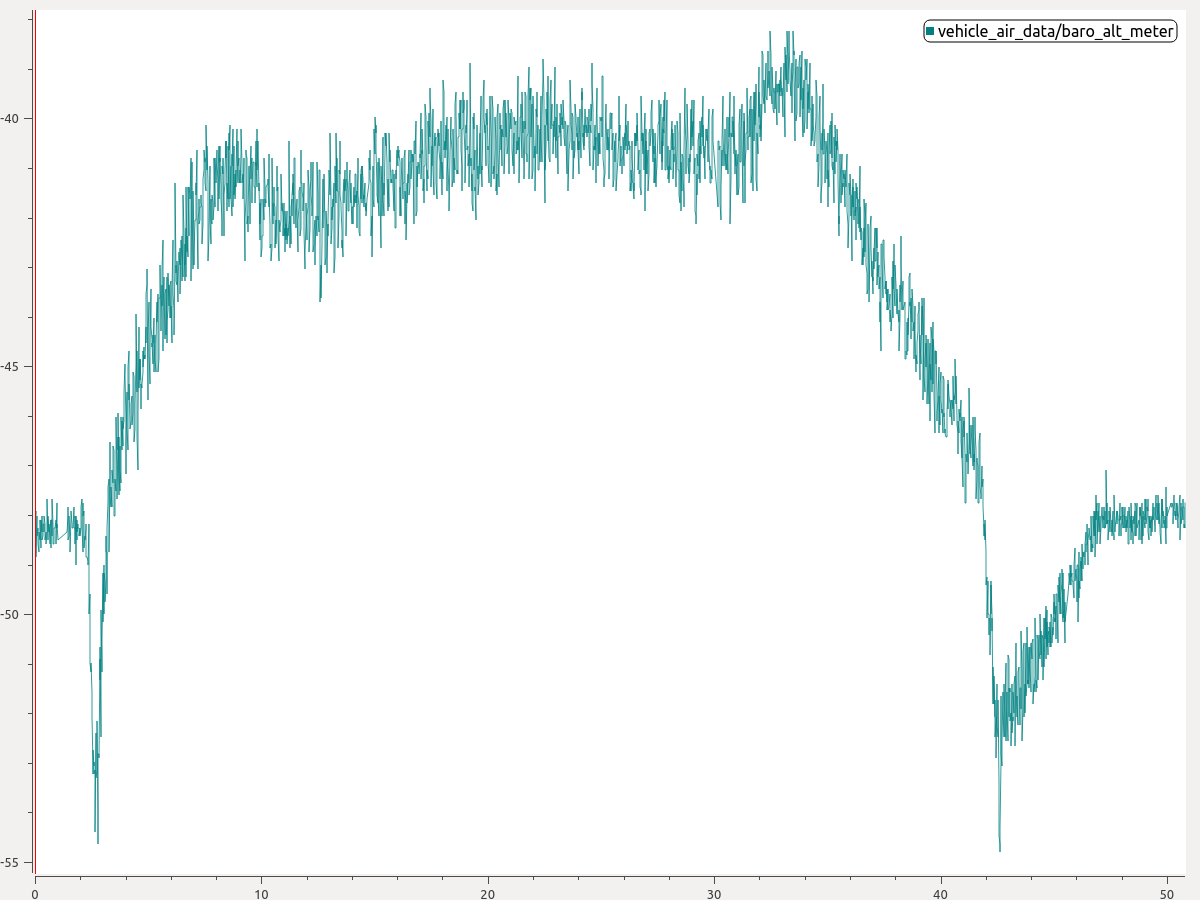

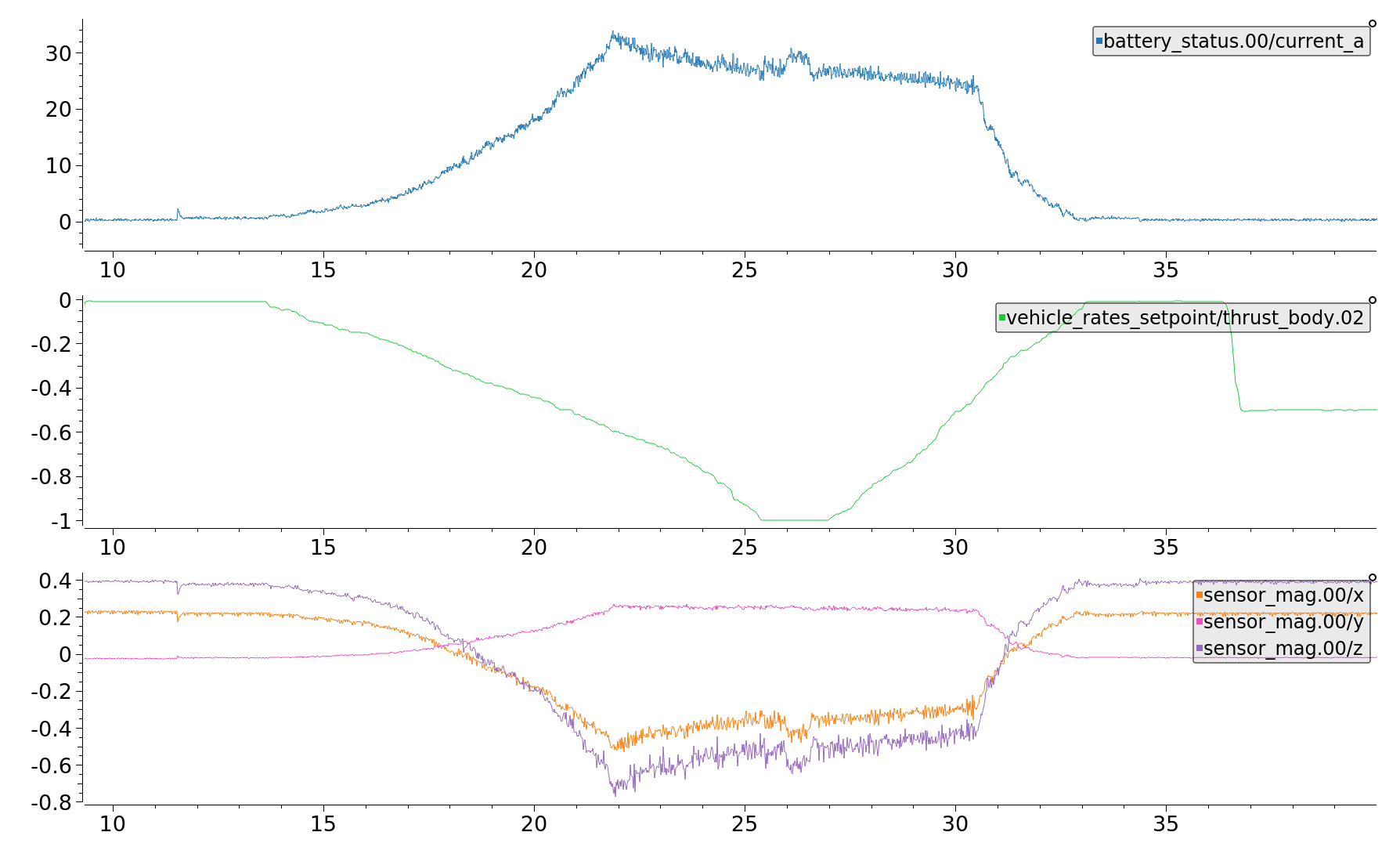

Follow up work from this post , we decided to go for another flight to get a better tuned pitch controller, rectify airspeed sensor problems and collect more flight data before we push for TECS tuning.

A few hypotheses that we have been thinking about:

- Vibrations from the DLE61 gas engine got to the Cube’s pitch estimation, causing the dive

- Looking at the attitude graphs, the system knew that pitch was going down. It was also desiring more and more pitch as the aircraft dove downwards.

- error_RP data from NKF4 seem to indicate small errors.

- Plane pitch controllers (set of PIDP data) also seem to indicate that PID loops are actively kicking in to bring aircraft back to level

- One thing we did notice is that there was a lot of clipping of accelerometers while aircraft is still on the ground. However, the clipping events stopped when aircraft is in the air.

- Given that we were able to do a QLOITER with an engine in idle @ 2700 RPM, we aren’t sure if sensors and estimation are the cause of the problem.

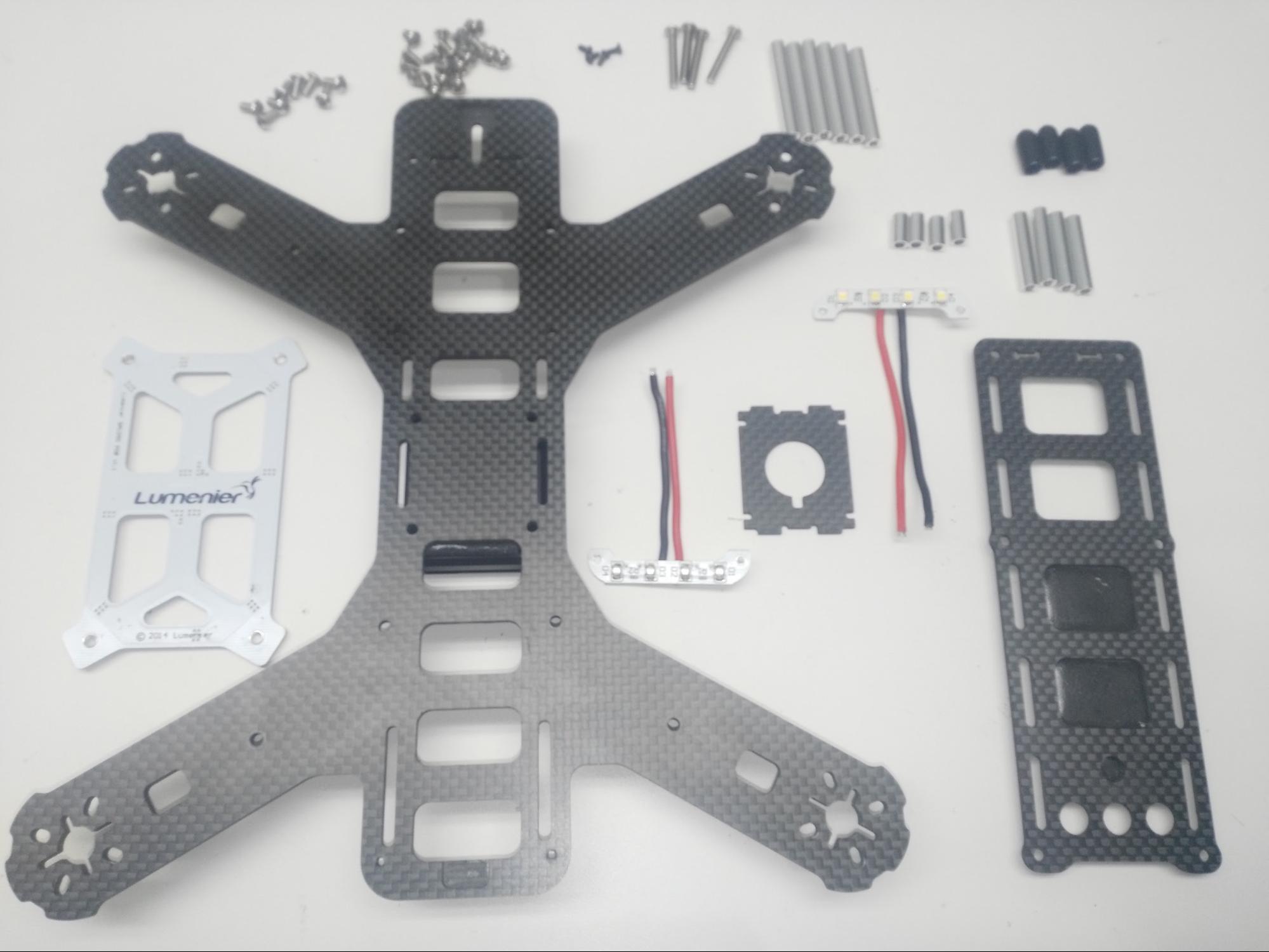

Racing Skyhero - APM, skyhero

Skyhero

| Type | Details | Type | Details |

|---|---|---|---|

| frame | FC | ||

| motor | ESC | ||

| RC | mode | ||

| weight | class | ||

| battery | air-time | ||

| configurator | last updated | ||

| airframe |

FC

Spacing f3 6dot

camera

Aomway

DJI s900 - DJI, Assistant, Spreadwings

DJI S900 Wookong

overview

| Type | Details | Type | Details |

|---|---|---|---|

| frame | FC | ||

| motor | ESC | ||

| RC | mode | ||

| weight | class | ||

| battery | air-time | ||

| configurator | last updated | ||

| airframe |

checklist and indicator status

- Servo power will shut off 3 seconds after the landing gear has reached its target position.

- When powering on the system, if the transmitter switch is in the [Upper] position, the LED will flash red quickly as a warning. Toggle the switch to the [Lower] position to continue.

- If there is an abnormal signal or no signal input into the “IN” port, the LED will slowly flash red. Check receiver and connections for problems.

- If servo power consumption is too high, the LED will light up red. If this lasts more than 4 seconds, the landing gear will lower and the LED will flash green slowly. Re-calibration is needed beforeflying.

- A2 flight control system users can use the A2 Assistant to set intelligent gear on the “Advanced” page. Refer to the “A2 user manual” for details

DJI s1000 - DJI, Assistant 2, Spreadwings

DJI S1000 A2

|

overview

| manual | training |

DJI s900 - DJI, Assistant, Spreadwings

DJI S1000 Wookong

overview

| Type | Details | Type | Details |

|---|---|---|---|

| frame | FC | ||

| motor | ESC | ||

| RC | mode | ||

| weight | class | ||

| battery | air-time | ||

| configurator | last updated | ||

| airframe spreadwings | from Gwangmyung |

checklist and indicator status

- Servo power will shut off 3 seconds after the landing gear has reached its target position.

- When powering on the system, if the transmitter switch is in the [Upper] position, the LED will flash red quickly as a warning. Toggle the switch to the [Lower] position to continue.

- If there is an abnormal signal or no signal input into the “IN” port, the LED will slowly flash red. Check receiver and connections for problems.

- If servo power consumption is too high, the LED will light up red. If this lasts more than 4 seconds, the landing gear will lower and the LED will flash green slowly. Re-calibration is needed beforeflying.

- A2 flight control system users can use the A2 Assistant to set intelligent gear on the “Advanced” page. Refer to the “A2 user manual” for details

DJI Quad - DJI, quad

dji quad custom frame

dji wookong with gimball

|

overview

pixhawk4 vision - APM, Mission-planner, autonomy

Pixhawk vision

nazam - DJI, Assistant

DJI Naza m Lite

|

|

|

| Type | Details | Type | Details |

|---|---|---|---|

| frame | FC | ||

| motor | ESC | ||

| RC | mode | ||

| weight | class | ||

| battery | air-time | ||

| configurator | last updated | ||

| airframe |

FC

Naza M Lite

_mydrone-readme - ros, apm, lora

overview

jetbot - nVidia, jetbot

Jetbot Nvidia Nano RAPA project

Follow me - APM, Mission-planner

Follow-Me Mode

- APM, Mission-planner

vibration isolation - APM, Mission-planner

Vibration Isolation

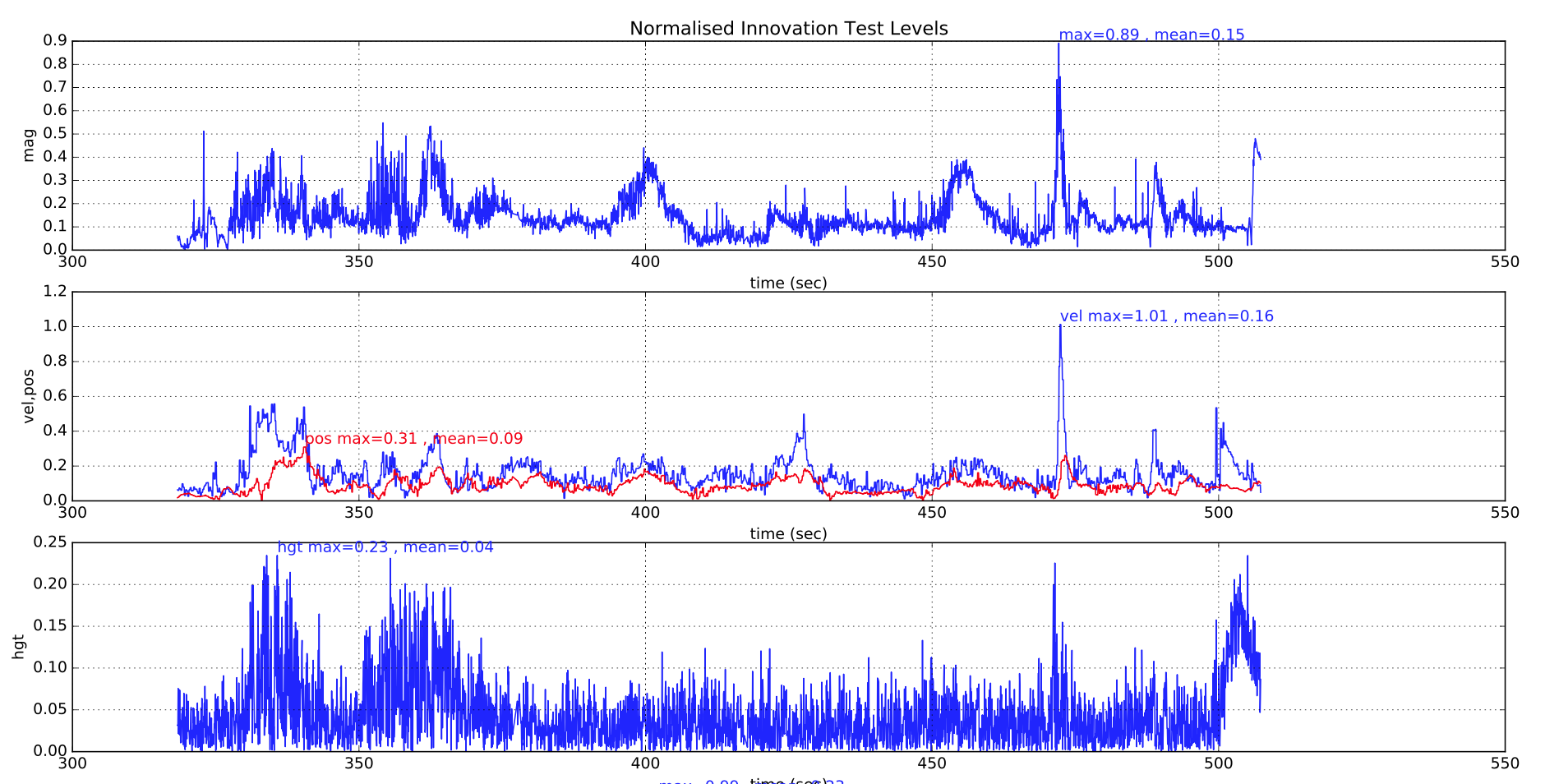

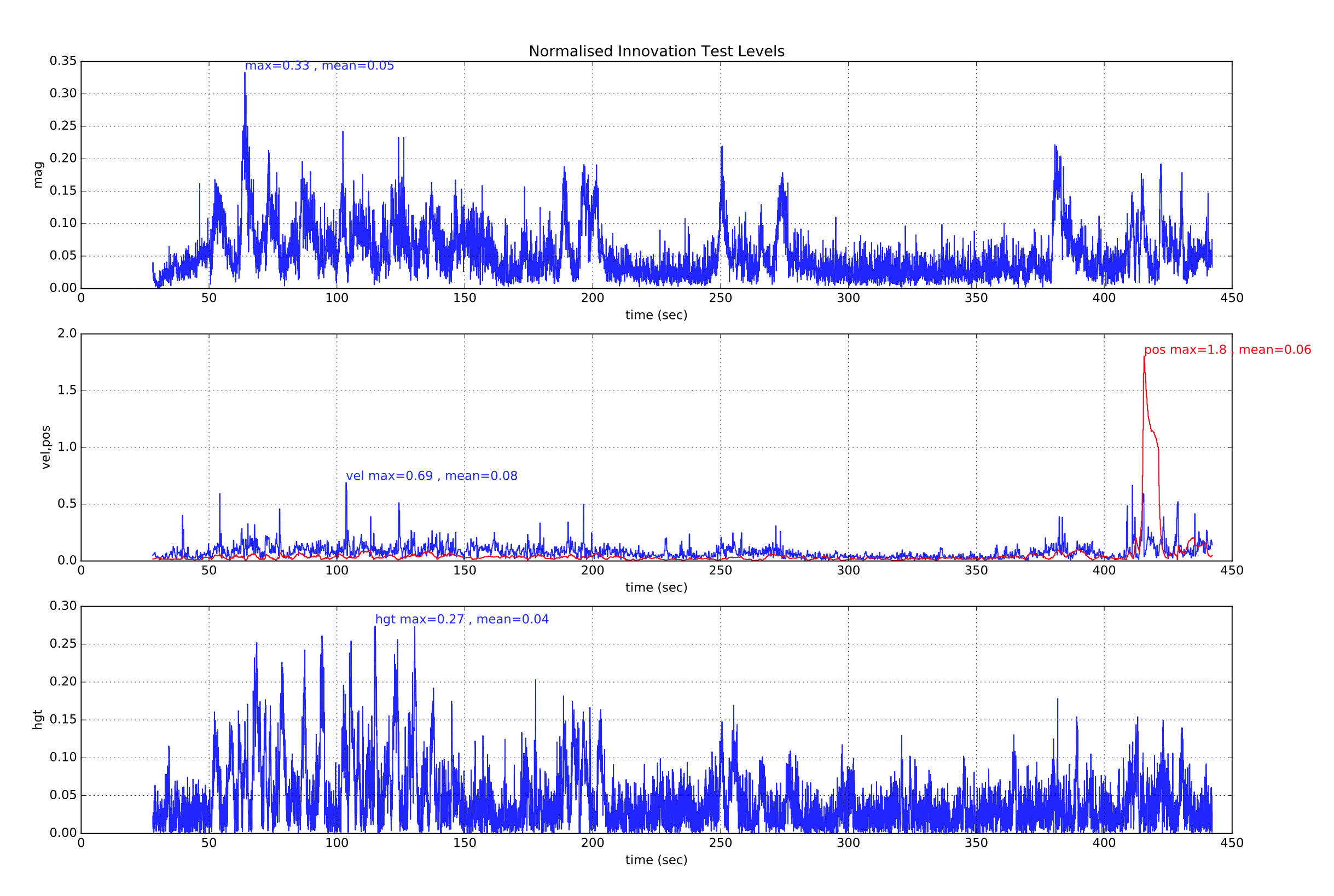

This topic shows how to determine whether vibration levels are too high, and lists some simple steps to improve vibration characteristics.

Overview

Flight Control boards with in-built accelerometers or gyros are sensitive to vibrations. High vibration levels can cause a range of problems, including reduced flight efficiency/performance, shorter flight times and increased vehicle wear-and-tear. In extreme cases vibration may lead to sensor clipping/failures, possibly resulting in estimation failures and fly-aways.

Well-designed airframes damp/reduce the amplitude of specific structural resonances at the autopilot mounting location. Further isolation may be needed in order to reduce vibration to the level that sensitive components can handle (e.g. some flight controllers must be attached to the airframe using some form of anti-vibration foam/mount - while others are internally isolated).

Vibration Analysis

Log Analysis using Flight Review > Vibration explains how to use logs to confirm whether vibration is a probable cause of flight problems.

Basic Vibration Fixes

A few of simple steps that may reduce vibrations are:

- Make sure everything is firmly attached on the vehicle (landing gear, GPS mast, etc.).

- Use balanced propellers.

- Make sure to use high-quality components for the propellers, motors, ESC and airframe. Each of these components can make a big difference.

- Use a vibration-isolation method to mount the autopilot. Many flight controllers come with mounting foam that you can use for this purpose, while others have inbuilt vibration-isolation mechanisms.

- As a last measure, adjust the software filters. It is better to reduce the source of vibrations, rather than filtering them out in software.

References

Some references that you may find useful are:

- An Introduction to Shock & Vibration Response Spectra, Tom Irvine (free paper)

- Structural Dynamics and Vibration in Practice - An Engineering Handbook, Douglas Thorby (preview).

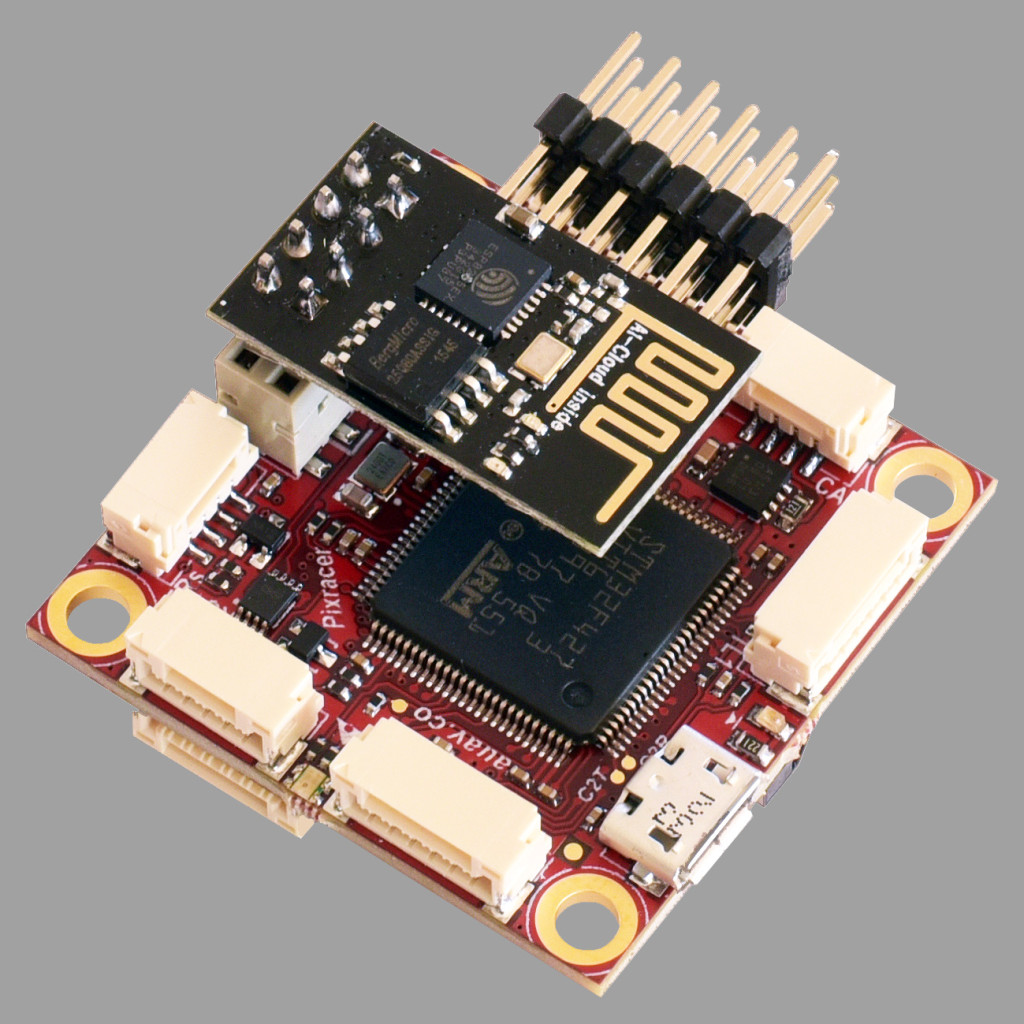

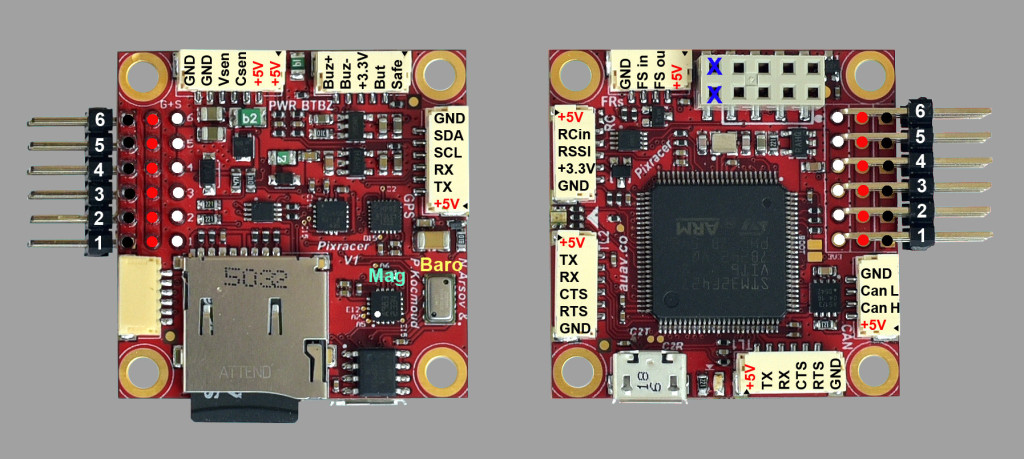

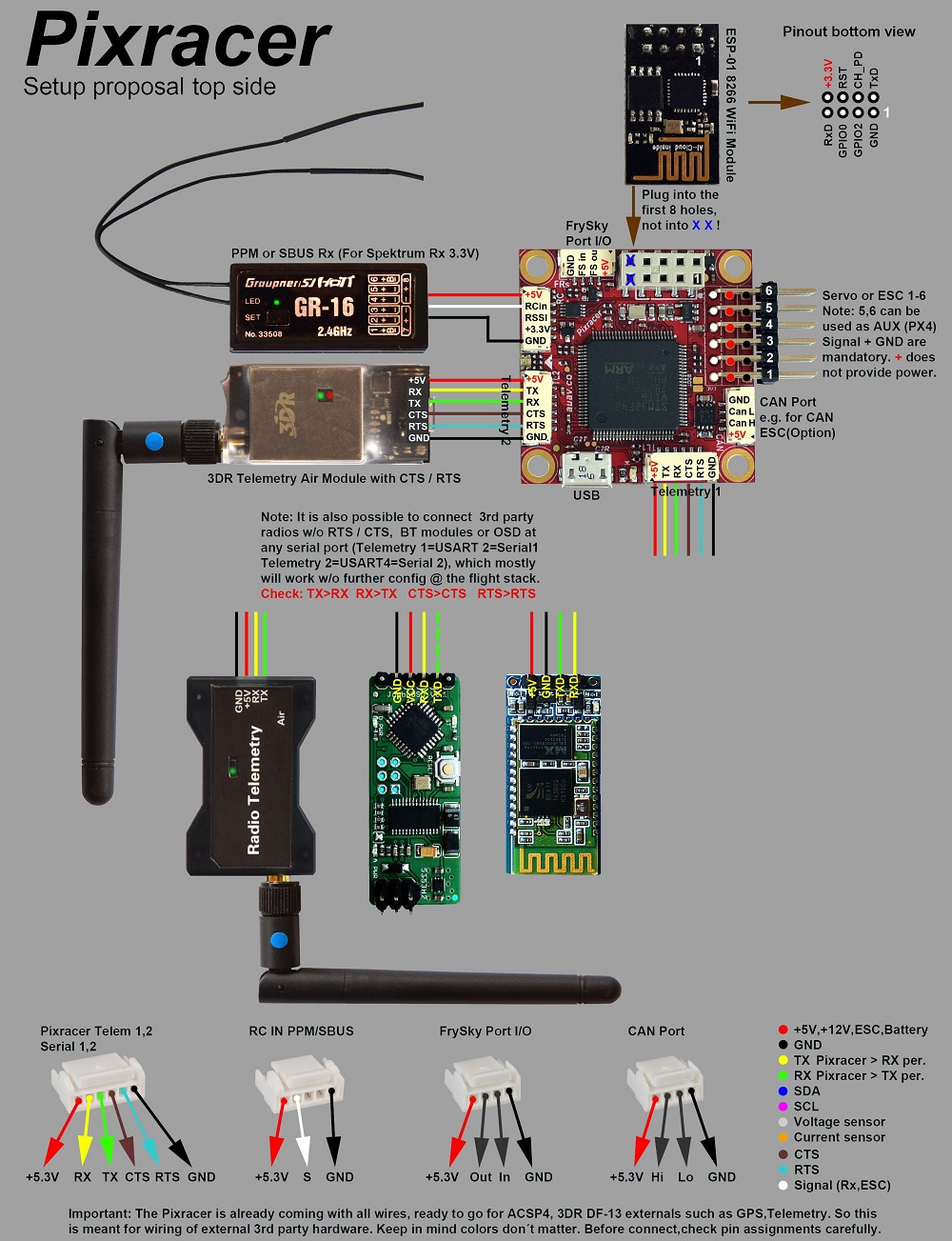

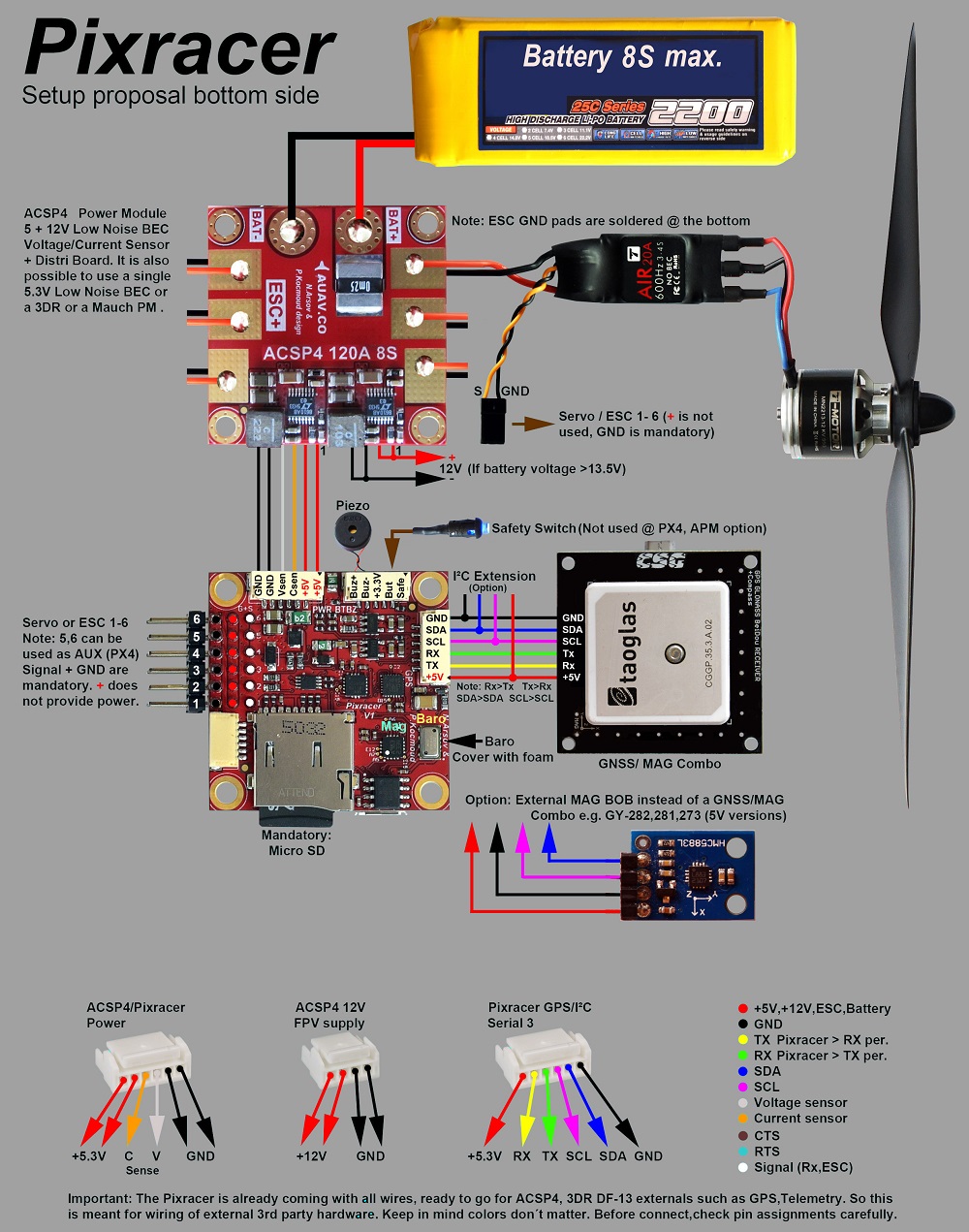

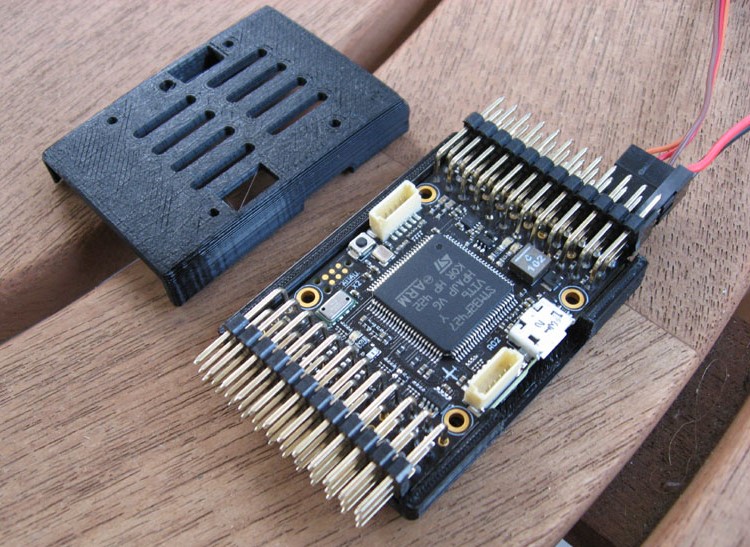

quick start pixracer - APM, Mission-planner

Pixracer Wiring Quick Start

:::warning PX4 does not manufacture this (or any) autopilot. Contact the manufacturer for hardware support or compliance issues. :::

:::warning Under construction :::

This quick start guide shows how to power the Pixracer flight controller and connect its most important peripherals.

Wiring Guides

Main Setup

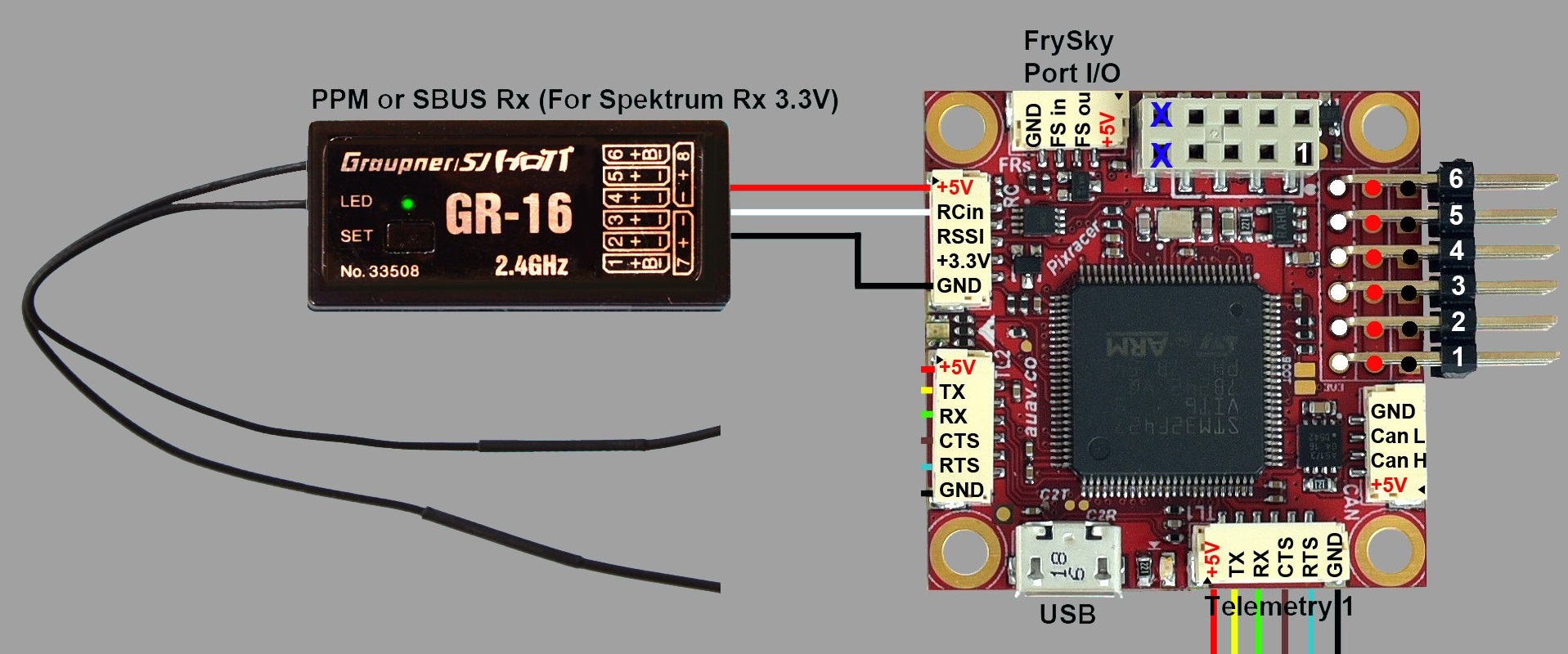

Radio/Remote Control

A remote control (RC) radio system is required if you want to manually control your vehicle (PX4 does not require a radio system for autonomous flight modes).

You will need to select a compatible transmitter/receiver and then bind them so that they communicate (read the instructions that come with your specific transmitter/receiver).

The instructions below show how to connect the different types of receivers:

-

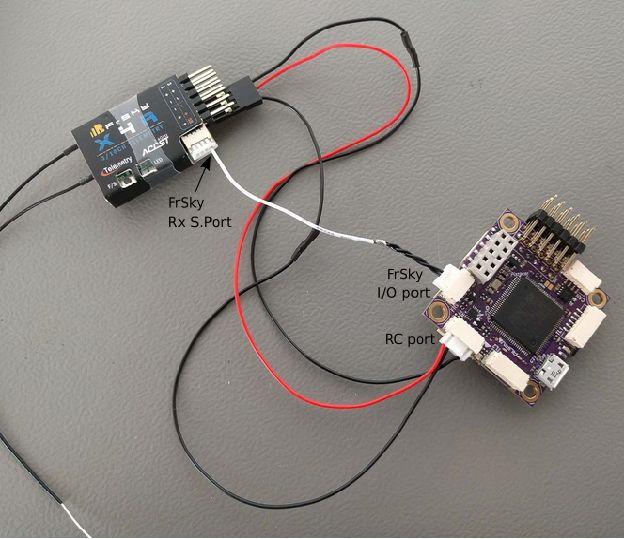

FrSky receivers connect via the port shown, and can use the provided I/O Connector.

-

PPM-SUM and S.BUS receivers connect to the RCIN port.

-

PPM and PWM receivers that have an individual wire for each channel must connect to the RCIN port via a PPM encoder like this one (PPM-Sum receivers use a single signal wire for all channels).

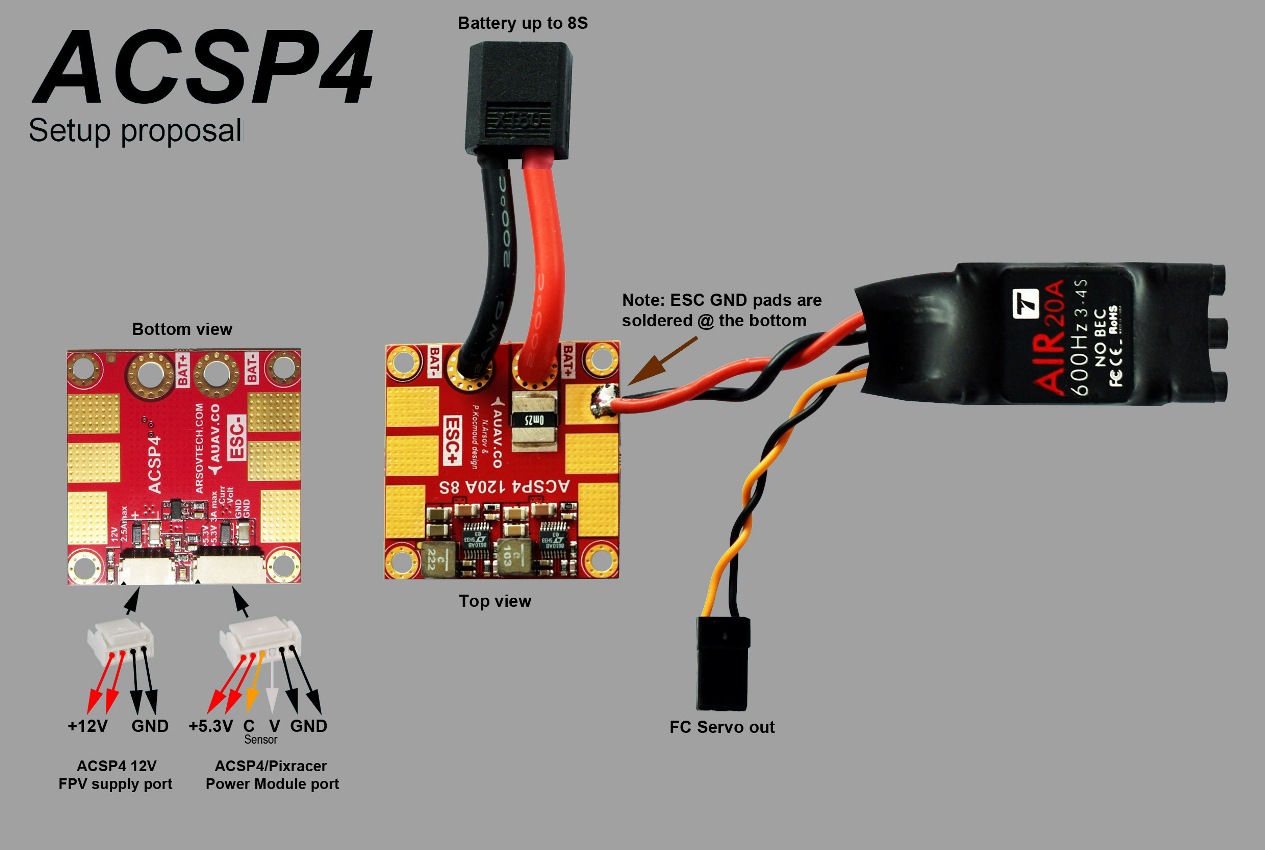

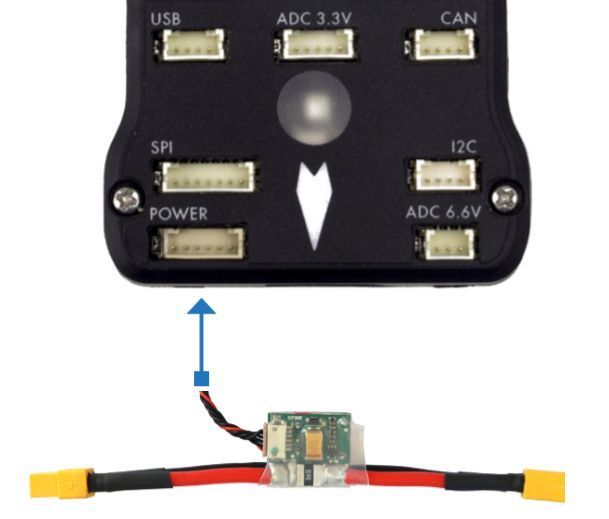

Power Module (ACSP4)

quick start pixhawk4 mini - APM, Mission-planner

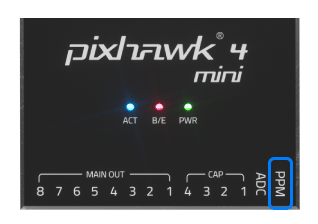

Pixhawk 4 Mini Wiring Quick Start

:::warning PX4 does not manufacture this (or any) autopilot. Contact the manufacturer for hardware support or compliance issues. :::

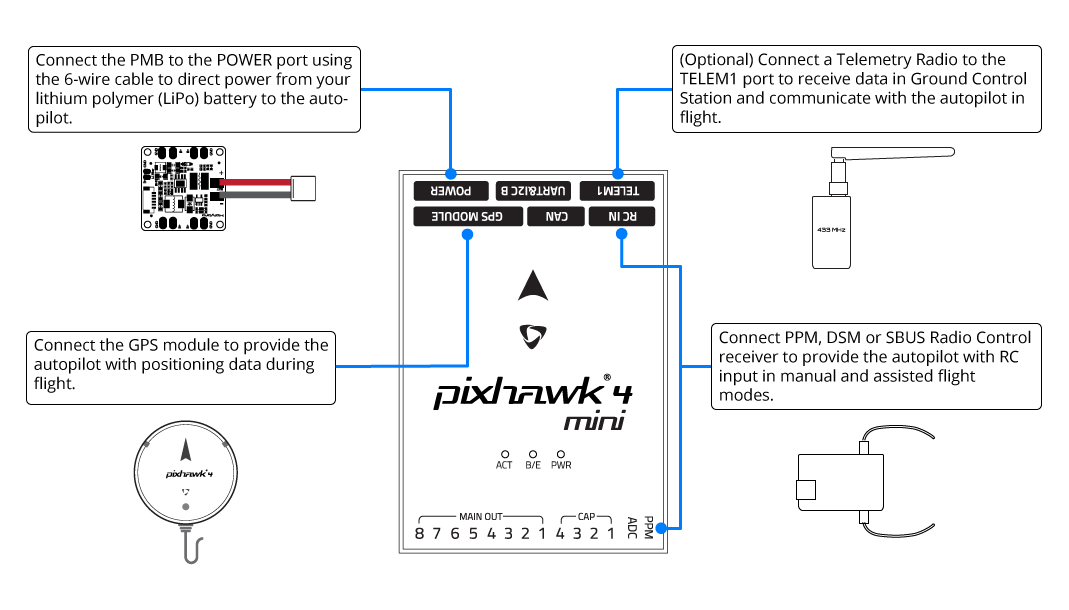

This quick start guide shows how to power the Pixhawk® 4 Mini flight controller and connect its most important peripherals.

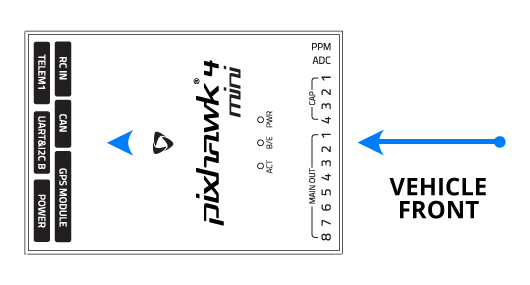

Wiring Chart Overview

The image below shows where to connect the most important sensors and peripherals (except for motors and servos).

:::tip More information about available ports can be found here: Pixhawk 4 Mini > Interfaces. :::

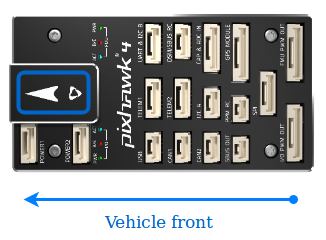

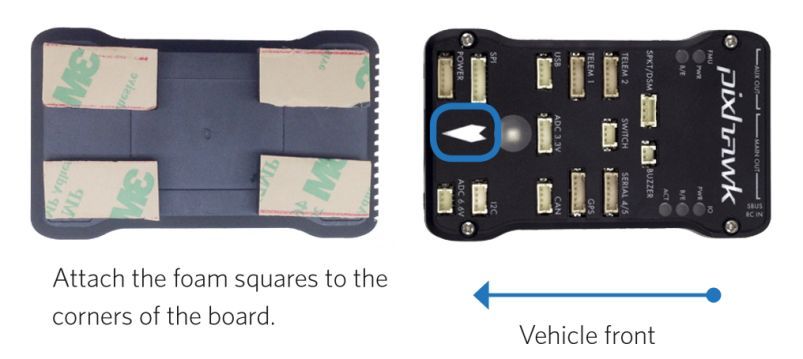

Mount and Orient Controller

Pixhawk 4 Mini should be mounted on your frame using vibration-damping foam pads (included in the kit). It should be positioned as close to your vehicle’s center of gravity as possible, oriented top-side up with the arrow pointing towards the front of the vehicle.

:::note If the controller cannot be mounted in the recommended/default orientation (e.g. due to space constraints) you will need to configure the autopilot software with the orientation that you actually used: Flight Controller Orientation. :::

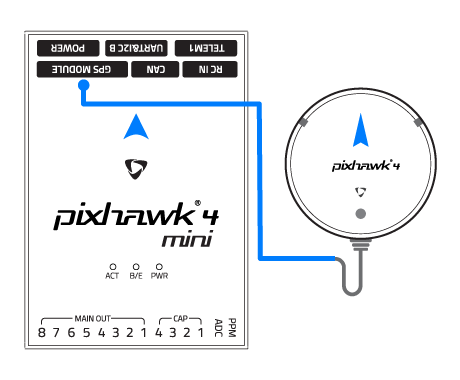

GPS + Compass + Buzzer + Safety Switch + LED

Attach the provided GPS with integrated compass, safety switch, buzzer, and LED to the GPS MODULE port. The GPS/Compass should be mounted on the frame as far away from other electronics as possible, with the direction marker towards the front of the vehicle (separating the compass from other electronics will reduce interference).

:::note The GPS module’s integrated safety switch is enabled by default (when enabled, PX4 will not let you arm the vehicle). To disable the safety press and hold the safety switch for 1 second. You can press the safety switch again to enable safety and disarm the vehicle (this can be useful if, for whatever reason, you are unable to disarm the vehicle from your remote control or ground station). :::

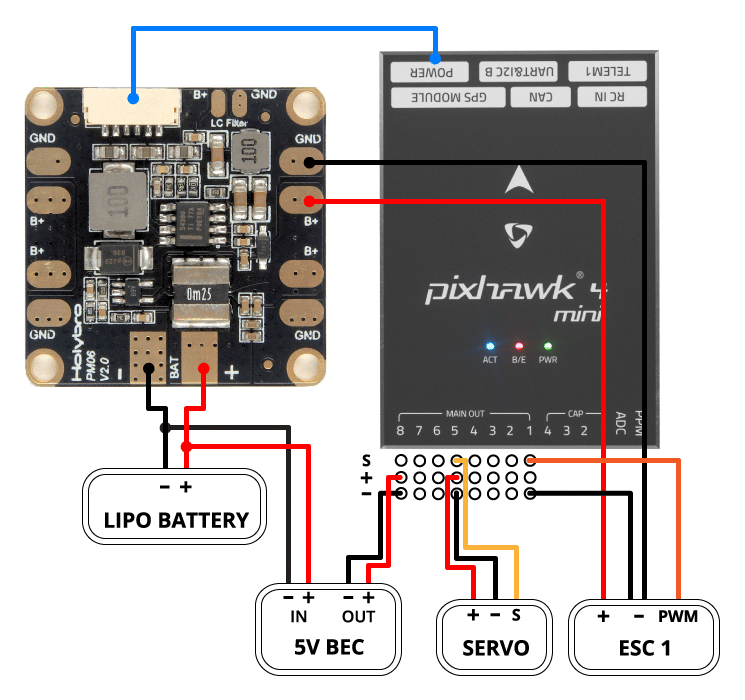

Power

The Power Management Board (PMB) serves the purpose of a power module as well as a power distribution board. In addition to providing regulated power to Pixhawk 4 Mini and the ESCs, it sends information to the autopilot about the battery’s voltage and current draw.

Connect the output of the PMB that comes with the kit to the POWER port of the Pixhawk 4 Mini using a 6-wire cable. The connections of the PMB, including power supply and signal connections to the ESCs and servos, are explained in the image below.

:::note The image above only shows the connection of a single ESC and a single servo. Connect the remaining ESCs and servos similarly. :::

| Pin(s) or Connector | Function |

|---|---|

| B+ | Connect to ESC B+ to power the ESC |

| GND | Connect to ESC Ground |

| PWR | JST-GH 6-pin Connector, 5V 3A output connect to Pixhawk 4 Mini POWER |

| BAT | Power Input, connect to 2~12s LiPo Battery |

The pinout of the Pixhawk 4 Mini POWER port is shown below.

The CURRENT signal should carry an analog voltage from 0-3.3V for 0-120A as default.

The VOLTAGE signal should carry an analog voltage from 0-3.3V for 0-60V as default.

The VCC lines have to offer at least 3A continuous and should default to 5.1V. A lower voltage of 5V is still acceptable, but discouraged.

| Pin | Signal | Volt |

|---|---|---|

| 1(red) | VCC | +5V |

| 2(black) | VCC | +5V |

| 3(black) | CURRENT | +3.3V |

| 4(black) | VOLTAGE | +3.3V |

| 5(black) | GND | GND |

| 6(black) | GND | GND |

:::note If using a plane or rover, the 8 pin power (+) rail of MAIN OUT will need to be separately powered in order to drive servos for rudders, elevons, etc. To do this, the power rail needs to be connected to a BEC equipped ESC, a standalone 5V BEC, or a 2S LiPo battery. Be careful with the voltage of servo you are going to use here. :::

:::note Using the Power Module that comes with the kit you will need to configure the Number of Cells in the Power Settings but you won’t need to calibrate the voltage divider. You will have to update the voltage divider if you are using any other power module (e.g. the one from the Pixracer). :::

Radio Control

A remote control (RC) radio system is required if you want to manually control your vehicle (PX4 does not require a radio system for autonomous flight modes).

You will need to select a compatible transmitter/receiver and then bind them so that they communicate (read the instructions that come with your specific transmitter/receiver).

The instructions below show how to connect the different types of receivers to Pixhawk 4 Mini:

-

Spektrum/DSM or S.BUS receivers connect to the DSM/SBUS RC input.

-

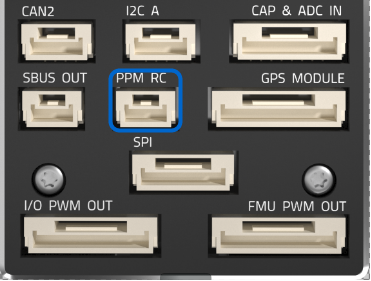

PPM receivers connect to the PPM RC input port.

-

PPM and PWM receivers that have an individual wire for each channel must connect to the PPM RC port via a PPM encoder like this one (PPM-Sum receivers use a single signal wire for all channels).

For more information about selecting a radio system, receiver compatibility, and binding your transmitter/receiver pair, see: Remote Control Transmitters & Receivers.

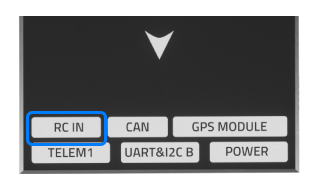

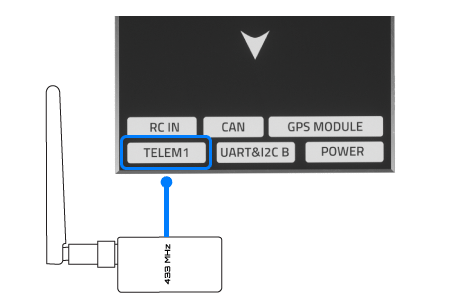

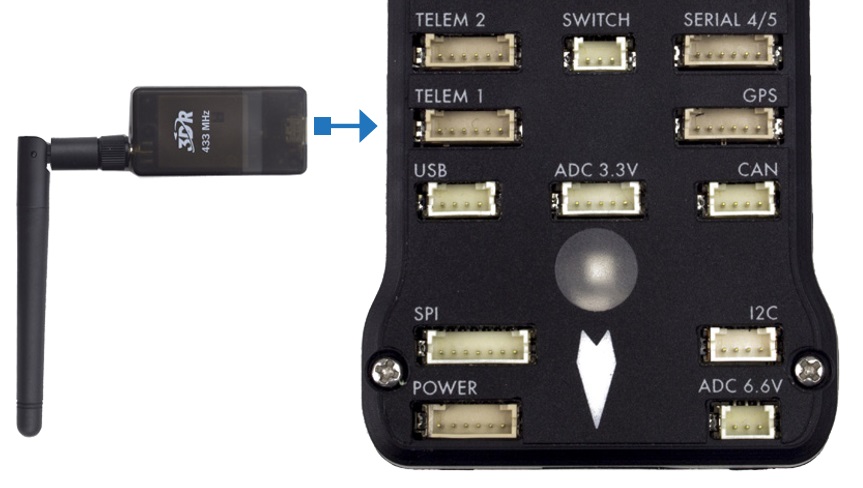

Telemetry Radio (Optional)

Telemetry radios may be used to communicate and control a vehicle in flight from a ground station (for example, you can direct the UAV to a particular position, or upload a new mission).

The vehicle-based radio should be connected to the TELEM1 port as shown below (if connected to this port, no further configuration is required). The other radio is connected to your ground station computer or mobile device (usually by USB).

microSD Card (Optional)

SD cards are highly recommended as they are needed to log and analyse flight details, to run missions, and to use UAVCAN-bus hardware. Insert the card (included in the kit) into Pixhawk 4 Mini as shown below.

:::tip For more information see Basic Concepts > SD Cards (Removable Memory). :::

Motors

Motors/servos are connected to the MAIN OUT ports in the order specified for your vehicle in the Airframe Reference. See Pixhawk 4 Mini > Supported Platforms for more information.

:::note This reference lists the output port to motor/servo mapping for all supported air and ground frames (if your frame is not listed in the reference then use a “generic” airframe of the correct type). :::

:::caution The mapping is not consistent across frames (e.g. you can’t rely on the throttle being on the same output for all plane frames). Make sure to use the correct mapping for your vehicle. :::

Other Peripherals

The wiring and configuration of optional/less common components is covered within the topics for individual peripherals.

Configuration

General configuration information is covered in: Autopilot Configuration.

QuadPlane specific configuration is covered here: QuadPlane VTOL Configuration

Further information

quick start pixhawk4 - APM, Mission-planner

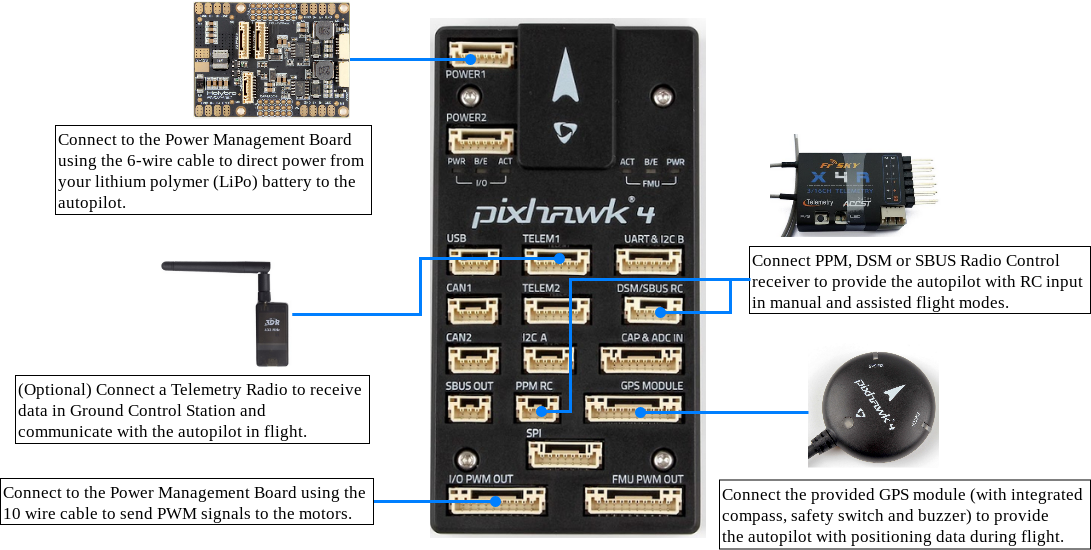

Pixhawk 4 Wiring Quick Start

:::warning PX4 does not manufacture this (or any) autopilot. Contact the manufacturer for hardware support or compliance issues. :::

This quick start guide shows how to power the Pixhawk 4® flight controller and connect its most important peripherals.

Wiring Chart Overview

The image below shows how to connect the most important sensors and peripherals (except the motor and servo outputs). We’ll go through each of these in detail in the following sections.

:::tip More information about available ports can be found here: Pixhawk 4 > Connections. :::

Mount and Orient Controller

Pixhawk 4 should be mounted on the frame using vibration-damping foam pads (included in the kit). It should be positioned as close to your vehicle’s center of gravity as possible, oriented top-side up with the arrow pointing towards the front of the vehicle.

:::note If the controller cannot be mounted in the recommended/default orientation (e.g. due to space constraints) you will need to configure the autopilot software with the orientation that you actually used: Flight Controller Orientation. :::

GPS + Compass + Buzzer + Safety Switch + LED

Attach the provided GPS with integrated compass, safety switch, buzzer and LED to the GPS MODULE port.

The GPS/Compass should be mounted on the frame as far away from other electronics as possible, with the direction marker towards the front of the vehicle (separating the compass from other electronics will reduce interference).

:::note The GPS module’s integrated safety switch is enabled by default (when enabled, PX4 will not let you arm the vehicle). To disable the safety press and hold the safety switch for 1 second. You can press the safety switch again to enable safety and disarm the vehicle (this can be useful if, for whatever reason, you are unable to disarm the vehicle from your remote control or ground station). :::

Power

Connect the output of the Power Management Board (PM board) that comes with the kit to one of the POWER bricks of Pixhawk 4 using a 6-wire cable. The PM input 2~12S will be connected to your LiPo battery. The connections of Power Management Board, including power supply and signal connections to the ESCs and servos, are explained in the table below. Note that the PM board does not supply power to the servos via + and - pins of FMU PWM-OUT.

The image below shows the power management board provided with Pixhawk 4.

:::note If using a plane or rover, the 8 pin power (+) rail of FMU PWM-OUT will need to be separately powered in order to drive servos for rudders, elevons etc. To do this, the power rail needs to be connected to a BEC equipped ESC or a standalone 5V BEC or a 2S LiPo battery. Be careful with the voltage of servo you are going to use here. :::

| PIN&Connector | Function |

|---|---|

| I/O PWM-IN | See note below for connection to Pixhawk 4 |

| M1 | I/O PWM OUT 1: connect signal wire to ESC of motor 1 here |

| M2 | I/O PWM OUT 2: connect signal wire to ESC of motor 2 here |

| M3 | I/O PWM OUT 3: connect signal wire to ESC of motor 3 here |

| M4 | I/O PWM OUT 4: connect signal wire to ESC of motor 4 here |

| M5 | I/O PWM OUT 5: connect signal wire to ESC of motor 5 here |

| M6 | I/O PWM OUT 6: connect signal wire to ESC of motor 6 here |

| M7 | I/O PWM OUT 7: connect signal wire to ESC of motor 7 here |

| M8 | I/O PWM OUT 8: connect signal wire to ESC of motor 8 here |

| FMU PWM-IN | See note below for connection to Pixhawk 4 |

| FMU PWM-OUT | If FMU PWM-IN is connected to Pixhawk 4, connect signal wires to ESC or signal, +, - wires to servos here |

| CAP&ADC-OUT | connect to CAP & ADC IN port of Pixhawk 4 |

| CAP&ADC-IN | CAP&ADC input: Pinouts are printed on the back side of the board |

| B+ | connect to ESC B+ to power the ESC |

| GND | connect to ESC Ground |

| PWR1 | 5v output 3A, connect to Pixhawk 4 POWER 1 |

| PWR2 | 5v output 3A, connect to Pixhawk 4 POWER 2 |

| 2~12S | Power Input, connect to 12S LiPo Battery |

:::note Depending on your airframe type, refer to Airframe Reference to connect I/O PWM OUT and FMU PWM OUT ports of Pixhawk 4 to PM board. MAIN outputs in PX4 firmware map to I/O PWM OUT port of Pixhawk 4 whereas AUX outputs map to FMU PWM OUT of Pixhawk 4. For example, MAIN1 maps to IO_CH1 pin of I/O PWM OUT and AUX1 maps to FMU_CH1 pin of FMU PWM OUT. FMU PWM-IN of PM board is internally connected to FMU PWM-OUT, which is used to drive servos (e.g. aileron, elevator, rudder, elevon, gear, flaps, gimbal, steering). I/O PWM-IN of PM board is internally connected to M1-8, which is used to drive motors (e.g. throttle in Plane, VTOL and Rover). :::

The following table summarizes how to connect Pixhawk 4’s PWM OUT ports to PM board’s PWM-IN ports, depending on the Airframe Reference.

| Airframe Reference | Connection between Pixhawk 4 –> PM board |

|---|---|

| MAIN: motor | I/O PWM OUT –> I/O PWM IN |

| MAIN: servo | I/O PWM OUT –> FMU PWM IN |

| AUX: motor | FMU PWM OUT –> I/O PWM IN |

| AUX: servo | FMU PWM OUT –> FMU PWM IN |

The pinout of Pixhawk 4’s power ports is shown below. The CURRENT signal should carry an analog voltage from 0-3.3V for 0-120A as default. The VOLTAGE signal should carry an analog voltage from 0-3.3V for 0-60V as default. The VCC lines have to offer at least 3A continuous and should default to 5.1V. A lower voltage of 5V is still acceptable, but discouraged.

| Pin | Signal | Volt |

|---|---|---|

| 1(red) | VCC | +5V |

| 2(black) | VCC | +5V |

| 3(black) | CURRENT | +3.3V |

| 4(black) | VOLTAGE | +3.3V |

| 5(black) | GND | GND |

| 6(black) | GND | GND |

:::note Using the Power Module that comes with the kit you will need to configure the Number of Cells in the Power Settings but you won’t need to calibrate the voltage divider. You will have to update the voltage divider if you are using any other power module (e.g. the one from the Pixracer). :::

Radio Control

A remote control (RC) radio system is required if you want to manually control your vehicle (PX4 does not require a radio system for autonomous flight modes).

You will need to select a compatible transmitter/receiver and then bind them so that they communicate (read the instructions that come with your specific transmitter/receiver).

The instructions below show how to connect the different types of receivers to Pixhawk 4:

-

Spektrum/DSM or S.BUS receivers connect to the DSM/SBUS RC input.

-

PPM receivers connect to the PPM RC input port.

-

PPM and PWM receivers that have an individual wire for each channel must connect to the PPM RC port via a PPM encoder like this one (PPM-Sum receivers use a single signal wire for all channels).

For more information about selecting a radio system, receiver compatibility, and binding your transmitter/receiver pair, see: Remote Control Transmitters & Receivers.

Telemetry Radios (Optional)

Telemetry radios may be used to communicate and control a vehicle in flight from a ground station (for example, you can direct the UAV to a particular position, or upload a new mission).

The vehicle-based radio should be connected to the TELEM1 port as shown below (if connected to this port, no further configuration is required). The other radio is connected to your ground station computer or mobile device (usually by USB).

SD Card (Optional)

SD cards are highly recommended as they are needed to log and analyse flight details, to run missions, and to use UAVCAN-bus hardware. Insert the card (included in Pixhawk 4 kit) into Pixhawk 4 as shown below.

:::tip For more information see Basic Concepts > SD Cards (Removable Memory). :::

Motors

Motors/servos are connected to the I/O PWM OUT (MAIN) and FMU PWM OUT (AUX) ports in the order specified for your vehicle in the Airframe Reference.

:::note This reference lists the output port to motor/servo mapping for all supported air and ground frames (if your frame is not listed in the reference then use a “generic” airframe of the correct type). :::

:::caution The mapping is not consistent across frames (e.g. you can’t rely on the throttle being on the same output for all plane frames). Make sure to use the correct mapping for your vehicle. :::

Other Peripherals

The wiring and configuration of optional/less common components is covered within the topics for individual peripherals.

Pinouts

Pixhawk 4 Pinouts (Holybro)

Configuration

General configuration information is covered in: Autopilot Configuration.

QuadPlane specific configuration is covered here: QuadPlane VTOL Configuration

Further information

- Pixhawk 4 (Overview page)

- Pixhawk 4 Technical Data Sheet

- Pixhawk 4 Pinouts (Holybro)

- Pixhawk 4 Quick Start Guide (Holybro)

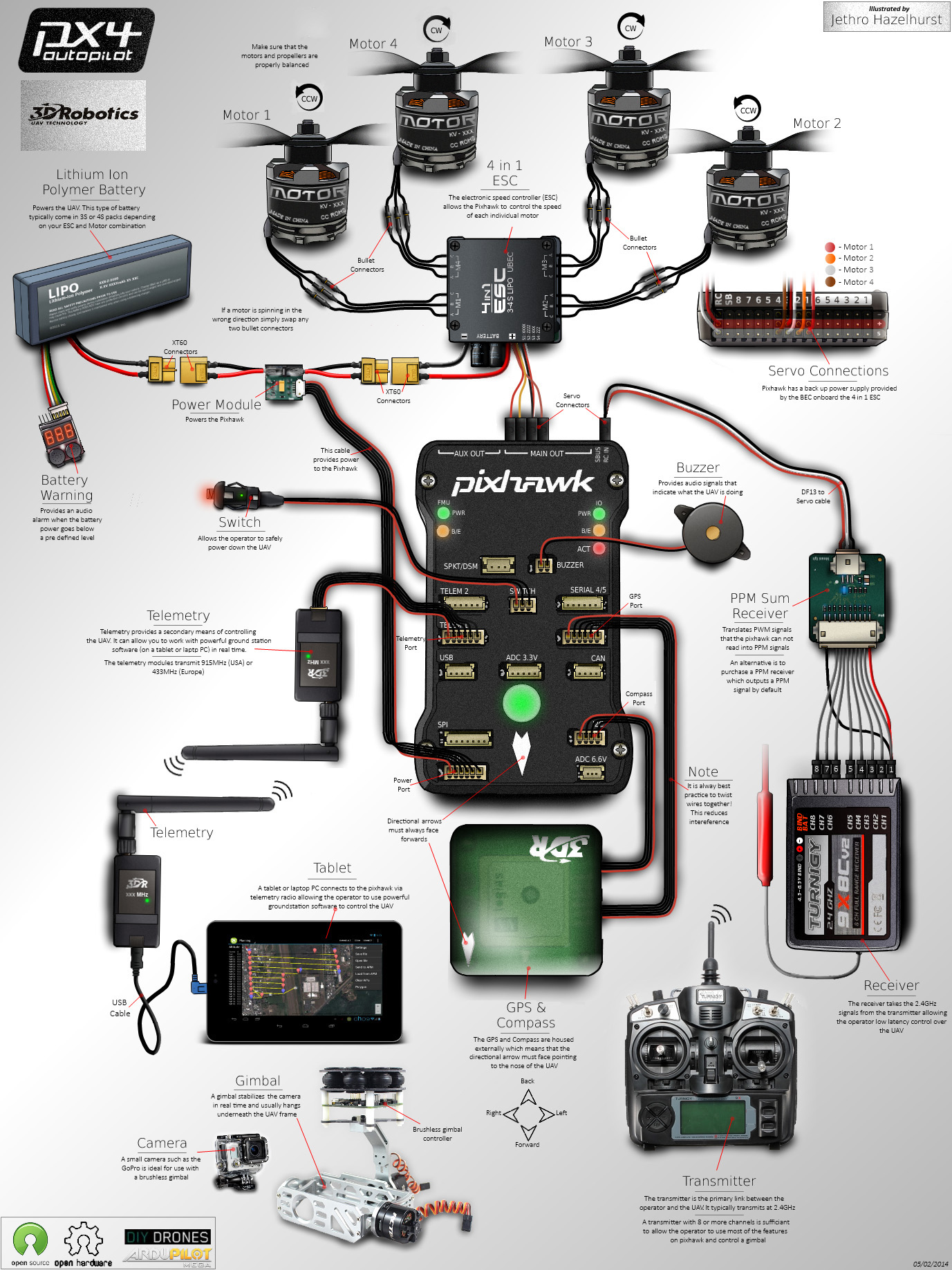

quick start pixhawk - APM, Mission-planner

Pixhawk Wiring Quick Start

:::warning PX4 does not manufacture this (or any) autopilot. Contact the manufacturer for hardware support or compliance issues. :::

This quick start guide shows how to power the 3DR Pixhawk flight controller and connect its most important peripherals.

:::note The 3DR Pixhawk is no longer available from 3DR. Other flight controllers based on the Pixhawk FMUv2 architecture are available from other companies (these share the same connections, outputs, functions, etc. and are wired in a similar way). :::

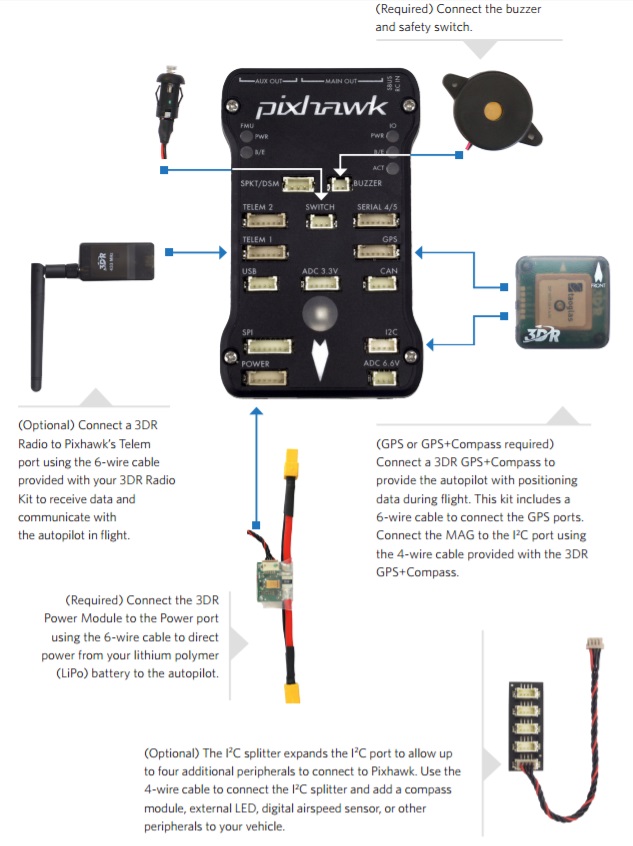

Wiring Chart Overview

The image below shows standard Pixhawk connections (excepting the motor and servo outputs). We’ll go through each main part in the following sections.

:::note More detailed wiring information is shown below. :::

Mount and Orient Controller

The Pixhawk should be mounted on the frame using vibration-damping foam pads (included in the kit). It should be positioned as close to your vehicle’s center of gravity as possible, oriented top-side up with the arrow points towards the front of the vehicle.

:::note If the controller cannot be mounted in the recommended/default orientation (e.g. due to space constraints) you will need to configure the autopilot software with the orientation that you actually used: Flight Controller Orientation. :::

Buzzer and Safety Switch

Connect the included buzzer and safety switch as shown below (these are mandatory).

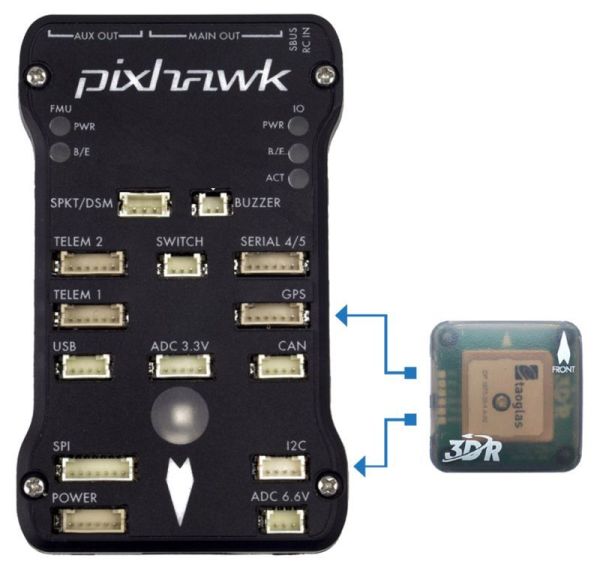

GPS + Compass

Attach a GPS (required) to the GPS port using the 6-wire cable supplied in the kit. Optionally attach a compass to the I2C port using a 4-wire cable (the Pixhawk has an internal compass, which can be used if necessary).

:::note The diagram shows a combined GPS and Compass. The GPS/Compass should be mounted on the frame as far away from other electronics as possible, with the direction marker towards the front of the vehicle (separating the compass from other electronics will reduce interference). :::

Power

Connect the output of a Power module (PM) to the POWER port using a 6-wire cable as shown. The PM input will be connected to your LiPo battery, while the main output will supply vehicle ESCs/motors (possibly via a power distribution board).

The power module supplies the flight controller with power from the battery and also sends information about the analog current and voltage supplied via the module (including both power to the flight controller and to motors etc).

:::warning The power module supplies the flight controller itself, but cannot power servos and other hardware connected to the controller’s output ports (rail). For copter this does not matter because the motors are separately powered. :::

For planes and VTOL the output rail will need to be separately powered in order to drive servos for rudders, elevons etc. Often the main pusher/puller motor uses an ESC with an integrated BEC that can be connected to the Pixhawk output rail. If not, you will need to setup a 5V BEC to connect to one of the free Pixhawk ports (without power, the servos will not work).

Radio Control

A remote control (RC) radio system is required if you want to manually control your vehicle (PX4 does not require a radio system for autonomous flight modes).

You will need to select a compatible transmitter/receiver and then bind them so that they communicate (read the instructions that come with your specific transmitter/receiver).

The instructions below show how to connect the different types of receivers to Pixhawk:

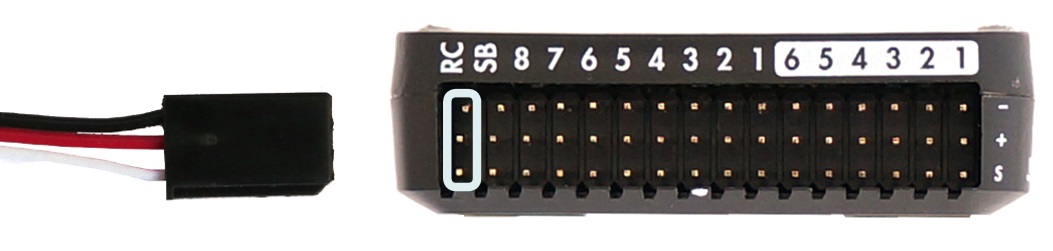

-

Spektrum and DSM receivers connect to the SPKT/DSM input.

-

PPM-SUM and S.BUS receivers connect to the RC ground, power and signal pins as shown.

-

PPM and PWM receivers that have an individual wire for each channel must connect to the RC port via a PPM encoder like this one (PPM-Sum receivers use a single signal wire for all channels).

For more information about selecting a radio system, receiver compatibility, and binding your transmitter/receiver pair, see: Remote Control Transmitters & Receivers.

Telemetry Radios (Optional)

Telemetry radios may be used to communicate and control a vehicle in flight from a ground station (for example, you can direct the UAV to a particular position, or upload a new mission). One radio must be connected to your vehicle as shown below. The other is connected to your ground station computer or mobile device (usually by USB).

Motors

The mappings between MAIN/AUX output ports and motor/servos for all supported air and ground frames are listed in the Airframe Reference.

:::caution The mapping is not consistent across frames (e.g. you can’t rely on the throttle being on the same output for all plane frames). Make sure to use the correct mapping for your vehicle. :::

:::tip If your frame is not listed in the reference then use a “generic” airframe of the correct type. :::

:::note The output rail must be separately powered, as discussed in the Power section above. :::

Other Peripherals

The wiring and configuration of other components is covered within the topics for individual peripherals.

Configuration

General configuration information is covered in: Autopilot Configuration.

QuadPlane specific configuration is covered here: QuadPlane VTOL Configuration

Detailed Wiring Infographic (Copter)

Further information

quick start holybro pix32 v5 - APM, Mission-planner

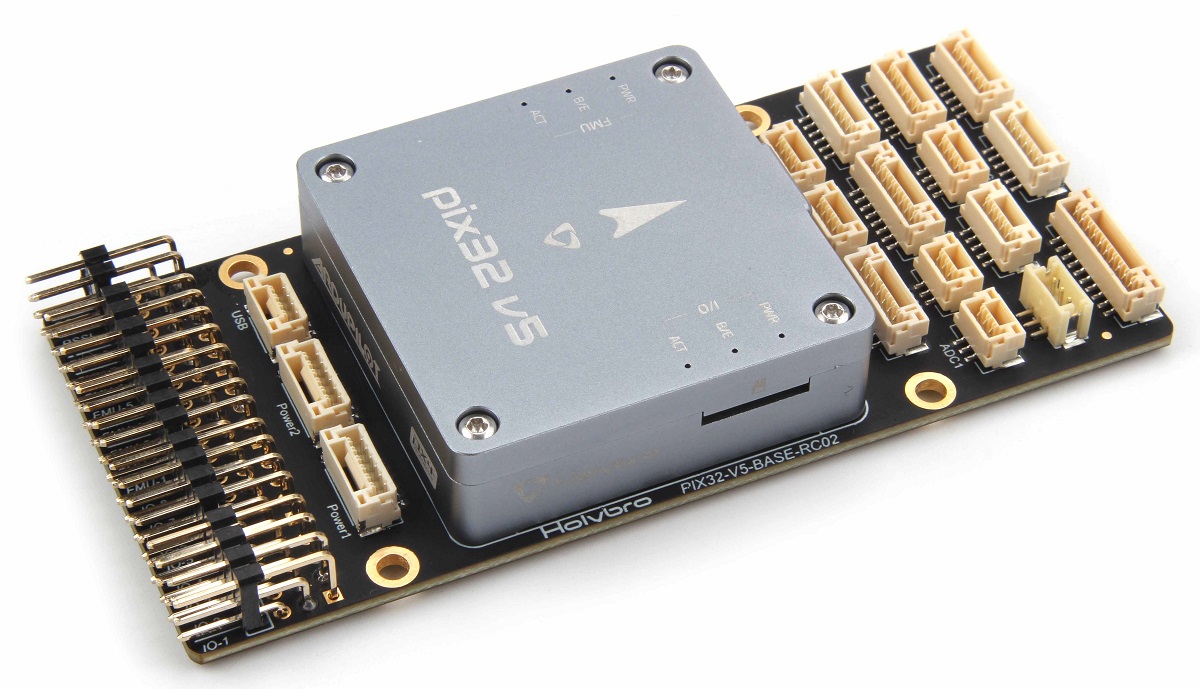

Pix32 v5 Wiring Quick Start

:::warning PX4 does not manufacture this (or any) autopilot. Contact the manufacturer for hardware support or compliance issues. :::

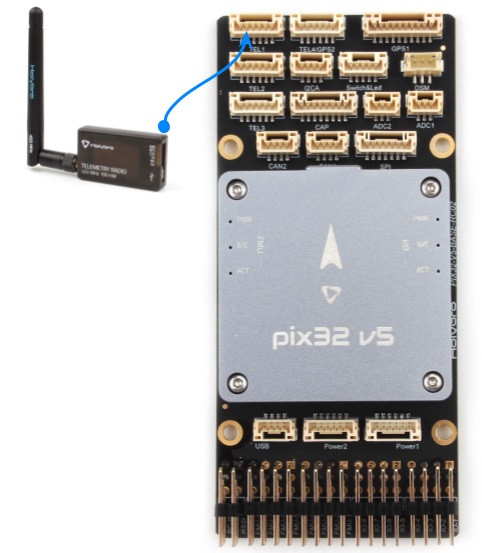

This quick start guide shows how to power the Holybro Pix32v5® flight controller and connect its most important peripherals.

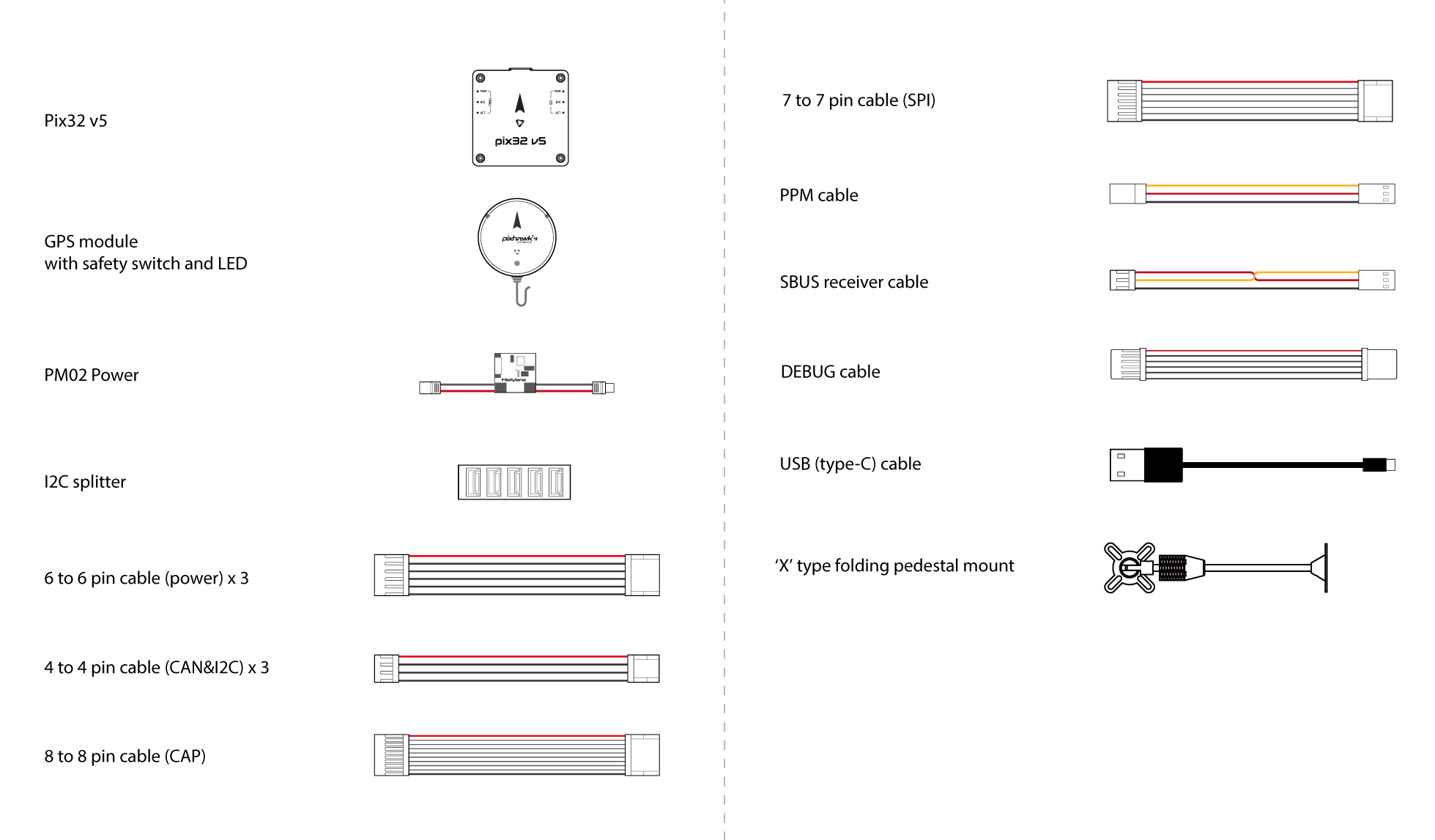

Unboxing

Pix32 v5 is sold bundled with a number of different combinations of accessories, including the pix32 v5 Base board, power module PM02 V3, and the Pixhawk 4 GPS/Compass (UBLOX NEO-M8N).

The content of the box with the PM02 V3 power module and Pixhawk 4 GPS/Compass is shown below. The box also includes a pinout guide and power module instructions, and Base board (not shown on the schematic below).

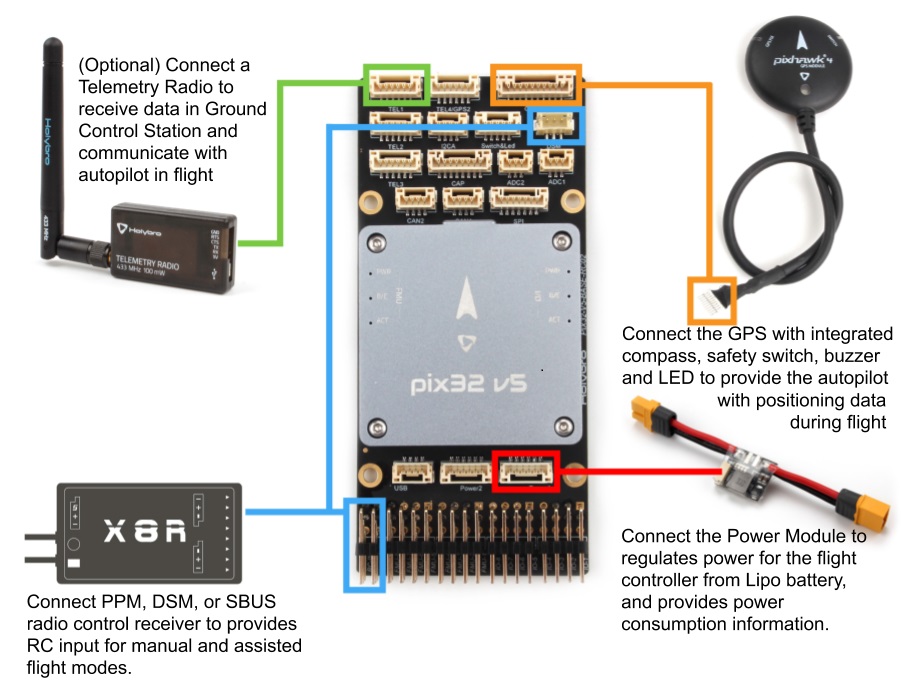

Wiring Chart Overview

The image below shows how to connect the most important sensors and peripherals (except the motor and servo outputs). We’ll go through each of these in detail in the following sections.

:::tip More information about available ports can be found here. :::

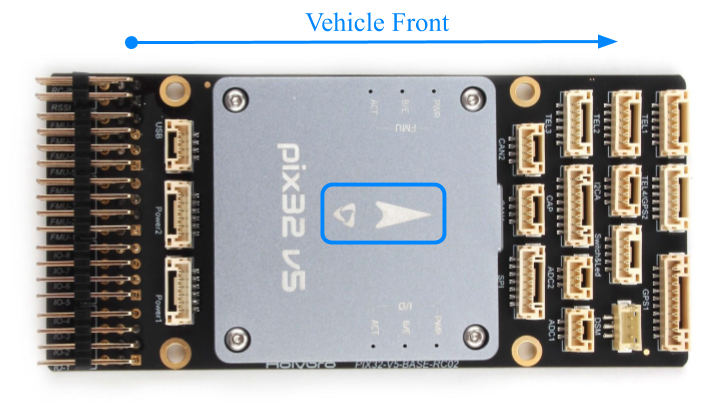

Mount and Orient Controller

Pix32 v5 should be mounted on the frame positioned as close to your vehicle’s center of gravity as possible, oriented top-side up with the arrow pointing towards the front of the vehicle.

:::note If the controller cannot be mounted in the recommended/default orientation (e.g. due to space constraints) you will need to configure the autopilot software with the orientation that you actually used: Flight Controller Orientation. :::

:::tip The board has internal vibration-isolation. Do not use vibration-isolation foam to mount the controller (double sided tape is normally sufficient). :::

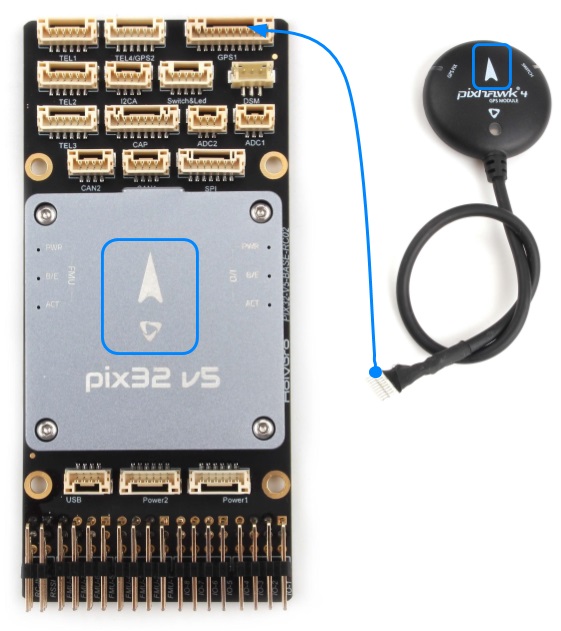

GPS + Compass + Buzzer + Safety Switch + LED

Pix32 v5 is designed to work well with the Pixhawk 4 GPS module, which has an integrated compass, safety switch, buzzer and LED. It connects directly to the GPS port using the 10 pin cable.

The GPS/Compass should be mounted on the frame as far away from other electronics as possible, with the direction marker towards the front of the vehicle (separating the compass from other electronics will reduce interference).

:::note The GPS module’s integrated safety switch is enabled by default (when enabled, PX4 will not let you arm the vehicle). To disable the safety press and hold the safety switch for 1 second. You can press the safety switch again to enable safety and disarm the vehicle (this can be useful if, for whatever reason, you are unable to disarm the vehicle from your remote control or ground station). :::

Power

You can use a power module or power distribution board to power motors/servos and measure power consumption. The recommended power modules are shown below.

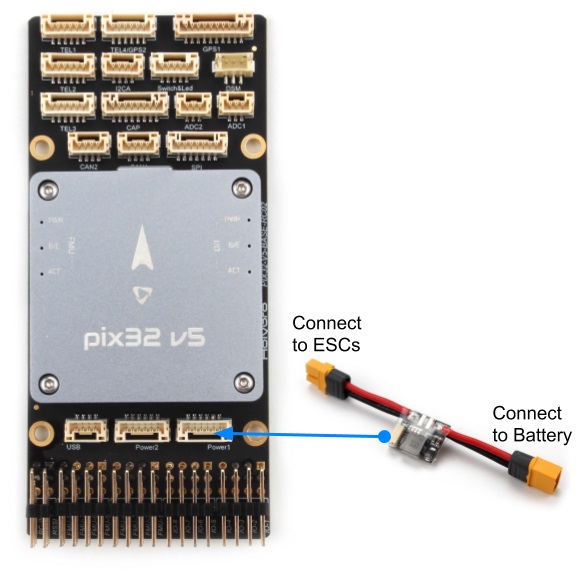

PM02 v3 Power Module

The Power Module (PM02 v3) can be bundled with pix32 v5. It provides regulated power to flight controller and sends battery voltage/current to the flight controller.

Connect the output of the Power Module as shown.

- PM voltage/current port: connect to POWER1 port (or

POWER2) using the 6-wire GH cable supplied. - PM input (XT60 male connector): connect to the LiPo battery (2~12S).

- PM power output (XT60 female connector): wire out to any motor ESCs.

:::note As this power module does not include power distribution wiring, you would normally just connect all the ESCs in parallel to the power module output (the ESC must be appropriate for the supplied voltage level). :::

:::note The 8 pin power (+) rail of MAIN/AUX is not powered by the power module supply to the flight controller. If it will need to be separately powered in order to drive servos for rudders, elevons etc., the power rail needs to be connected to a BEC equipped ESC or a standalone 5V BEC or a 2S LiPo battery. Ensure the voltage of servo you are going to use is appropriate. :::

The power module has the following characteristics/limits:

- Max input voltage: 60V

- Max current sensing: 120A Voltage

- Current measurement configured for SV ADC Switching regulator outputs 5.2V and 3A max

- Weight: 20g

- Package includes:

- PM02 board

- 6pin MLX cable (1)

- 6pin GH cable (1)

:::note See also PM02v3 Power Module Manual (Holybro). :::

Battery Configuration

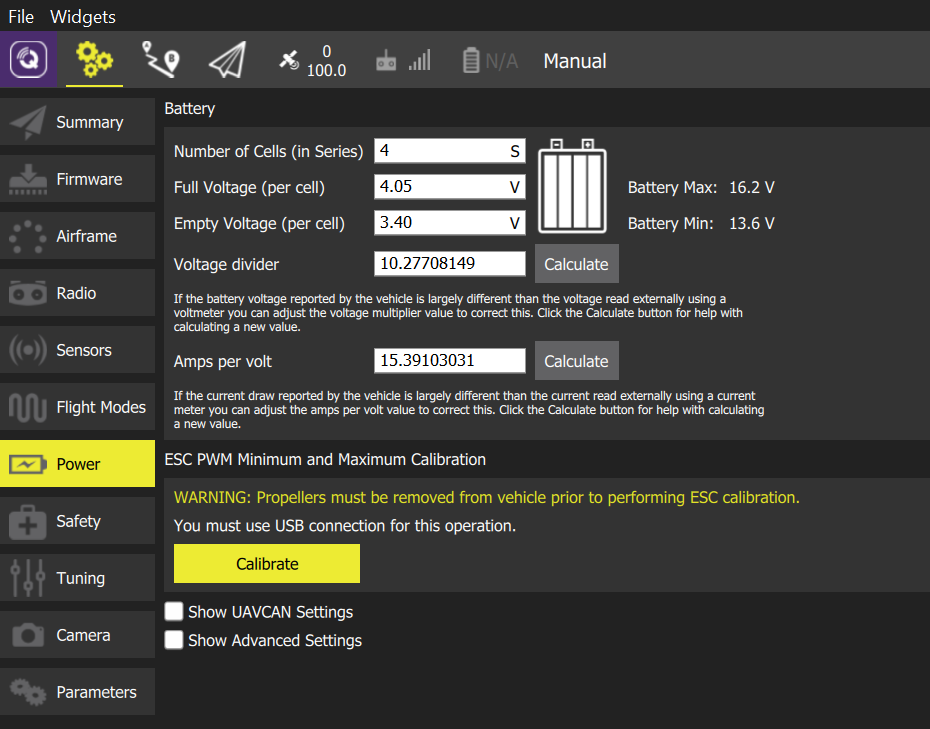

The battery/power setup must be configured in Power Settings. For either Power Module you will need to configure the Number of Cells.

You will not need to update the voltage divider unless you are using some other power module (e.g. the one from the Pixracer).

Radio Control

A remote control (RC) radio system is required if you want to manually control your vehicle (PX4 does not require a radio system for autonomous flight modes).

You will need to select a compatible transmitter/receiver and then bind them so that they communicate (read the instructions that come with your specific transmitter/receiver).

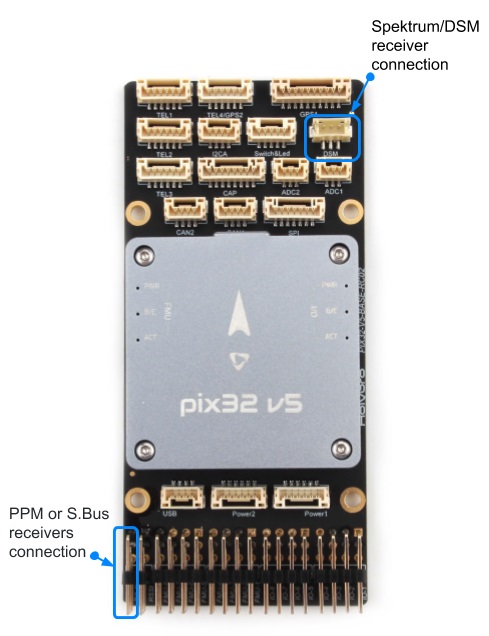

The instructions below show how to connect the different types of receivers to Pix32 v5 with Baseboard:

-

Spektrum/DSM receivers connect to the DSM RC input shown below.

-

PPM and S.Bus receivers connect to the SBUS_IN/PPM_IN input port (marked as RC IN):

-

PPM and PWM receivers that have an individual wire for each channel must connect to the PPM RC port via a PPM encoder like this one (PPM-Sum receivers use a single signal wire for all channels).

For more information about selecting a radio system, receiver compatibility, and binding your transmitter/receiver pair, see: Remote Control Transmitters & Receivers.

Telemetry Radios (Optional)

Telemetry radios may be used to communicate and control a vehicle in flight from a ground station (for example, you can direct the UAV to a particular position, or upload a new mission).

The vehicle-based radio should be connected to the TELEM1 port as shown below (if connected to this port, no further configuration is required). The other radio is connected to your ground station computer or mobile device (usually by USB).

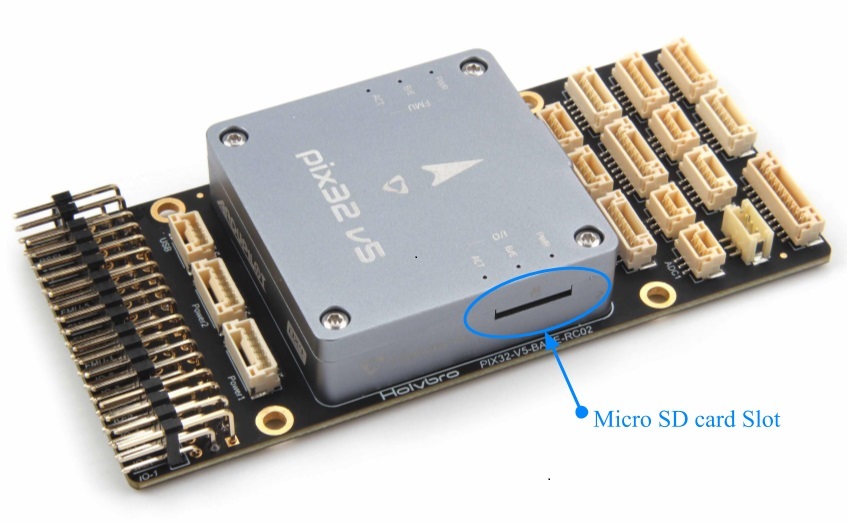

SD Card (Optional)

SD cards are most commonly used to log and analyse flight details. A micro SD card should come preinstalled on the pix32 v5, if you have your own micro SD card, insert the card into pix32 v5 as shown below.

:::tip The SanDisk Extreme U3 32GB is highly recommended. :::

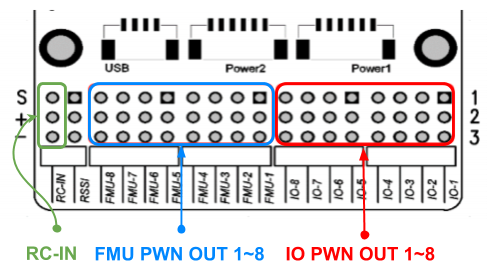

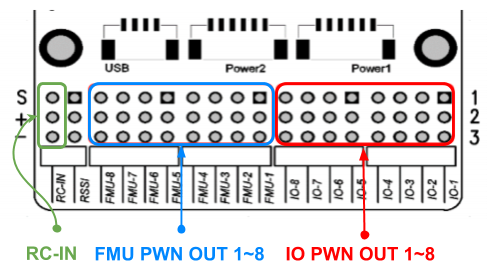

Motors

Motors/servos control signals are connected to the I/O PWM OUT (MAIN) and FMU PWM OUT (AUX) ports in the order specified for your vehicle in the Airframe Reference.

The motors must be separately powered.

:::note If your frame is not listed in the airframe reference then use a “generic” airframe of the correct type. :::

Other Peripherals

The wiring and configuration of optional/less common components is covered within the topics for individual peripherals.

Pinouts

Pix32 v5 Pinouts (Holybro)

Configuration

General configuration information is covered in: Autopilot Configuration.

QuadPlane specific configuration is covered here: QuadPlane VTOL Configuration

Further information

- Pix32 v5 Overview (Overview page)

- Pix32 v5 Technical Data Sheet

- Pix32 v5 Pinouts

- Pix32 v5 Base Schematic Diagram

- Pix32 v5 Base Components Layout

- FMUv5 reference design pinout.

quick start durandal - APM, Mission-planner

Durandal Wiring Quick Start

:::warning PX4 does not manufacture this (or any) autopilot. Contact the manufacturer for hardware support or compliance issues. :::

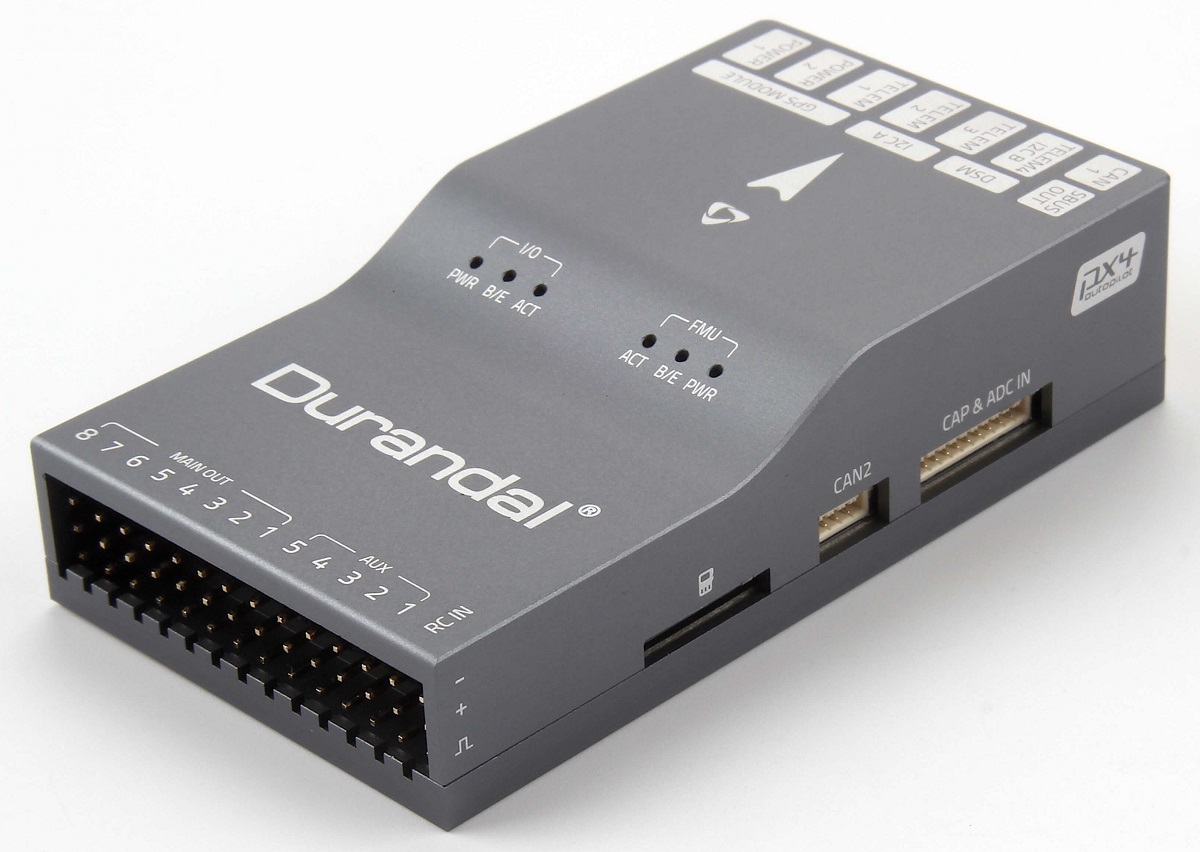

This quick start guide shows how to power the Holybro Durandal® flight controller and connect its most important peripherals.

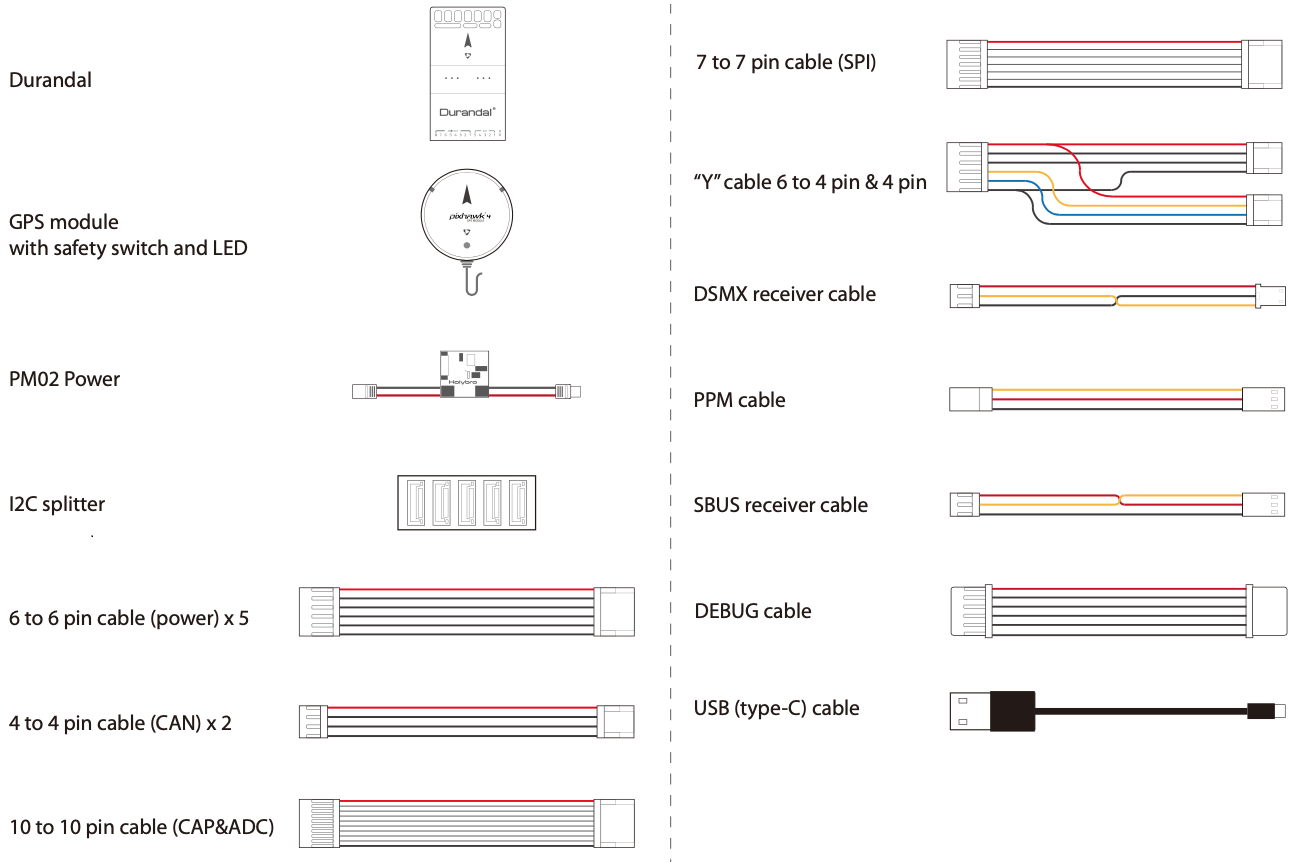

Unboxing

Durandal is sold bundled with a number of different combinations of accessories, including power modules: PM02 V3 and PM07, and the Pixhawk 4 GPS/Compass ( u-blox NEO-M8N).

The content of the box with the PM02 V3 power module is shown below (the box also includes a pinout guide and power module instructions).

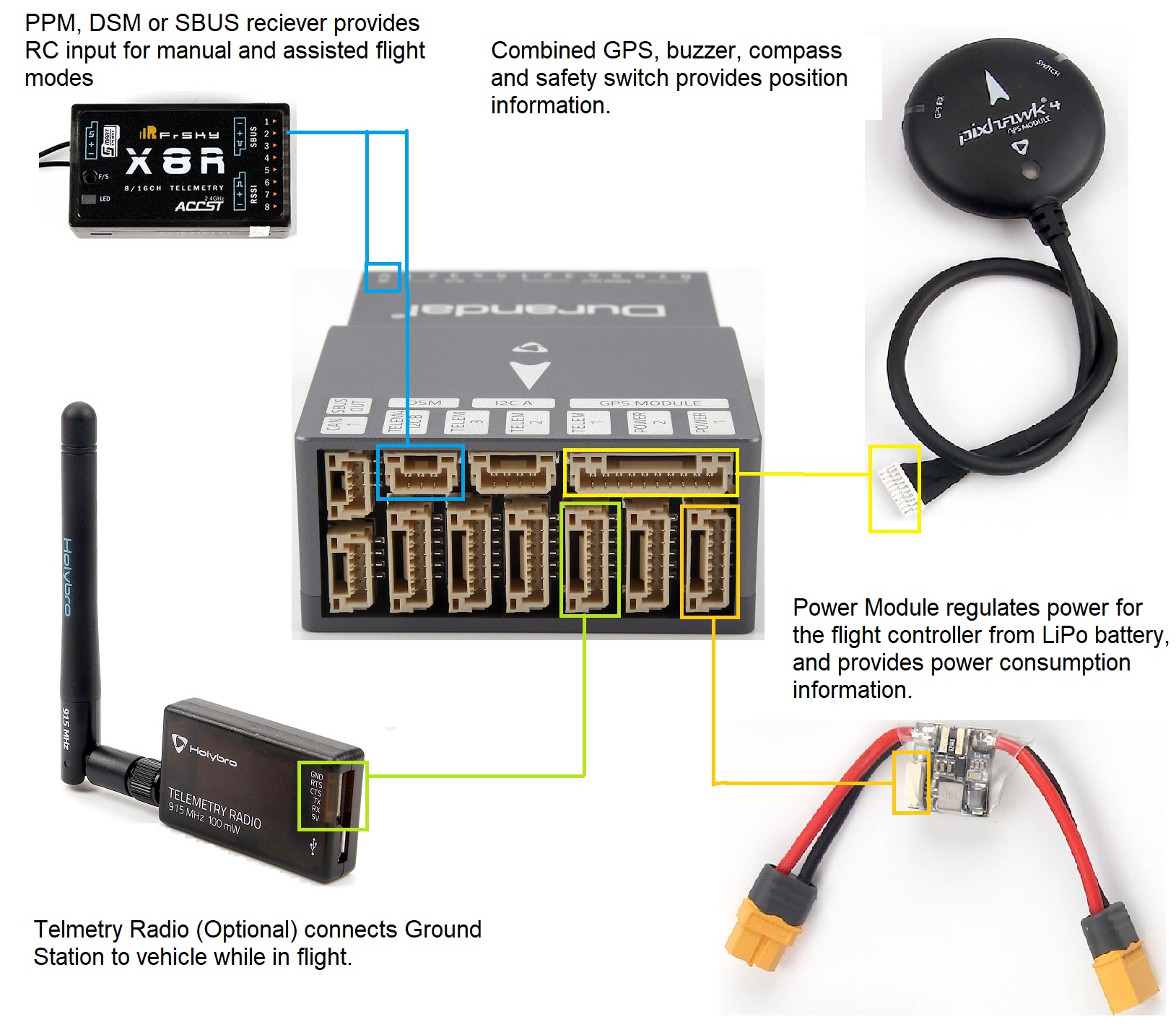

Wiring Chart Overview

The image below shows how to connect the most important sensors and peripherals (except the motor and servo outputs). We’ll go through each of these in detail in the following sections.

:::tip More information about available ports can be found here: Durandal > Pinouts. :::

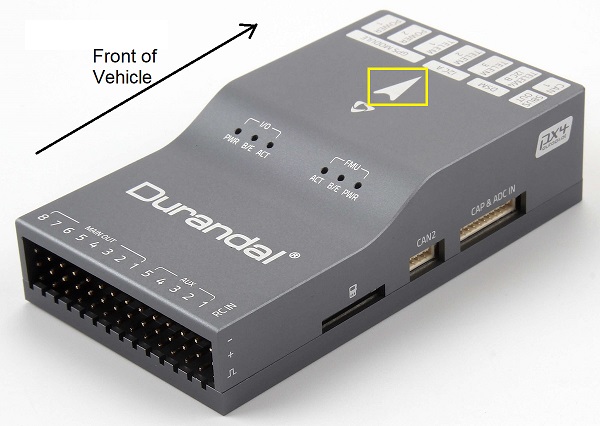

Mount and Orient Controller

Durandal should be mounted on the frame positioned as close to your vehicle’s center of gravity as possible, oriented top-side up with the arrow pointing towards the front of the vehicle.

If the controller cannot be mounted in the recommended/default orientation (e.g. due to space constraints) you will need to configure the autopilot software with the orientation that you actually used: Flight Controller Orientation.

:::tip The board has internal vibration-isolation. Do not use vibration-isolation foam to mount the controller (double sided tape is normally sufficient). :::

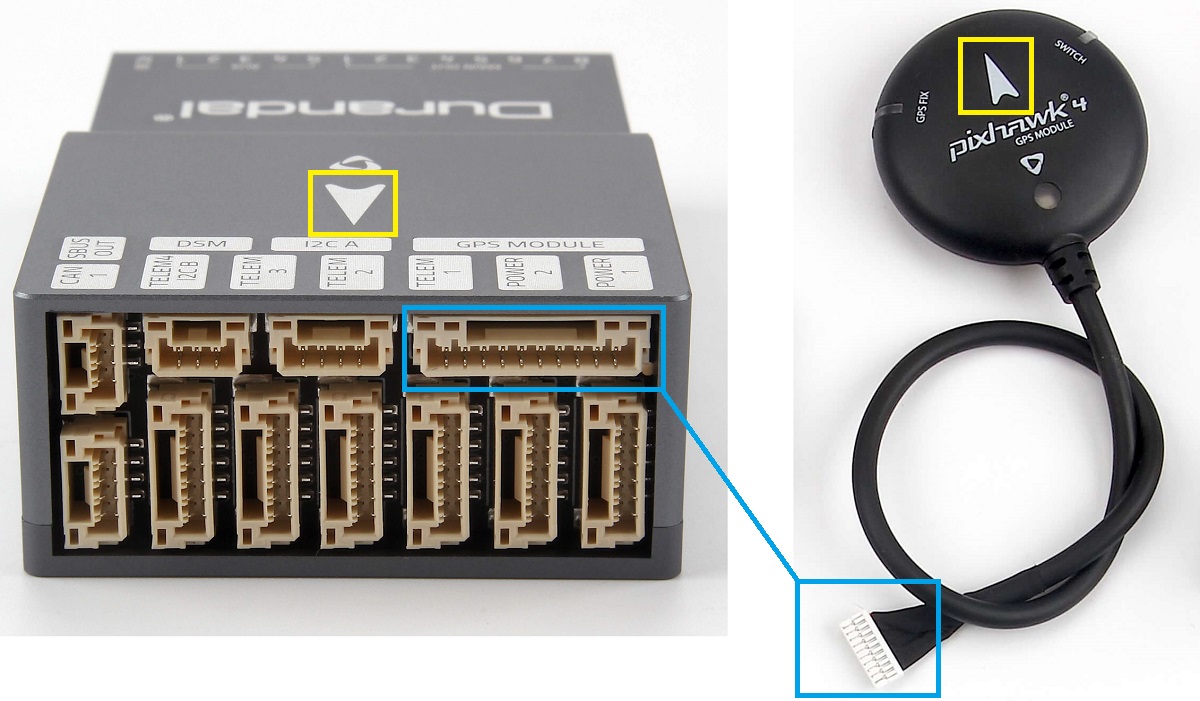

GPS + Compass + Buzzer + Safety Switch + LED

Durandal is designed to work well with the Pixhawk 4 GPS module, which has an integrated compass, safety switch, buzzer and LED. It connects directly to the GPS port using the 10 pin cable.

The GPS/Compass should be mounted on the frame as far away from other electronics as possible, with the direction marker towards the front of the vehicle (separating the compass from other electronics will reduce interference).

:::note The GPS module’s integrated safety switch is enabled by default (when enabled, PX4 will not let you arm the vehicle). To disable the safety press and hold the safety switch for 1 second. You can press the safety switch again to enable safety and disarm the vehicle (this can be useful if, for whatever reason, you are unable to disarm the vehicle from your remote control or ground station). :::

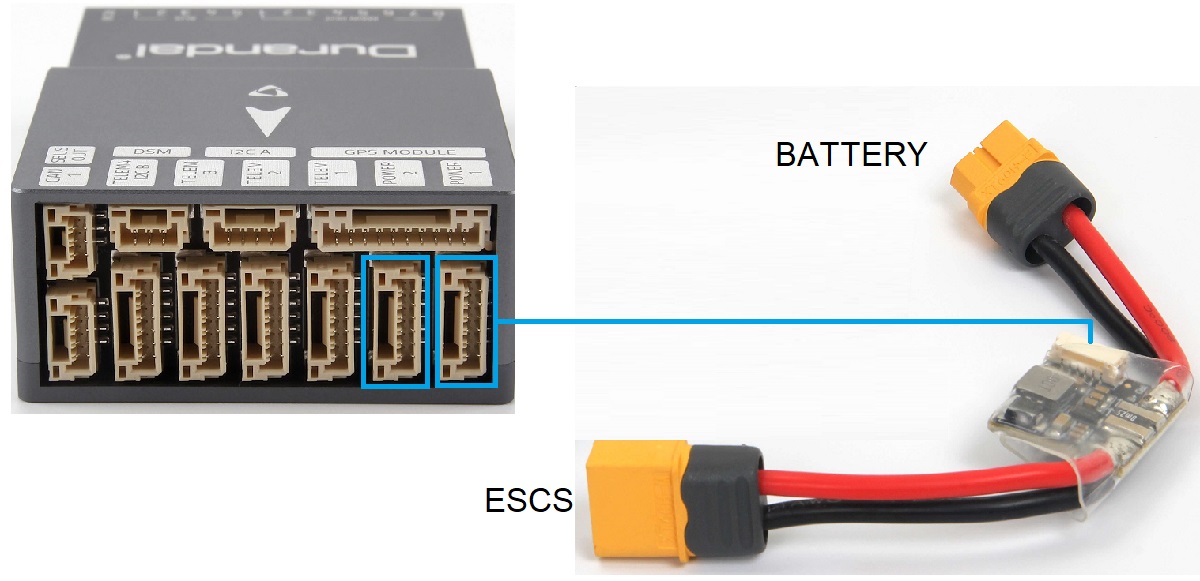

Power

You can use a power module or power distribution board to power motors/servos and measure power consumption. The recommended power modules are shown below.

PM02 v3 Power Module

The Power Module (PM02 v3) can be bundled with Durandal. It provides regulated power to flight controller and sends battery voltage/current to the flight controller.

Connect the output of the Power Module as shown.

- PM voltage/current port: connect to POWER1 port (or

POWER2) using the 6-wire GH cable supplied. - PM input (XT60 male connector): connect to the LiPo battery (2~12S).

- PM power output (XT60 female connector): wire out to any motor ESCs.

:::tip As this power module does not include power distribution wiring, you would normally just connect all the ESCs in parallel to the power module output (the ESC must be appropriate for the supplied voltage level). :::

:::tip The 8 pin power (+) rail of MAIN/AUX is not powered by the power module supply to the flight controller. If it will need to be separately powered in order to drive servos for rudders, elevons etc., the power rail needs to be connected to a BEC equipped ESC or a standalone 5V BEC or a 2S LiPo battery. Ensure the voltage of servo you are going to use is appropriate. :::

The power module has the following characteristics/limits:

- Max input voltage: 60V

- Max current sensing: 120A Voltage

- Current measurement configured for SV ADC Switching regulator outputs 5.2V and 3A max

- Weight: 20g

- Package includes:

- PM02 board

- 6pin MLX cable (1)

- 6pin GH cable (1)

:::note See also PM02v3 Power Module Manual (Holybro). :::

Pixhawk 4 Power Module (PM07)

The Pixhawk 4 Power Module (PM07) can be bundled/used with Durandal. It acts as both a power module and power distribution board, providing regulated power to flight controller and the ESCs, and sending battery voltage/current to the flight controller.

This is wired up in the same way as described in the Pixhawk 4 Quick Start > Power documentation.

It has the following characteristics/limits:

- PCB Current: total 120A outputs (MAX)

- UBEC 5V output current: 3A

- UBEC input voltage : 7~51v (2~12s LiPo)

- Dimensions: 68508 mm

- Mounting Holes: 45*45mm

- Weight: 36g

- Package includes:

- PM07 board (1)

- 80mm XT60 connector wire (1)

:::note See also PM07 Quick Start Guide (Holybro). :::

Battery Configuration

The battery/power setup must be configured in Power Settings. For either Power Module you will need to configure the Number of Cells.

You will not need to update the voltage divider unless you are using some other power module (e.g. the one from the Pixracer).

Radio Control

A remote control (RC) radio system is required if you want to manually control your vehicle (PX4 does not require a radio system for autonomous flight modes).

You will need to select a compatible transmitter/receiver and then bind them so that they communicate (read the instructions that come with your specific transmitter/receiver).

The instructions below show how to connect the different types of receivers to Durandal:

-

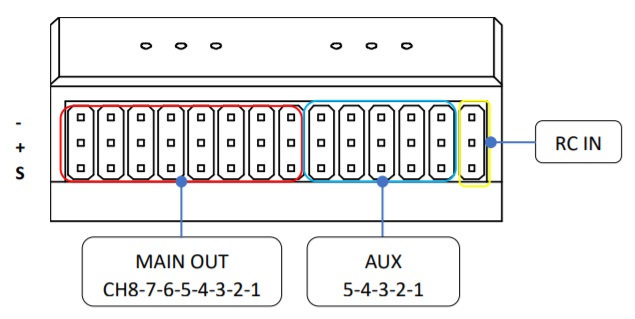

Spektrum/DSM receivers connect to the DSM RC input.

-

PPM and S.Bus receivers connect to the SBUS_IN/PPM_IN input port (marked as RC IN, next to the MAIN/AUX inputs).

-

PPM and PWM receivers that have an individual wire for each channel must connect to the PPM RC port via a PPM encoder like this one (PPM-Sum receivers use a single signal wire for all channels).

For more information about selecting a radio system, receiver compatibility, and binding your transmitter/receiver pair, see: Remote Control Transmitters & Receivers.

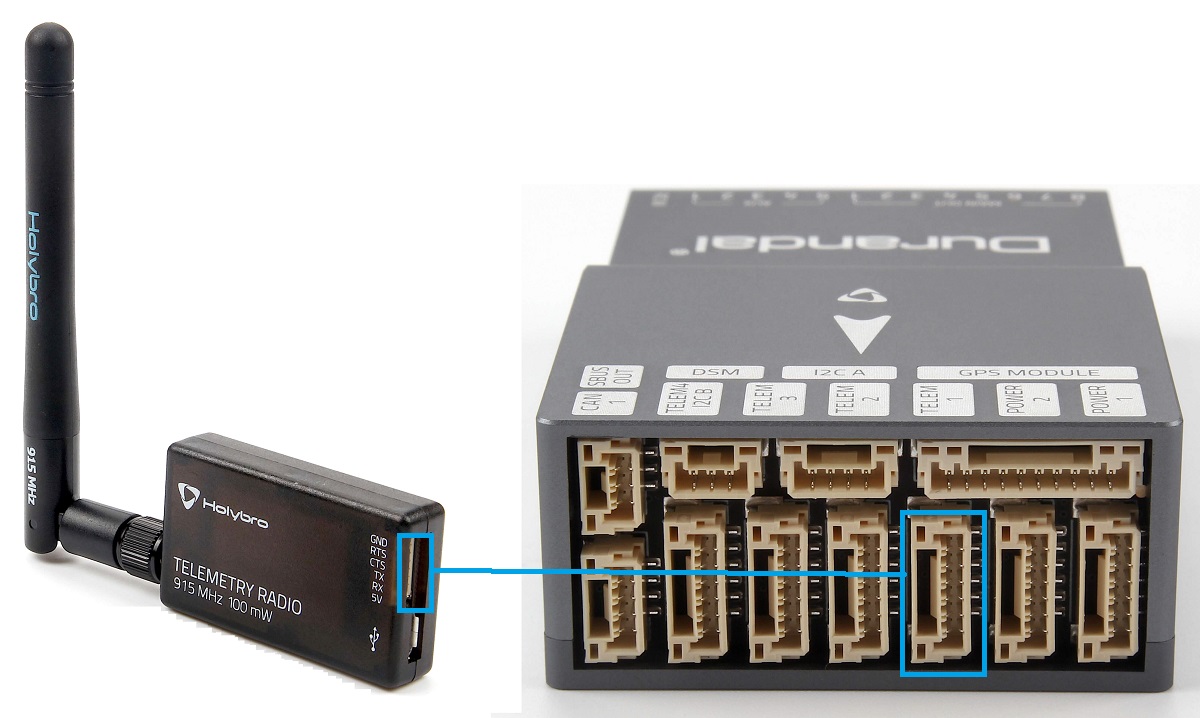

Telemetry Radios (Optional)

Telemetry radios may be used to communicate and control a vehicle in flight from a ground station (for example, you can direct the UAV to a particular position, or upload a new mission).

The vehicle-based radio should be connected to the TELEM1 port as shown below using one of the 6-pos connectors (if connected to this port, no further configuration is required). The other radio is connected to your ground station computer or mobile device (usually by USB).

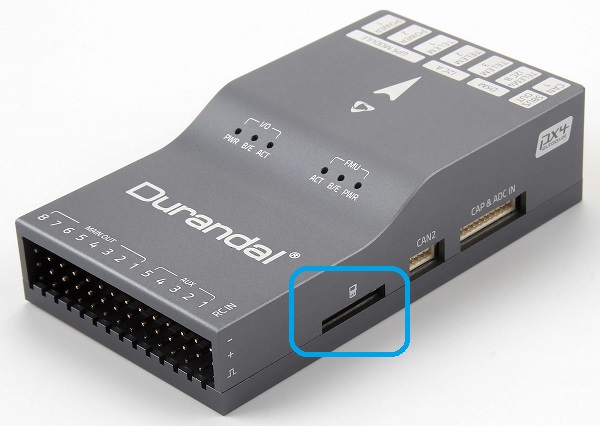

SD Card (Optional)

SD cards are highly recommended as they are needed to log and analyse flight details, to run missions, and to use UAVCAN-bus hardware. Insert an SD card into the Durandal where indicated below.

:::tip For more information see Basic Concepts > SD Cards (Removable Memory). :::

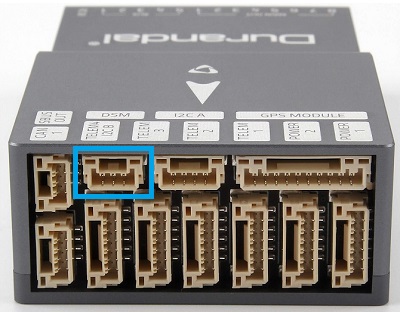

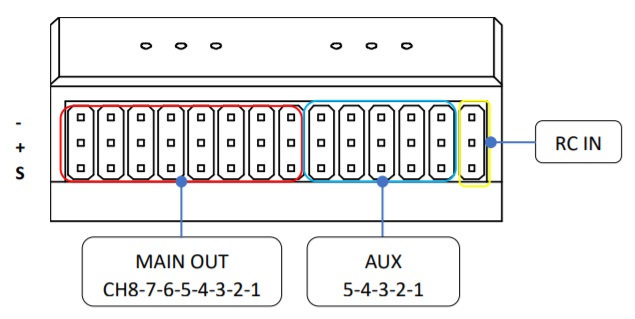

Motors

Motors/servos control signals are connected to the I/O PWM OUT (MAIN OUT) and FMU PWM OUT (AUX) ports in the order specified for your vehicle in the Airframe Reference.

The motors must be separately powered.

:::note If your frame is not listed in the airframe reference then use a “generic” airframe of the correct type. :::

:::tip Durandal has 5 AUX ports, so cannot be used with airframes that map AUX6, AUX7, AUX8 to motors or other critical flight controls. :::

Other Peripherals

The wiring and configuration of optional/less common components is covered within the topics for individual peripherals.

Pinouts

PX4 Configuration

First you will need to install PX4 “Master” Firmware onto the controller using QGroundControl.

:::note Durandal support will be in the stable PX4 release that follows PX4 v1.10. :::

Further general configuration information is covered in: Autopilot Configuration.

QuadPlane specific configuration is covered here: QuadPlane VTOL Configuration

Further information

- Durandal Overview

- Durandal Technical Data Sheet (Holybro)

- Durandal Pinouts (Holybro)

- Durandal_MB_H743sch.pdf (Durandal Schematics)

- STM32H743IIK_pinout.pdf (Durandal Pinmap)

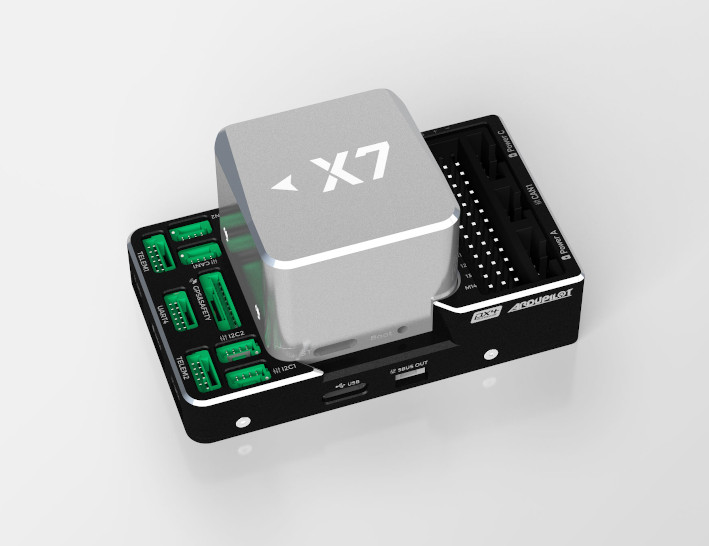

quick start cube - APM, Mission-planner

Cube Wiring Quick Start

:::warning PX4 does not manufacture this (or any) autopilot. Contact the manufacturer for hardware support or compliance issues.

Note also that while Cube Black is fully supported by PX4, support for Cube Yellow and Cube Orange is Experimental. :::

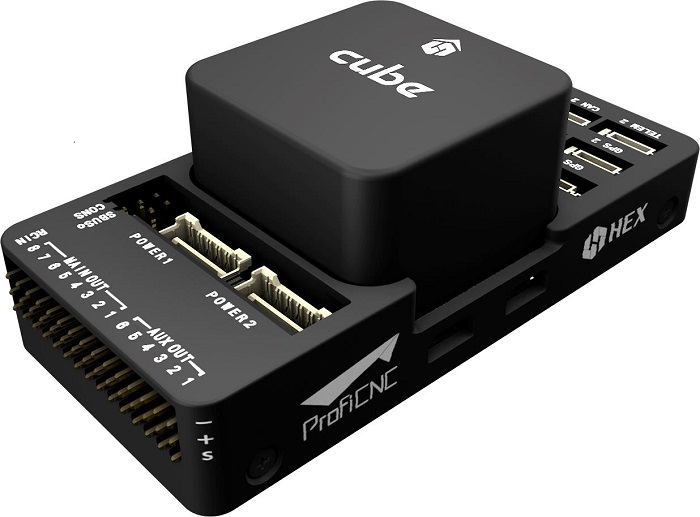

This quick start guide shows how to power the Cube® flight controllers and connect their most important peripherals.

:::tip The instructions apply to all Cube variants, including Cube Black, Cube Yellow and Cube Orange. Further/updated information may be available in the Cube User Manual (Cube Docs). :::

Accessories

Cube comes with most (or all) of the accessories you will need when purchased.

The exception is that some kits do not include a GPS, which will have to be purchased separately (see below).

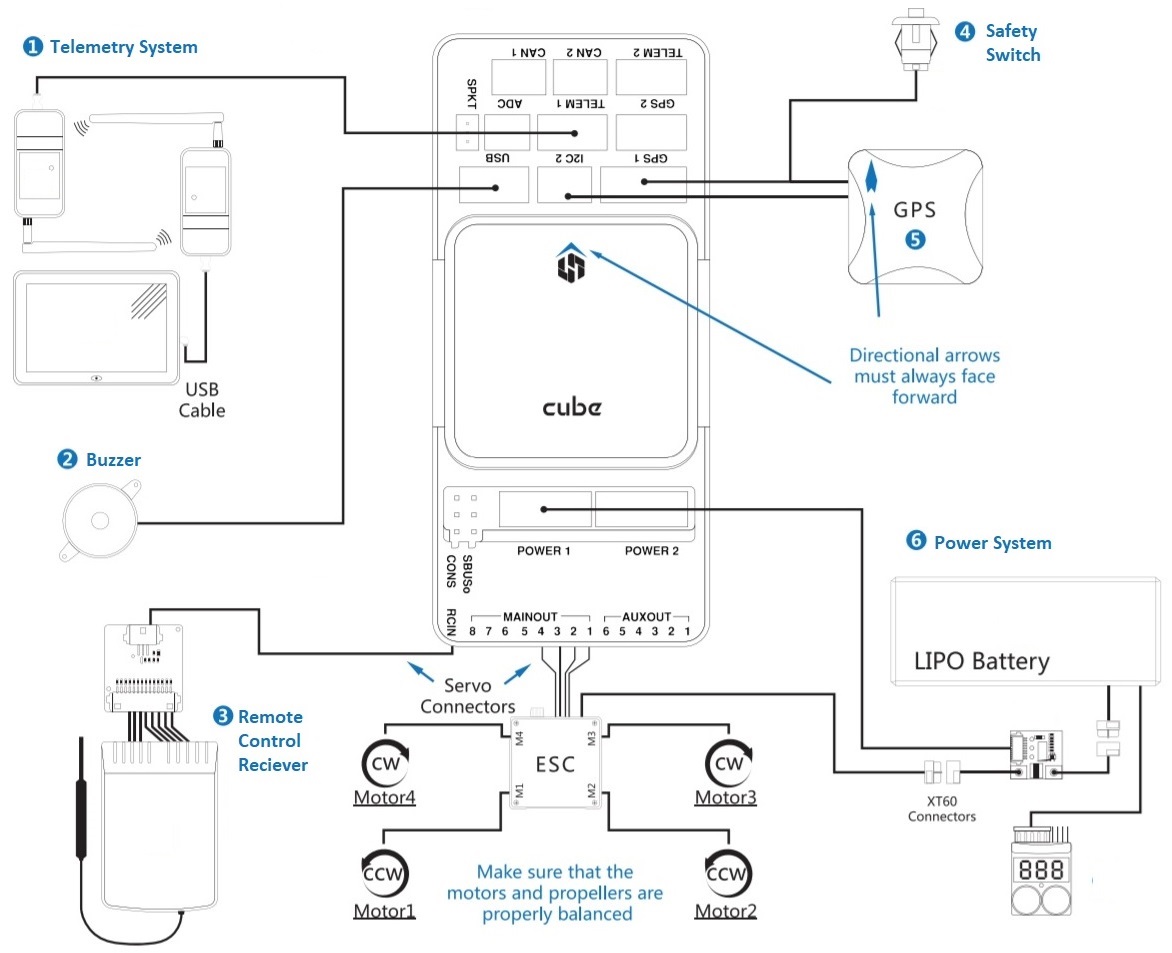

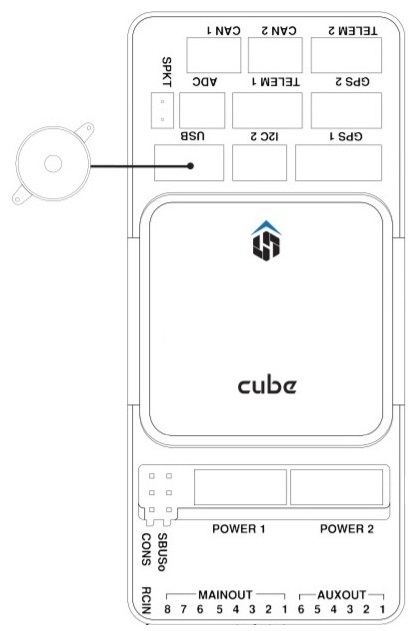

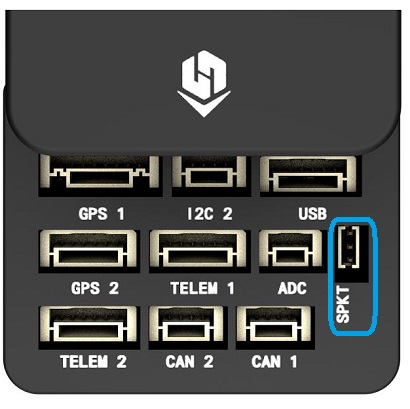

Wiring Overview

The image below shows how to connect the most important sensors and peripherals. We’ll go through each of these in detail in the following sections.

- Telemetry System — Allows you to plan/run missions, and control and monitor the vehicle in real time. Typically includes telemetry radios, tablet/PC and ground station software.

- Buzzer — Provides audio signals that indicate what the UAV is doing

- Remote Control Receiver System — Connects to a hand-held transmitter that an operator can use to manually fly the vehicle (shown is a PWM receiver with PWM->PPM converter).

- (Dedicated) Safety switch — Press and hold to lock and unlock motors. Only required if you are not using the recommended GPS with inbuilt safety switch.

- GPS, Compass, LED, Safety Switch — The recommended GPS module contains GPS, Compass, LED and Safety Switch.

- Power System — Powers Cube and the motor ESCs. Consists of LiPo battery, power module, and optional battery warning system (audio warning if battery power goes below a predefined level).

:::note

The port labeled GPS2 maps to TEL4 in PX4 (i.e. if connecting to the port labeled GPS2, assign the serial port configuration parameter for the connected hardware to TEL4).

:::

:::tip More information about available ports can be found here: Cube > Ports. :::

Mount and Orient Controller

Mount the Cube as close as possible to your vehicle’s center of gravity, ideally oriented top-side up and with the arrow pointing towards the front of the vehicle (note the subtle arrow marker on top of the cube)

:::note If the controller cannot be mounted in the recommended/default orientation (e.g. due to space constraints) you will need to configure the autopilot software with the orientation that you actually used: Flight Controller Orientation. :::

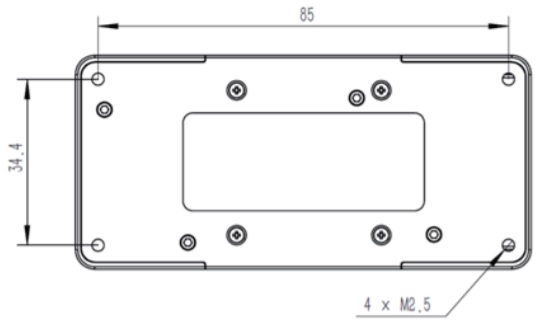

The Cube can be mounted using either vibration-damping foam pads (included in the kit) or mounting screws. The mounting screws in the Cube accessories are designed for a 1.8mm thick frameboard. Customized screws are supposed to be M2.5 with thread length inside Cube in range 6mm~7.55mm.

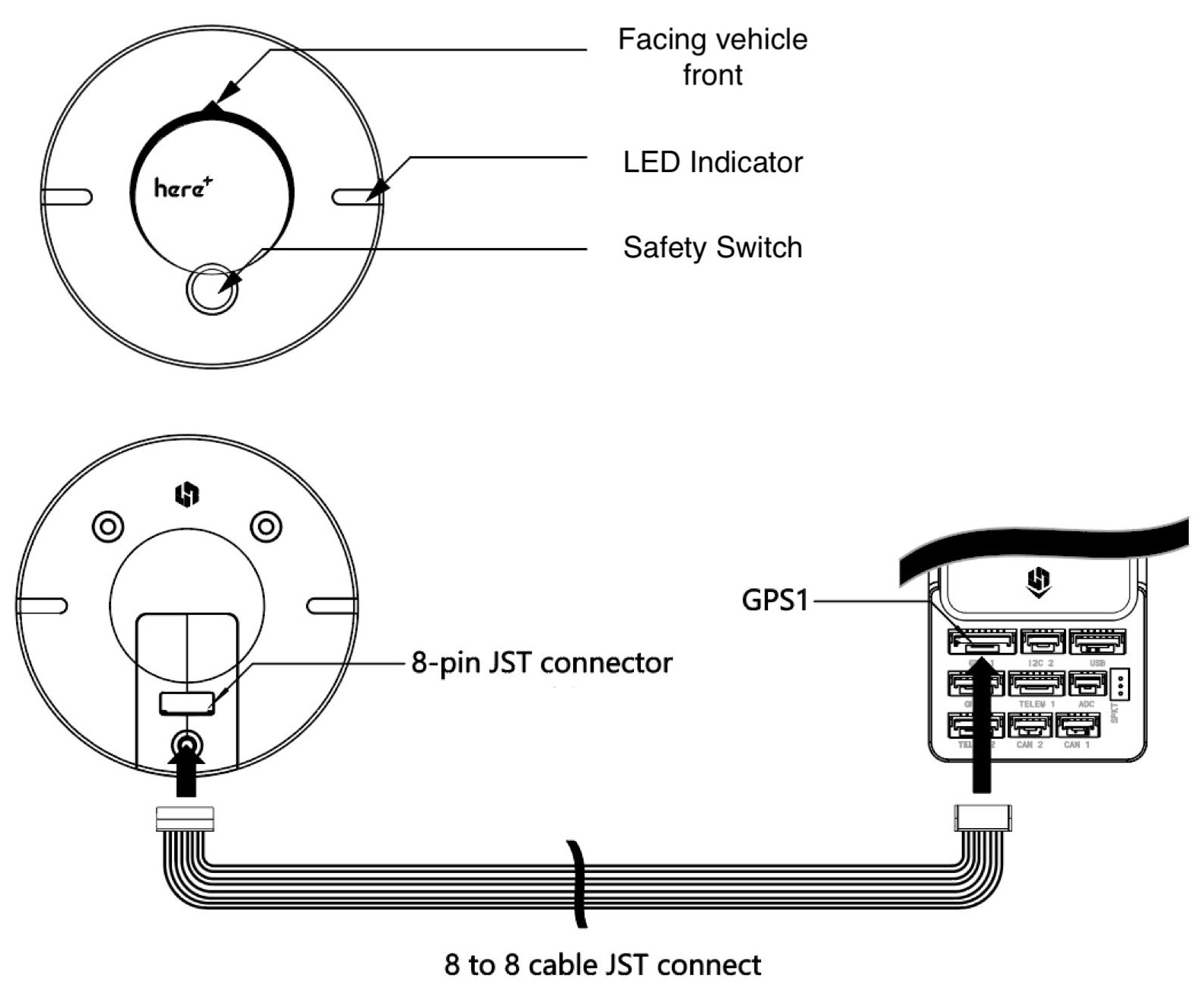

GPS + Compass + Safety Switch + LED

The recommended GPS modules are the Here and Here+, both of which incorporate a GPS module, Compass, Safety Switch and LEDs. The difference between the modules is that Here+ supports centimeter level positioning via RTK. Otherwise they are used/connected in the same way.

:::warning The Here+ has been superseded by the Here3 a UAVCAN RTK-GNSS that incorporate a compass and LEDs (but no safety switch). See UAVCAN for documentation on how it should be connected. :::

The module should be mounted on the frame as far away from other electronics as possible, with the direction marker towards the front of the vehicle (separating the compass from other electronics will reduce interference). It must be connected to the GPS1 port using the supplied 8-pin cable.

The diagram below shows a schematic view of the module and its connections.

:::note The GPS module’s integrated safety switch is enabled by default (when enabled, PX4 will not let you arm the vehicle). To disable the safety press and hold the safety switch for 1 second. You can press the safety switch again to enable safety and disarm the vehicle (this can be useful if, for whatever reason, you are unable to disarm the vehicle from your remote control or ground station). :::

:::tip If you want to use an old-style 6-pin GPS module, the kit comes with a cable that you can use to connect both the GPS and Safety Switch. :::

Safety Switch

The dedicated safety switch that comes with the Cube is only required if you are not using the recommended GPS (which has an inbuilt safety switch).

If you are flying without the GPS you must attach the switch directly to the GPS1 port in order to be able to arm the vehicle and fly (or via a supplied cable if using an old-style 6-pin GPS).

Buzzer

The buzzer plays tones and tunes that provide audible notification of vehicle status (including tones that are helpful for debugging startup issues, and that notify of conditions that might affect safe operation of the vehicle).

The buzzer should be connected to the USB port as shown (no further configuration is required).

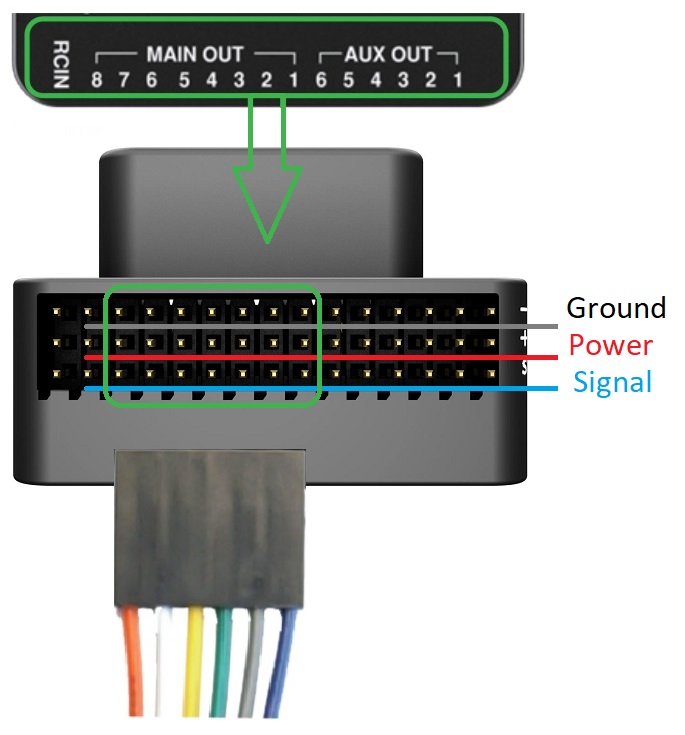

Radio Control

A remote control (RC) radio system is required if you want to manually control your vehicle (PX4 does not require a radio system for autonomous flight modes).

You will need to select a compatible transmitter/receiver and then bind them so that they communicate (read the instructions that come with your specific transmitter/receiver).

The instructions below show how to connect the different types of receivers.

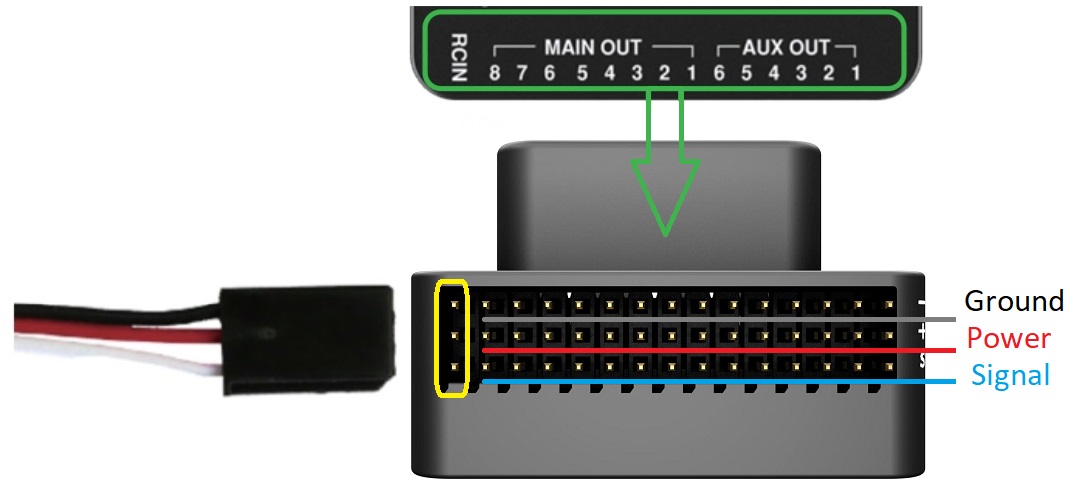

PPM-SUM / Futaba S.Bus receivers

Connect the ground(-),power(+),and signal(S) wires to the RC pins using the provided 3-wire servo cable.

Spektrum Satellite Receivers

Spektrum DSM, DSM2, and DSM-X Satellite RC receivers connect to the SPKT/DSM port.

PWM Receivers

The Cube cannot directly connect to PPM or PWM receivers that have an individual wire for each channel. PWM receivers must therefore connect to the RCIN port via a PPM encoder module, which may be purchased from hex.aero or proficnc.com.

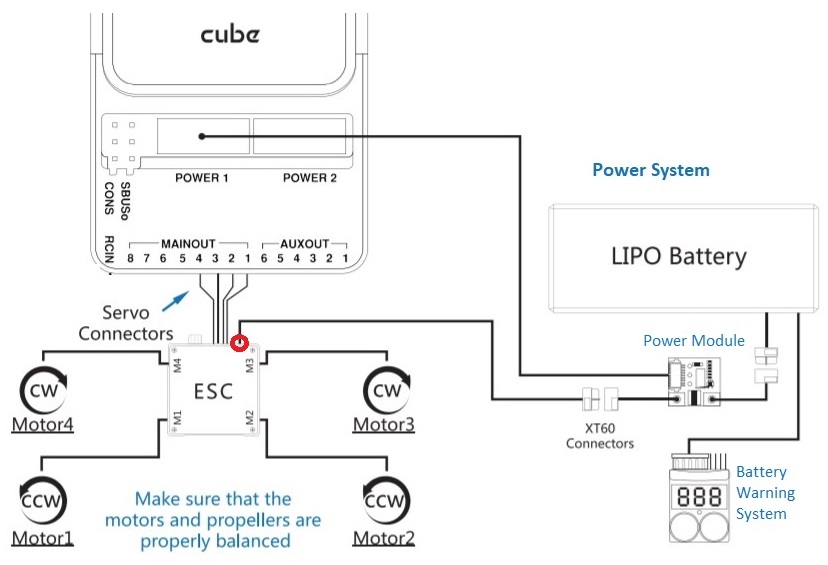

Power

Cube is typically powered from a Lithium Ion Polymer (LiPo) Battery via a Power Module (supplied with the kit) that is connected to the POWER1 port. The power module provides reliable supply and voltage/current indication to the board, and may separately supply power to ESCs that are used to drive motors on a multicopter vehicle.

A typical power setup for a Multicopter vehicle is shown below.

:::Note The power (+) rail of MAIN/AUX is not powered by the power module supply to the flight controller. In order to drive servos for rudders, elevons, etc., it will need to be separately powered.

This can be done by connecting the power rail to a BEC equipped ESC, a standalone 5V BEC, or a 2S LiPo battery. Ensure the voltage of servo you are going to use is appropriate! :::

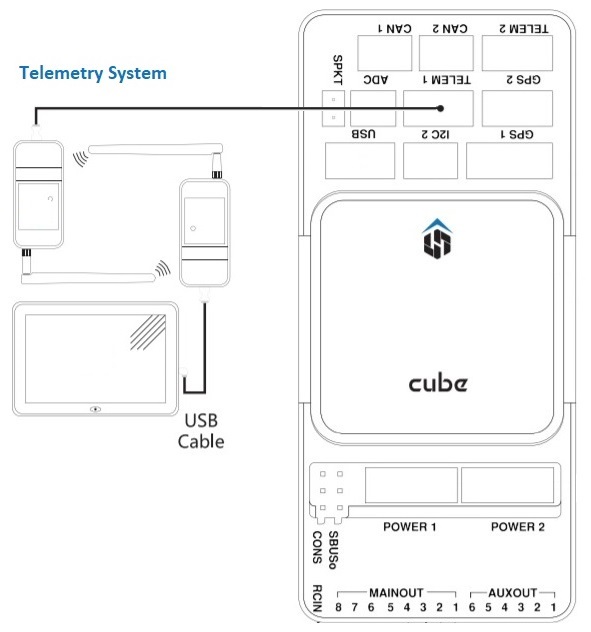

Telemetry System (Optional)

A telemetry system allows you to communicate with, monitor, and control a vehicle in flight from a ground station (for example, you can direct the UAV to a particular position, or upload a new mission).

The communication channel is via Telemetry Radios. The vehicle-based radio should be connected to the TELEM1 port (if connected to this port, no further configuration is required). The other radio is connected to your ground station computer or mobile device (usually via USB).

SD Card (Optional)

SD cards are highly recommended as they are needed to log and analyse flight details, to run missions, and to use UAVCAN-bus hardware. Insert the Micro-SD card into Cube as shown (if not already present).

:::tip For more information see Basic Concepts > SD Cards (Removable Memory). :::

Motors

Motors/servos are connected to the MAIN and AUX ports in the order specified for your vehicle in the Airframe Reference.

:::note This reference lists the output port to motor/servo mapping for all supported air and ground frames (if your frame is not listed in the reference then use a “generic” airframe of the correct type). :::

:::caution The mapping is not consistent across frames (e.g. you can’t rely on the throttle being on the same output for all plane frames). Make sure to use the correct mapping for your vehicle. :::

Other Peripherals

The wiring and configuration of optional/less common components is covered within the topics for individual peripherals.

:::note

If connecting peripherals to the port labeled GPS2, assign the PX4 serial port configuration parameter for the hardware to TEL4 (not GPS2).

:::

Configuration

Configuration is performed using QGroundContro.

After downloading, installing and running QGroundControl, connect the board to your computer as shown.

Basic/common configuration information is covered in: Autopilot Configuration.

QuadPlane specific configuration is covered here: QuadPlane VTOL Configuration

Bootloader Updates

If you get the [Program PX4IO(../getting_started/tunes.md#program-px4io) warning tone after flashing PX4 firmware, you may need to update the bootloader.

The safety switch can be used to force bootloader updates. To use this feature de-power the Cube, hold down the safety switch, then power the Cube over USB.

Further information

- Cube Black

- Cube Yellow

- Cube Orange

- Cube Docs (Manufacturer):

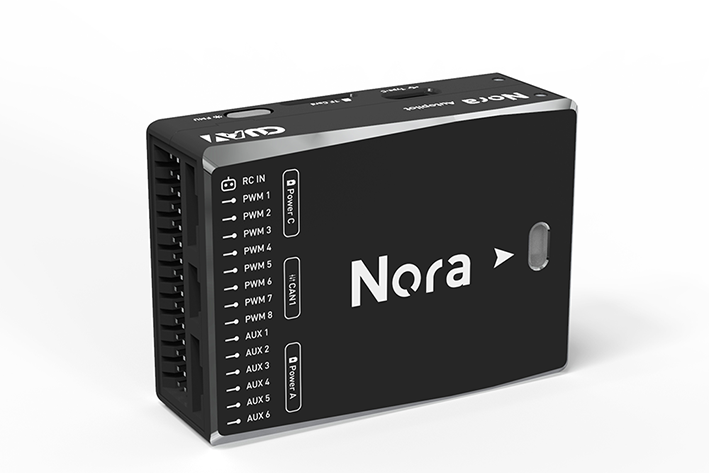

quick start cuav v5 plus - APM, Mission-planner

CUAV V5+ Wiring Quick Start

:::warning PX4 does not manufacture this (or any) autopilot. Contact the manufacturer for hardware support or compliance issues. :::

This quick start guide shows how to power the CUAV V5+ flight controller and connect its most important peripherals.

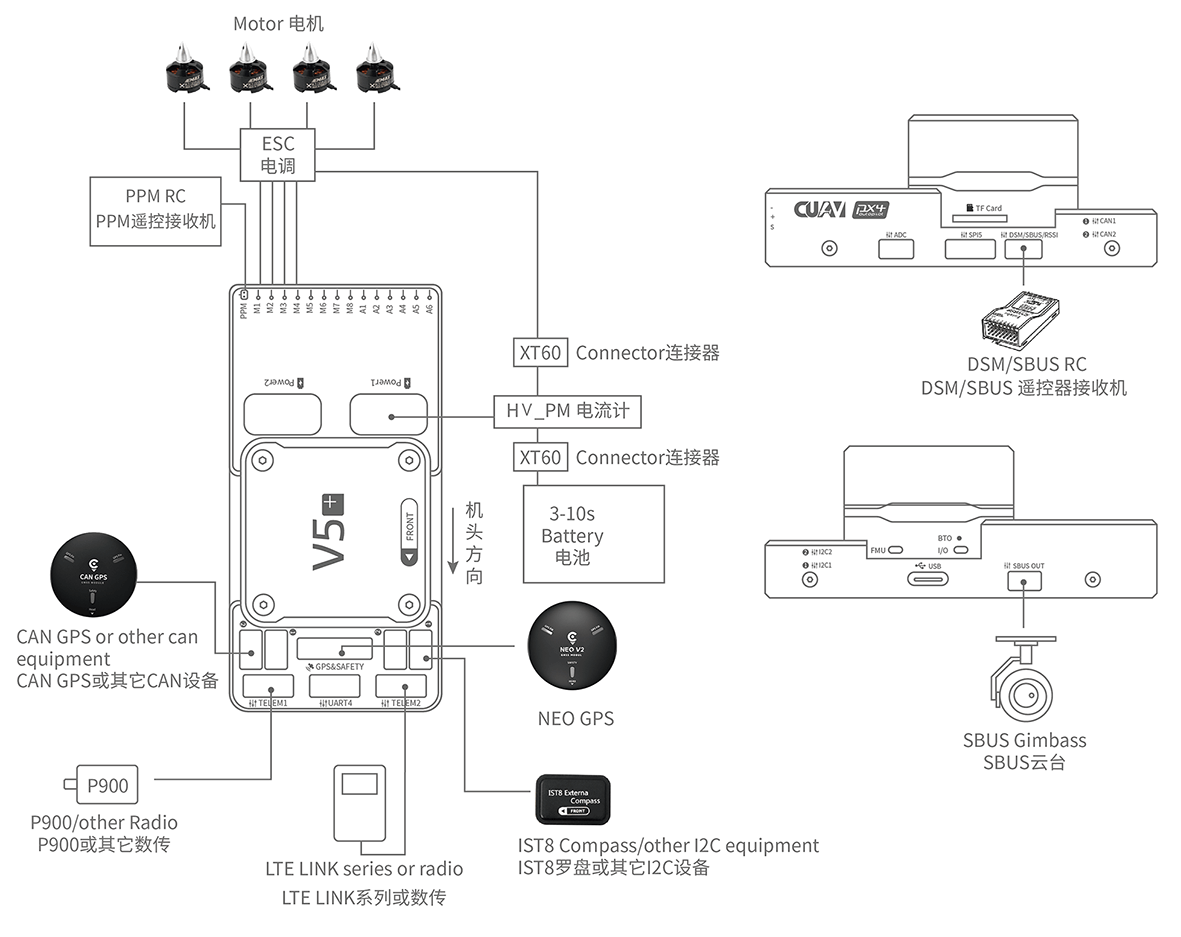

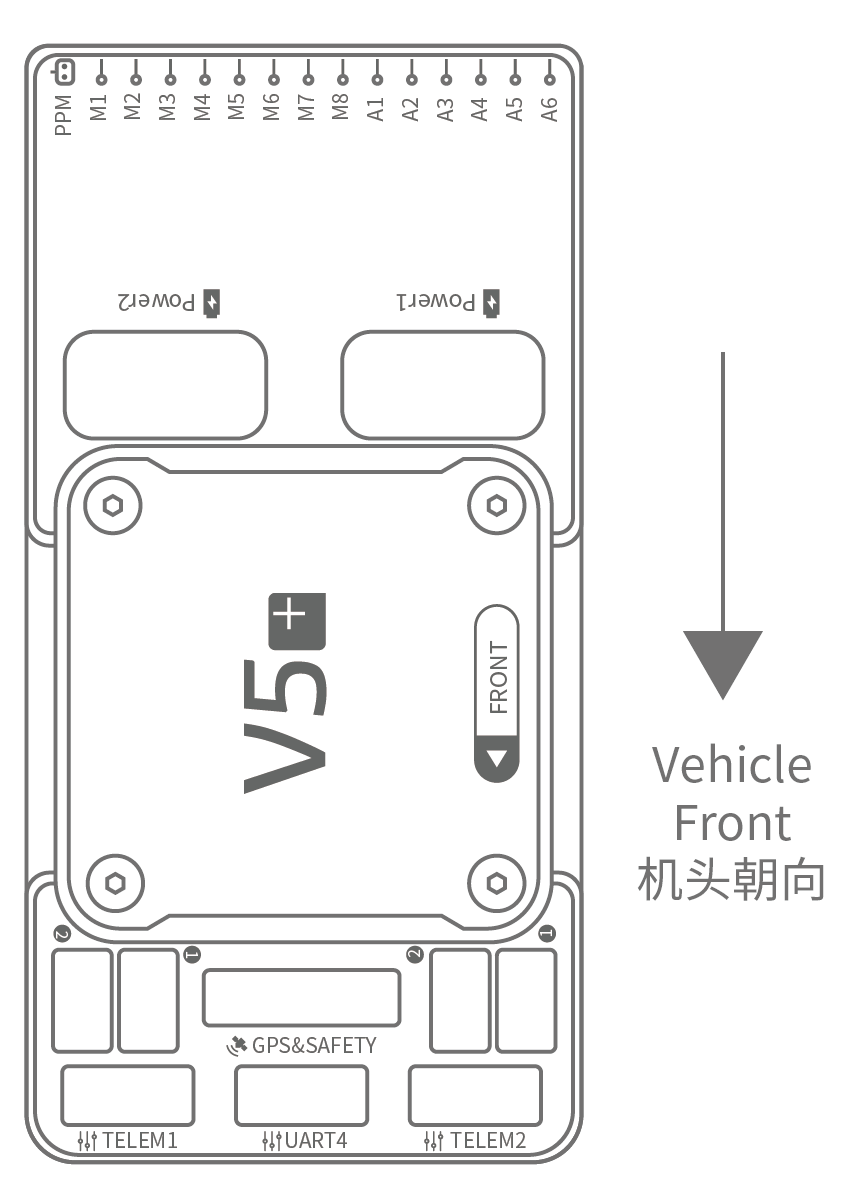

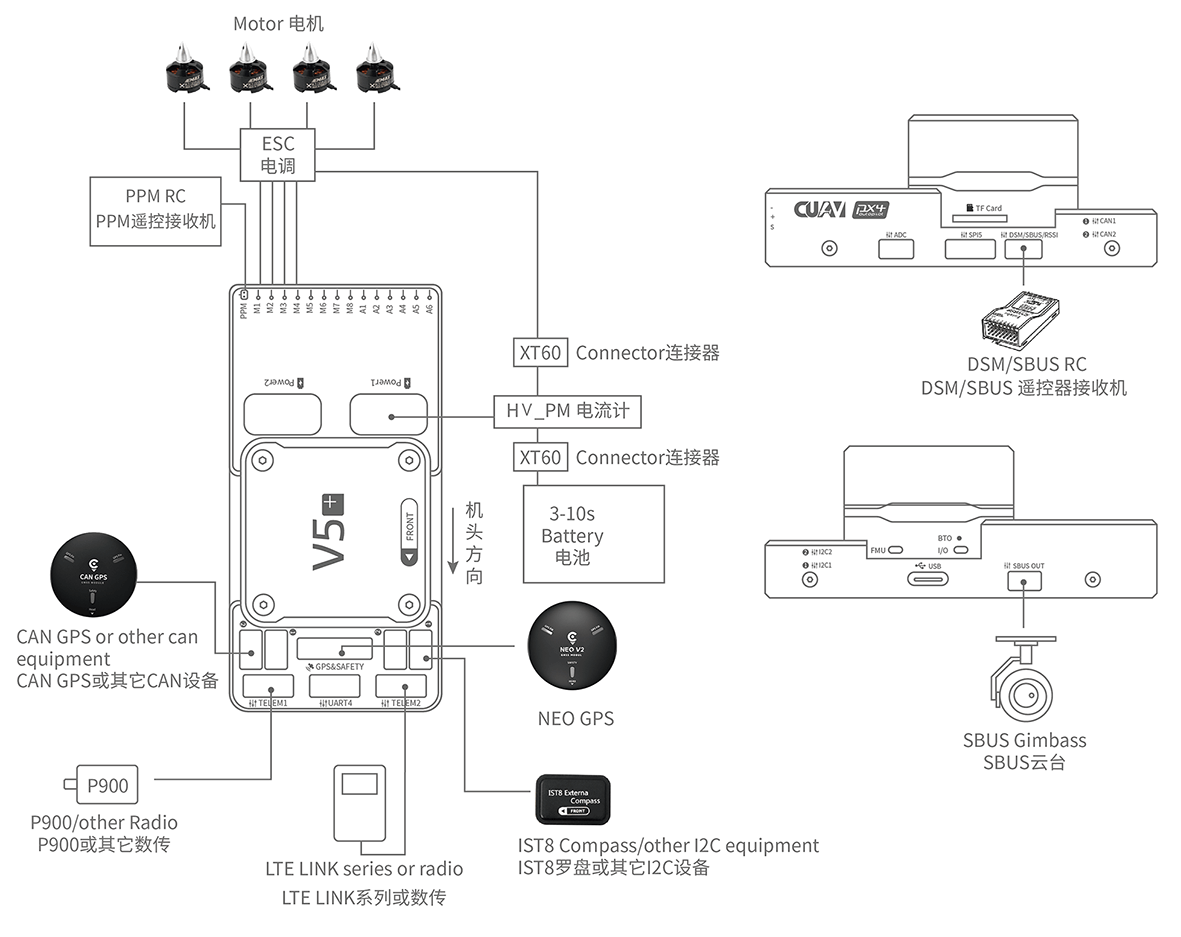

Wiring Chart Overview

The image below shows how to connect the most important sensors and peripherals (except the motor and servo outputs). We’ll go through each of these in detail in the following sections.

| Main interface | Function |

|---|---|

| Power1 | Connect power module. Power input with analog voltage and current detection. Do not use a Digital PM on this connector! |

| Power2 | Connect i2c smart battery. |

| TF CARD | SD card for log storage (card pre-inserted in factory). |

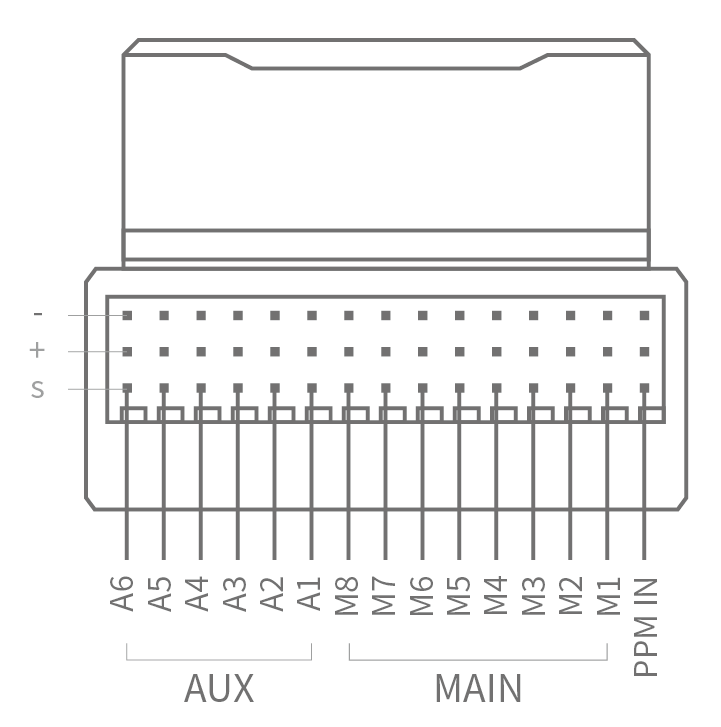

| M1~M8 | PWM outputs. Can be used to control motors or servos. |

| A1~A6 | PWM outputs. Can be used to control motors or servos. |

| DSU7 | Used for FMU debug, reading debug information. |

| I2C1/I2C2 | Connect an I2C device such as an external compass. |

| CAN1/CAN2 | Connect UAVCAN devices such as CAN GPS. |

| TYPE-C(USB) | Connect to a computer for communication between the flight controller and the computer, such as loading firmware. |

| SBUS OUT | Connect SBUS devices (e.g. camera gimbals). |

| GPS&SAFETY | Connect to Neo GPS, which includes GPS, safety switch, buzzer interface. |

| TELEM1/TELEM2 | Connect to the Telemetry System. |

| DSM/SBUS/RSSI | Includes DSM, SBUS, RSSI signal input interface, DSM interface can be connected to DSM satellite receiver, SBUS interface to SBUS remote control receiver, RSSI for signal strength return module. |

:::note For more interface information, please read V5+ Manual. :::

:::note If the controller cannot be mounted in the recommended/default orientation (e.g. due to space constraints) you will need to configure the autopilot software with the orientation that you actually used: Flight Controller Orientation. :::

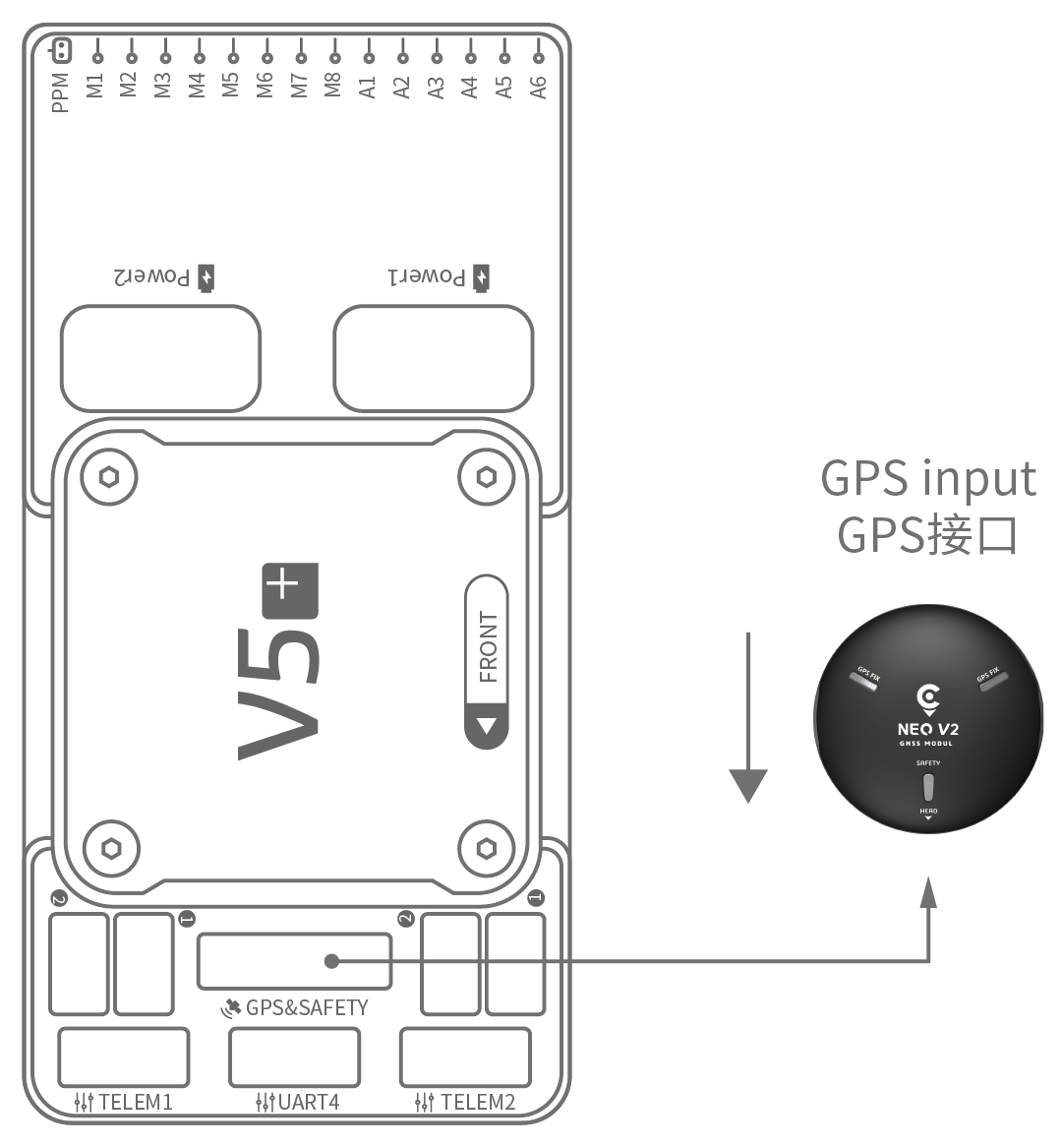

GPS + Compass + Safety Switch + LED

The recommended GPS module is the Neo v2 GPS, which contains GPS, compass, safety switch, buzzer, LED status light.

:::note Other GPS modules may not work (see this compatibility issue)). :::

The GPS/Compass module should be mounted on the frame as far away from other electronics as possible, with the direction marker towards the front of the vehicle (Neo v2 GPS arrow is in the same direction as the flight control arrow). Connect to the flight control GPS interface using a cable.

:::note If you use the NEO V2 PRO GNSS (CAN GPS), please use the cable to connect to the flight control CAN interface. :::

Safety Switch

The dedicated safety switch that comes with the V5+ is only required if you are not using the recommended Neo V2 GPS (which has an inbuilt safety switch).

If you are flying without the GPS you must attach the switch directly to the GPS1 port in order to be able to arm the vehicle and fly (if you use the old 6-pin GPS, please read the definition of the bottom interface to change the line).

Buzzer

If you do not use the recommended GPS, the buzzer may not work.

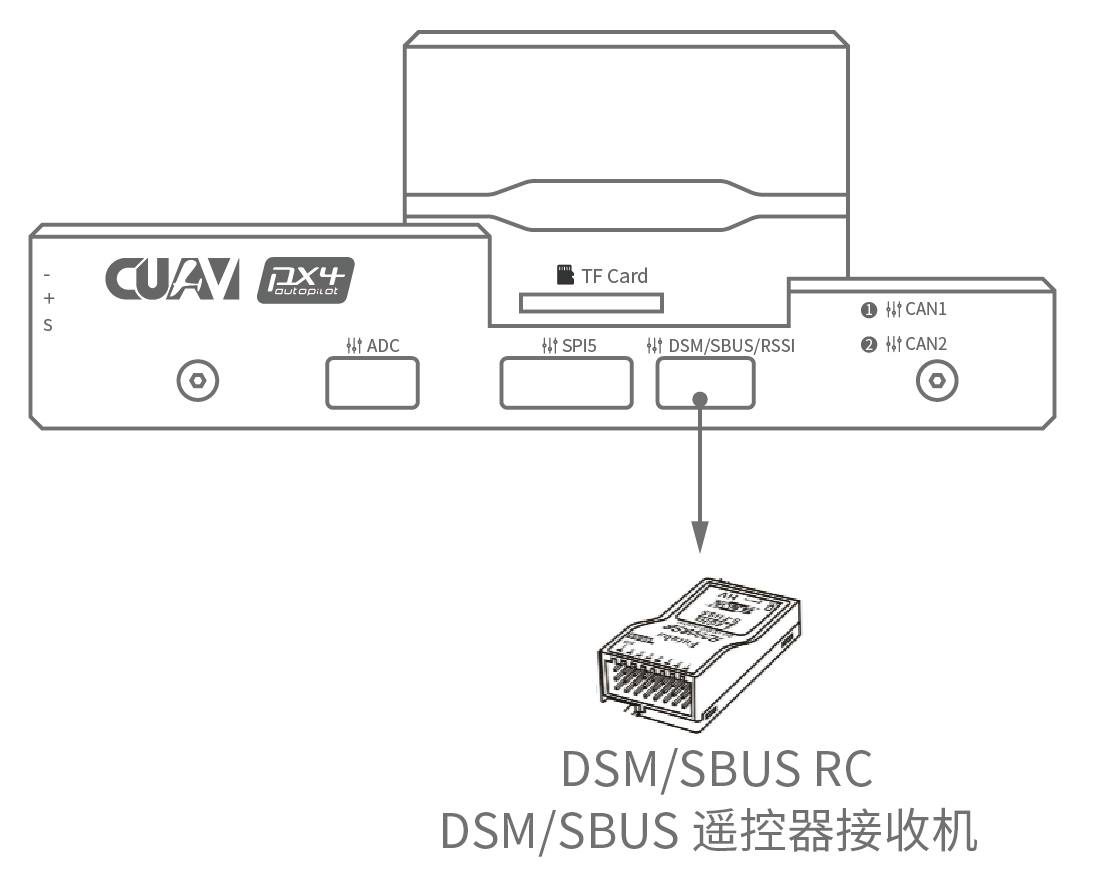

Radio Control

A remote control (RC) radio system is required if you want to manually control your vehicle (PX4 does not require a radio system for autonomous flight modes). You will need to select a compatible transmitter/receiver and then bind them so that they communicate (read the instructions that come with your specific transmitter/receiver).

The figure below shows how you can access your remote receiver (please find the SBUS cable in the kit).

Spektrum Satellite Receivers

The V5+ has a dedicated DSM cable. If using a Spektrum satellite receiver, this should be connected to the flight controller DSM/SBUS/RSSI interface.

Power

The V5+ kit includes the HV_PM module, which supports 2~14S LiPo batteries.

Connect the 6pin connector of the HW_PM module to the flight control Power1 interface.

:::warning The supplied power module is unfused. Power must be turned off while connecting peripherals. :::

:::note The power module is not a power source for peripherals connected to the PWM outputs. If you’re connecting servos/actuators you will need to separately power them using a BEC. :::

Telemetry System (Optional)

A telemetry system allows you to communicate with, monitor, and control a vehicle in flight from a ground station (for example, you can direct the UAV to a particular position, or upload a new mission).

The communication channel is via Telemetry Radios.

The vehicle-based radio should be connected to either the TELEM1 or TELEM2 port (if connected to these ports, no further configuration is required).

The other radio is connected to your ground station computer or mobile device (usually via USB).

SD Card (Optional)

An SD card is inserted in the factory (you do not need to do anything).

Motors

Motors/servos are connected to the MAIN and AUX ports in the order specified for your vehicle in the Airframes Reference.

Pinouts

Download V5+ pinouts from here.

Further Information

- Airframe build-log using CUAV v5+ on a DJI FlameWheel450

- CUAV V5+ Manual (CUAV)

- CUAV V5+ docs (CUAV)

- FMUv5 reference design pinout (CUAV)

- CUAV Github (CUAV)

- Base board design reference (CUAV)

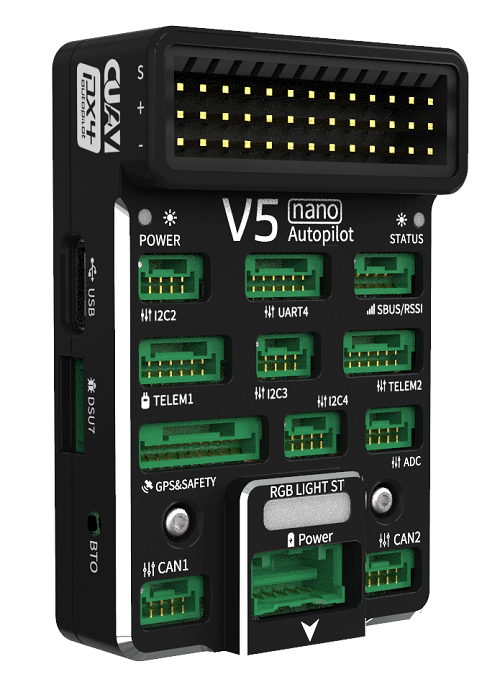

quick start cuav v5 nano - APM, Mission-planner

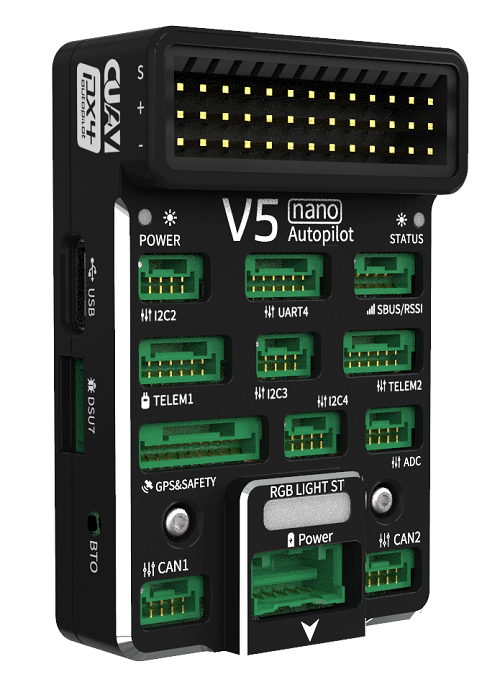

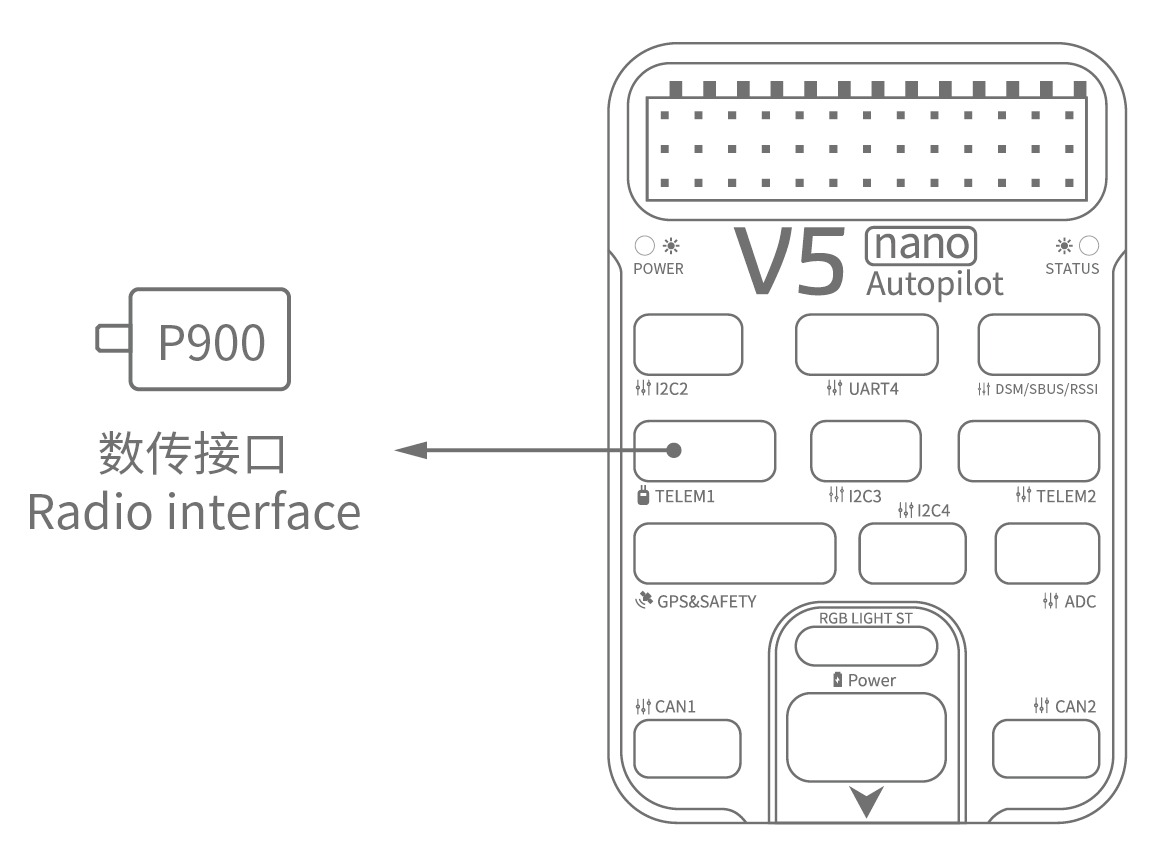

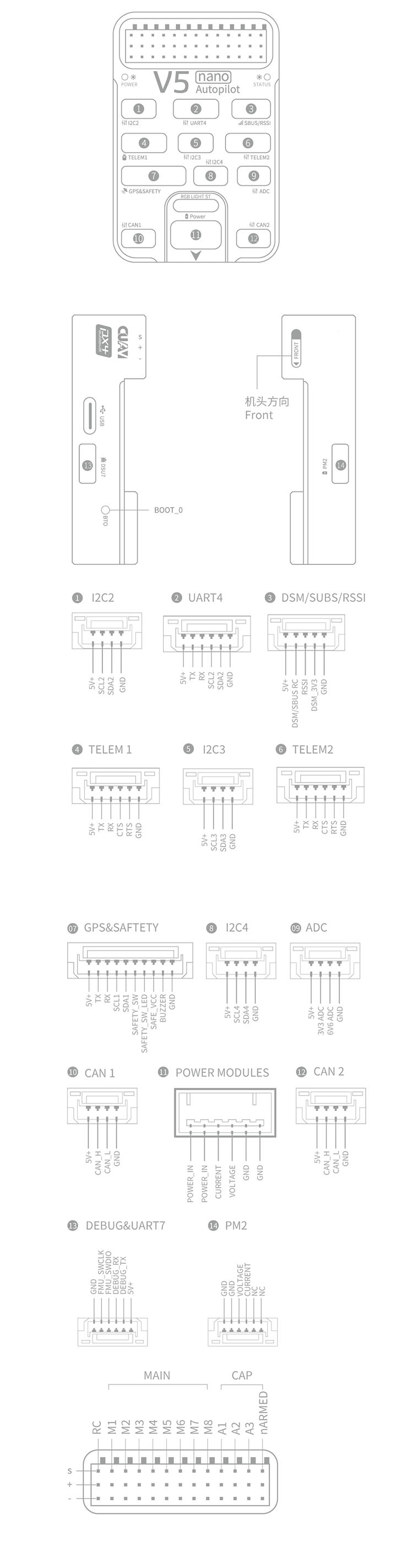

CUAV V5 nano Wiring Quick Start

:::warning PX4 does not manufacture this (or any) autopilot. Contact the manufacturer for hardware support or compliance issues. :::

This quick start guide shows how to power the CUAV V5 nano flight controller and connect its most important peripherals.

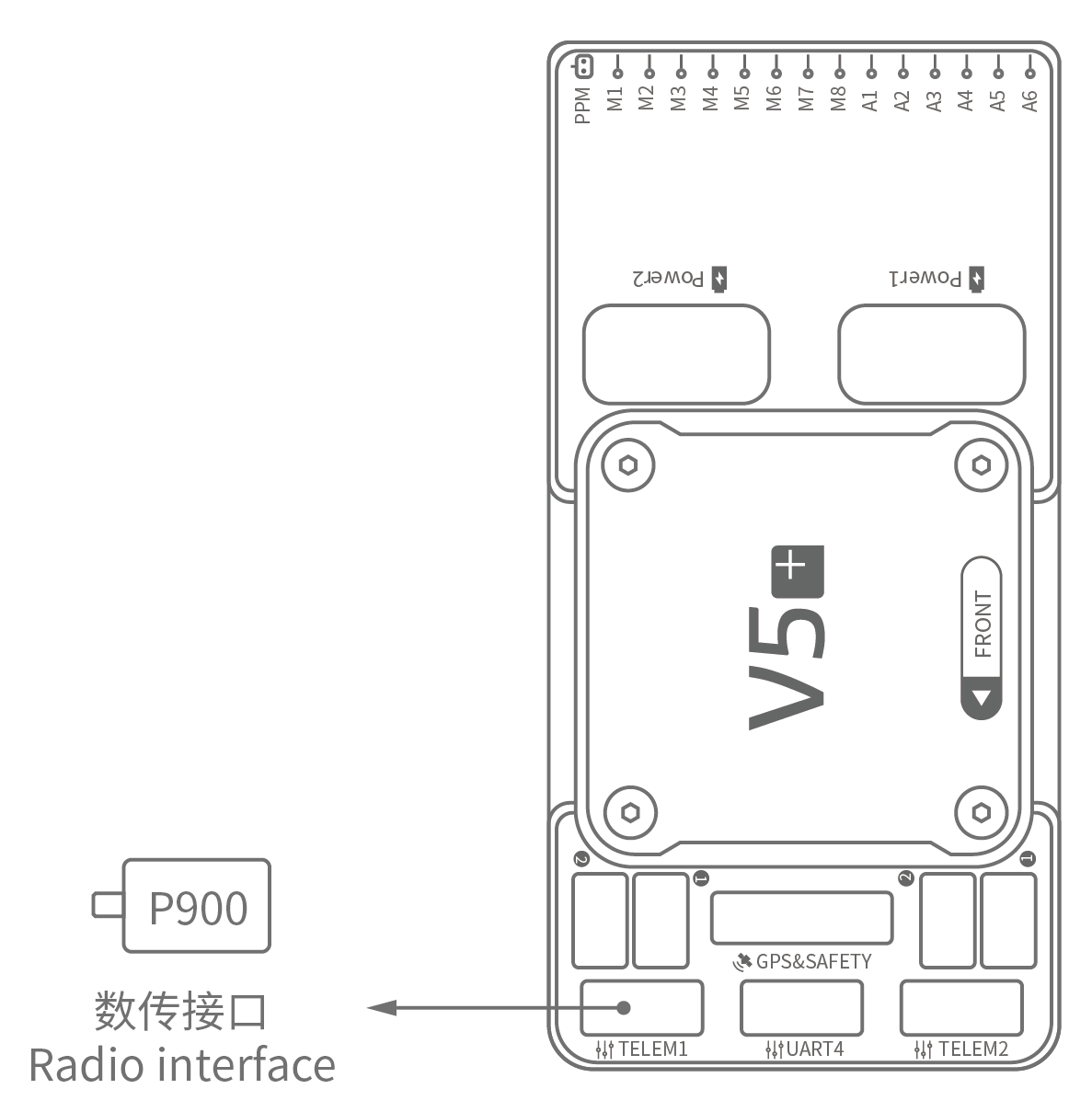

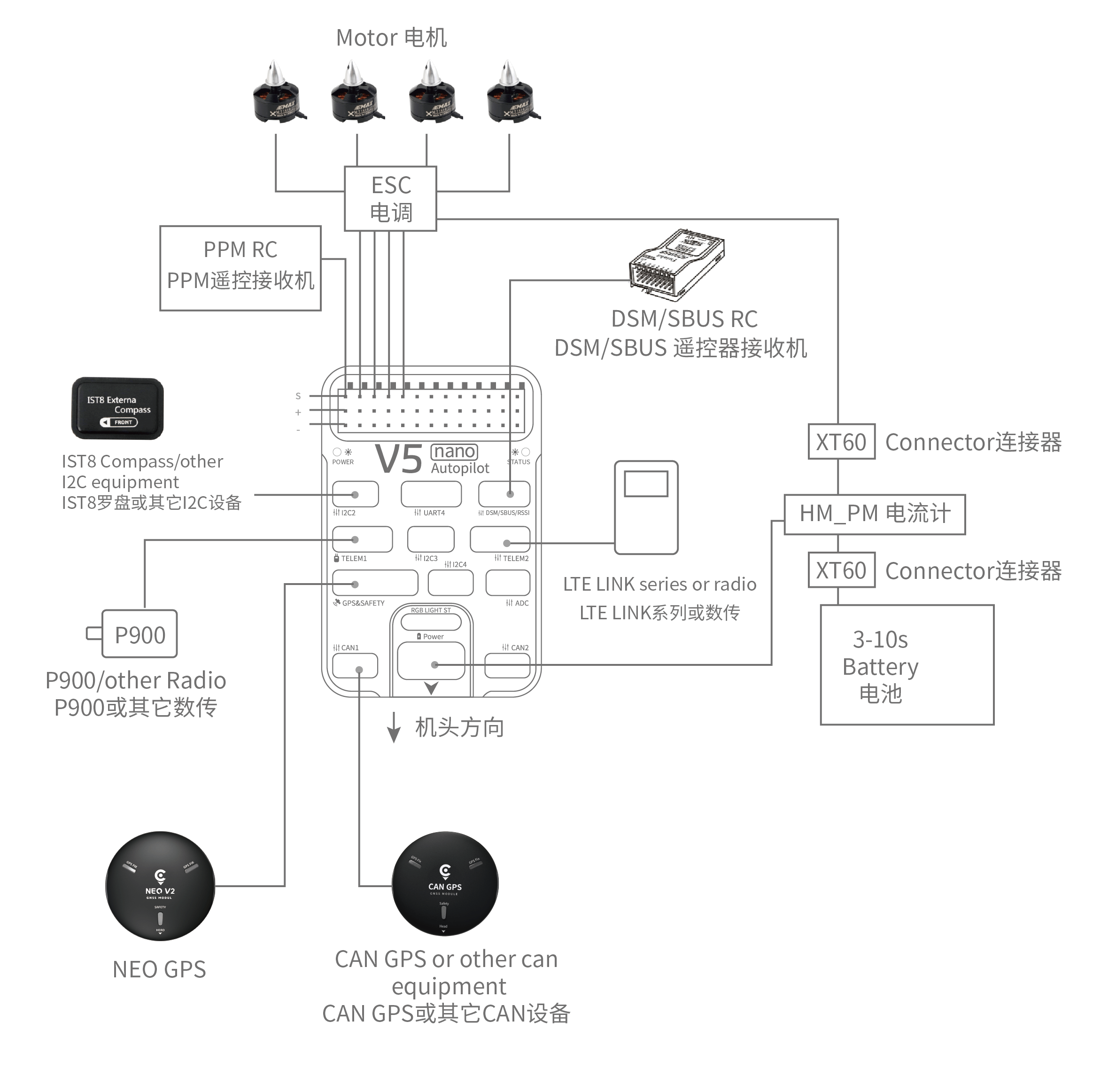

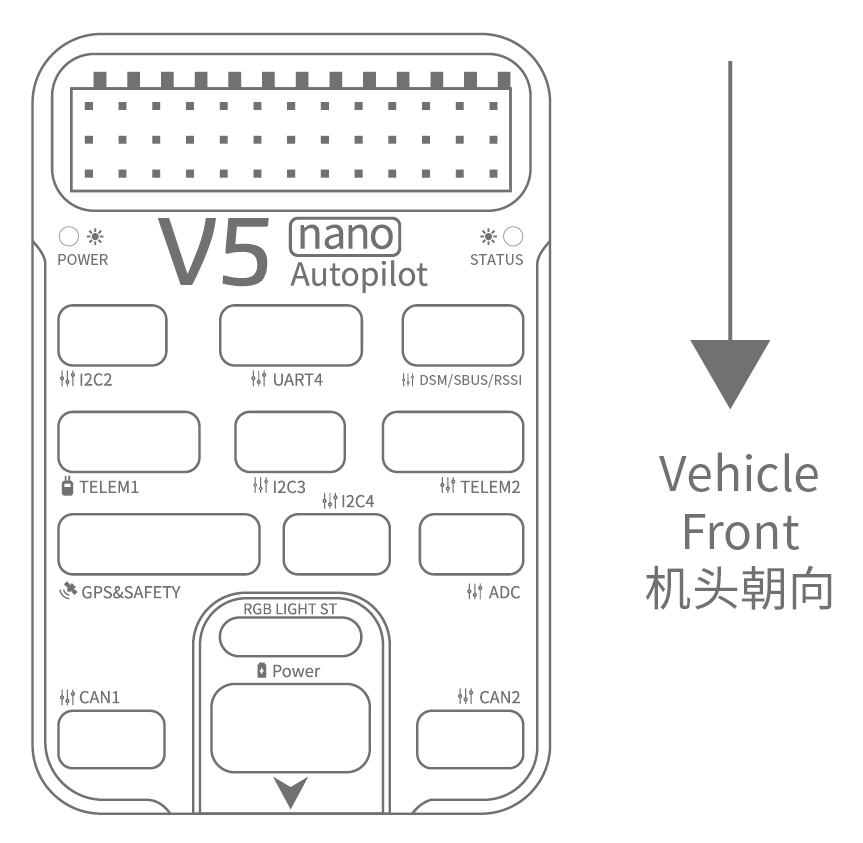

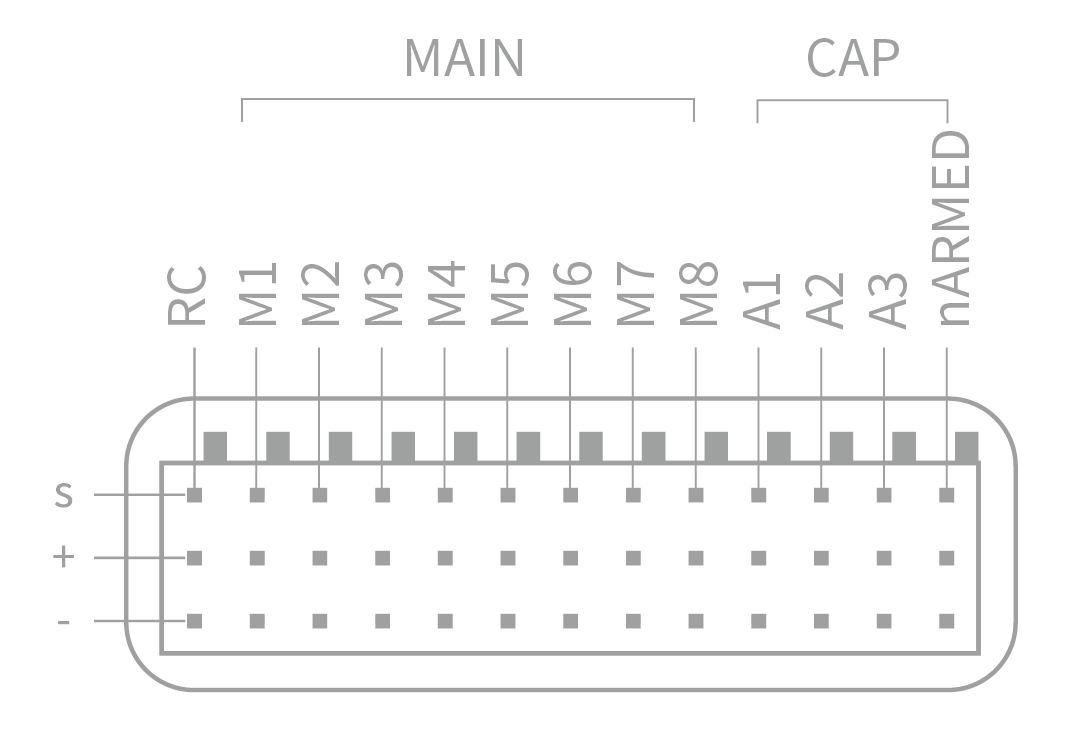

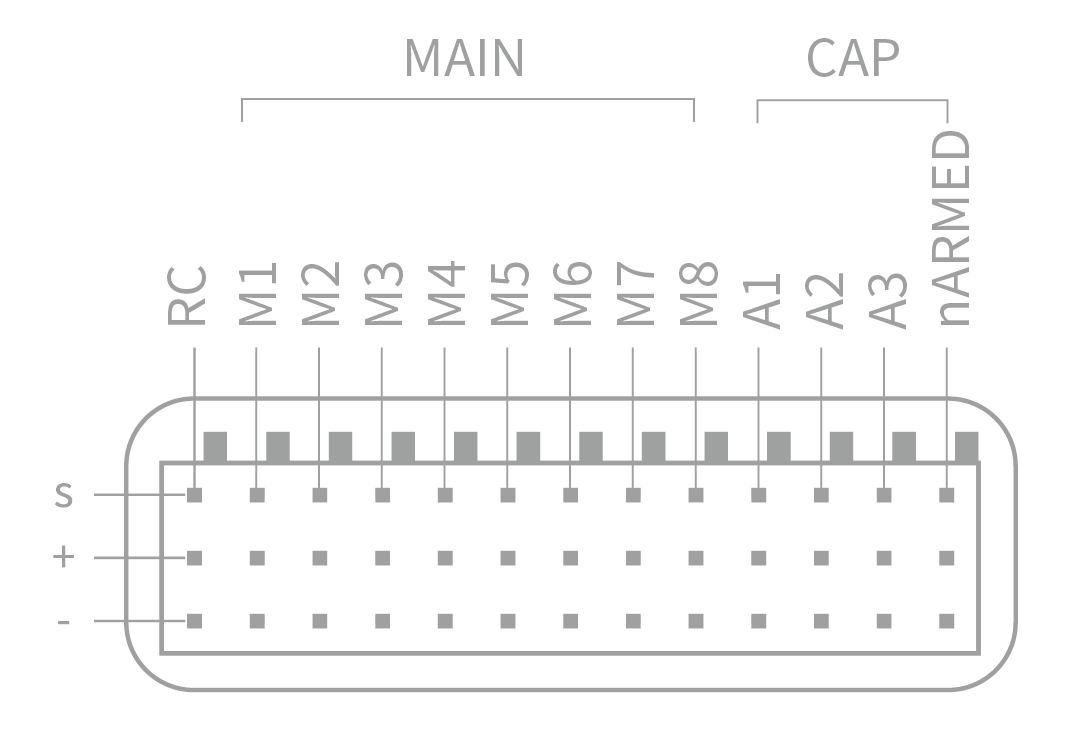

Wiring Chart Overview

The image below shows how to connect the most important sensors and peripherals (except the motor and servo outputs). We’ll go through each of these in detail in the following sections.

| Main interface | Function |

|---|---|

| Power | Connect Power module; Provides Power and ANALOG voltage and current measurements. |

| PM2 | Do not use with PX4 |

| TF CARD | SD card for log storage (comes with card) |

| M1~M8 | PWM outputs. Can be used to control motors or servos. |

| A1~A3 | Capture pins (not currently supported on PX4). |

| nARMED | Indicates the FMU armed state. It is active low (low when armed). |

| DSU7 | Used for FMU debug, reading debug information. |

| I2C2/I2C3/I2C4 | Connect an I2C device such as an external compass. |

| CAN1/CAN2 | Connect UAVCAN devices such as CAN GPS. |

| TYPE-C(USB) | Connect to a computer for communication between the flight controller and the computer, such as loading firmware |

| GPS&SAFETY | Connect to Neo GPS, which includes GPS, safety switch, buzzer interface. |

| TELEM1/TELEM2 | Connect to the Telemetry System. |

| DSM/SBUS/RSSI | Includes DSM, SBUS, RSSI signal input interface, DSM interface can be connected to DSM satellite receiver, SBUS interface to SBUS remote control receiver, RSSI for signal strength return module. |

:::note For more interface information, please read V5 nano Manual. :::

:::note If the controller cannot be mounted in the recommended/default orientation (e.g. due to space constraints) you will need to configure the autopilot software with the orientation that you actually used: Flight Controller Orientation. :::

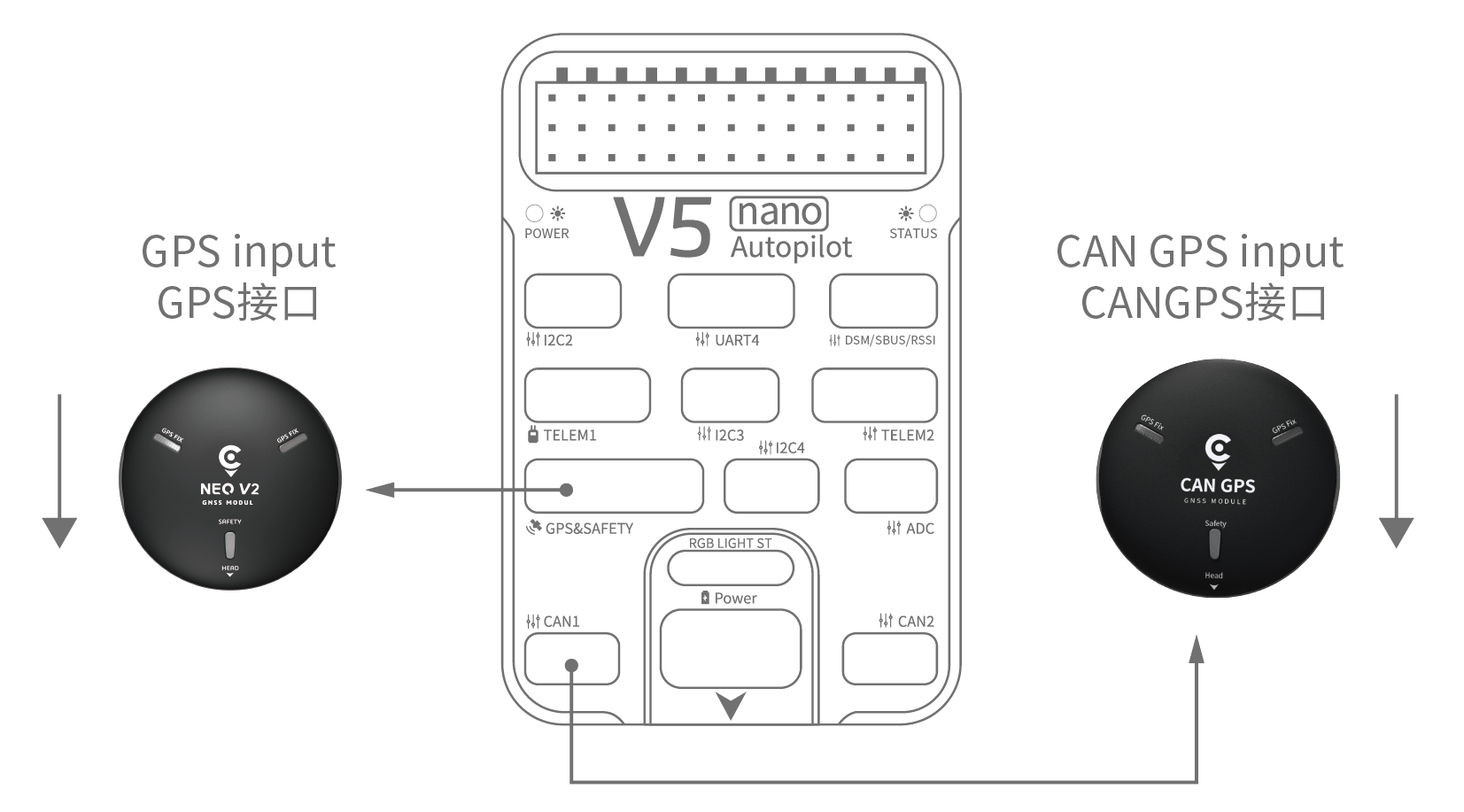

GPS + Compass + Safety Switch + LED

The recommended GPS module is the Neo v2 GPS, which contains GPS, compass, safety switch, buzzer, LED status light.

:::note Other GPS modules may not work (see this compatibility issue). :::

The GPS/Compass module should be mounted on the frame as far away from other electronics as possible, with the direction marker towards the front of the vehicle (Neo GPS arrow is in the same direction as the flight control arrow). Connect to the flight control GPS interface using a cable.

:::note If you use CAN GPS, please use the cable to connect to the flight control CAN interface. :::

Safety Switch

The dedicated safety switch that comes with the V5+ is only required if you are not using the recommended Neo v2 GPS (which has an inbuilt safety switch).

If you are flying without the GPS you must attach the switch directly to the GPS1 port in order to be able to arm the vehicle and fly (If you use the old 6-pin GPS, please read the definition of the bottom interface to change the line).

Buzzer

If you do not use the recommended Neo v2 GPS the buzzer may not work.

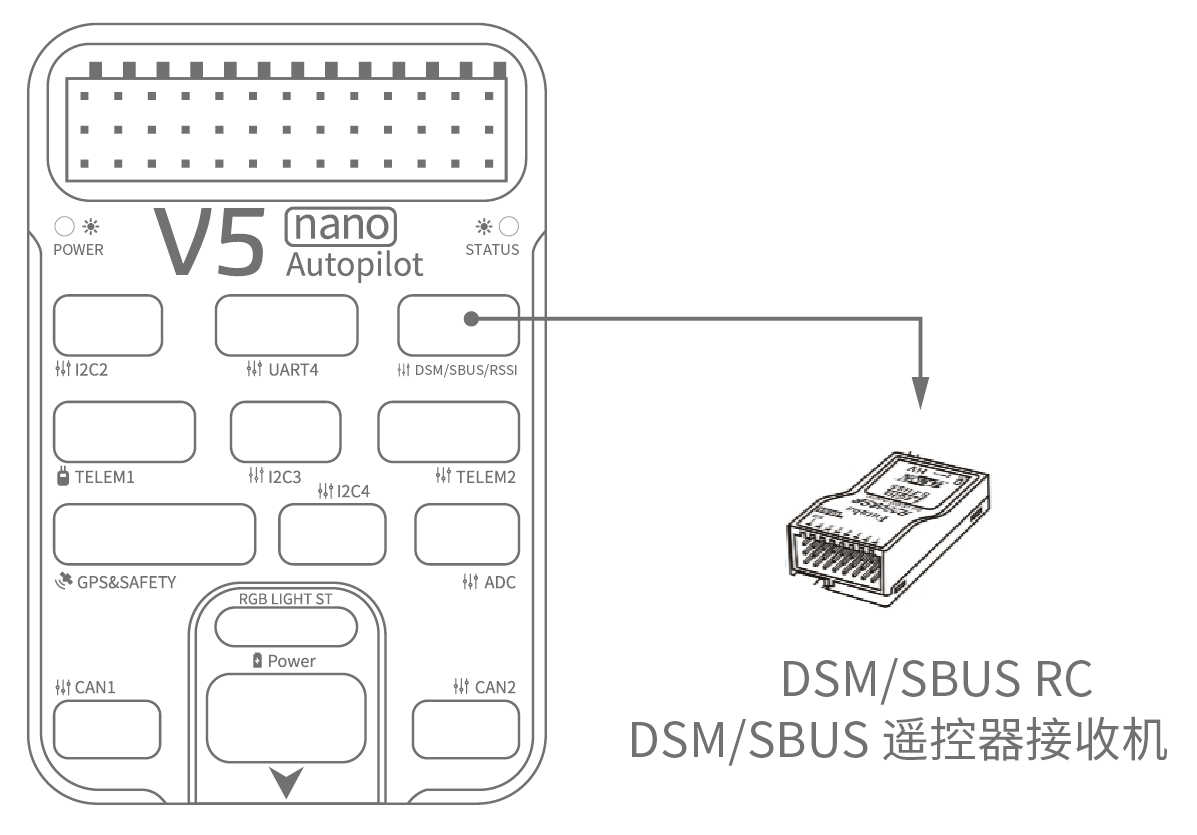

Radio Control

A remote control (RC) radio system is required if you want to manually control your vehicle (PX4 does not require a radio system for autonomous flight modes). You will need to select a compatible transmitter/receiver and then bind them so that they communicate (read the instructions that come with your specific transmitter/receiver).

The figure below shows how you can access your remote receiver (please find the S.Bus cable in the kit)

Spektrum Satellite Receivers

The V5 nano has a dedicated DSM cable.

If using a Spektrum satellite receiver, this should be connected to the flight controller DSM/SBUS/RSSI interface.

Power

The v5 nano kit includes the HV_PM module, which supports 2~14S LiPo batteries.

Connect the 6pin connector of the HW_PM module to the flight control Power interface.

:::warning The supplied power module is unfused. Power must be turned off while connecting peripherals. :::

:::note The power module is not a power source for peripherals connected to the PWM outputs. If you’re connecting servos/actuators you will need to separately power them using a BEC. :::

Telemetry System (Optional)

A telemetry system allows you to communicate with, monitor, and control a vehicle in flight from a ground station (for example, you can direct the UAV to a particular position, or upload a new mission).

The communication channel is via Telemetry Radios. The vehicle-based radio should be connected to the TELEM1 or TELEM2 port (if connected to these ports, no further configuration is required). The other radio is connected to your ground station computer or mobile device (usually via USB).

SD Card (Optional)

An SD card is inserted in the factory (you do not need to do anything).

Motors

Motors/servos are connected to the MAIN ports in the order specified for your vehicle in the Airframes Reference.

Pinouts

Further Information

- Airframe buildlog using CUAV v5 nano on a DJI FlameWheel450

- CUAV V5 nano

- V5 nano manual (CUAV)

- FMUv5 reference design pinout (CUAV)

- CUAV Github (CUAV)

mount and orient controller - APM, Mission-planner

Mounting the Flight Controller

Orientation

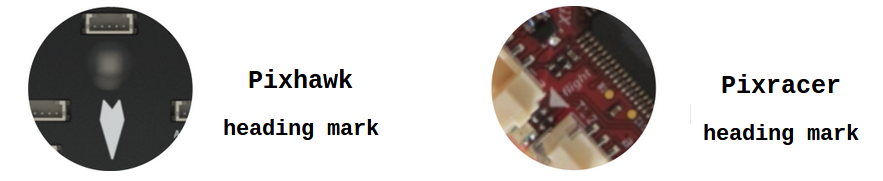

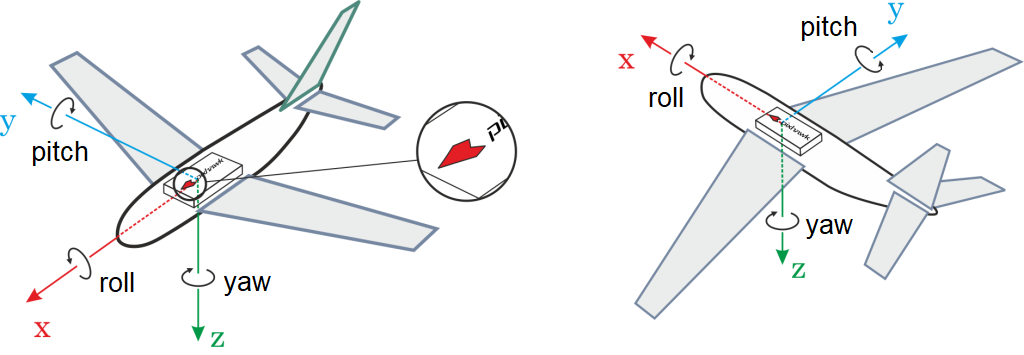

Almost all Flight Controllers have a heading mark arrow (shown below). The controller should be placed on the frame top-side up, oriented so that the arrow points towards the front of the vehicle (on all aircraft frames - airplane, multirotor, VTOL, ground vehicles etc.).

:::note If the controller cannot be mounted in the recommended/default orientation (e.g. due to physical constraints) you will need to configure the autopilot software with the orientation that you actually used: Flight Controller Orientation. :::

Vibration Isolation

Flight Control boards with in-built accelerometers or gyros are sensitive to vibrations. Some boards include in-built vibration-isolation, while others come with mounting foam that you can use to isolate the controller from the vehicle.

Vibration damping foam

Vibration damping foam

You should use the mounting strategy recommended in your flight controller documentation.

:::tip Log Analysis using Flight Review > Vibration explains how to test whether vibration levels are acceptable, and Vibration Isolation suggests a number of possible solutions if there is a problem. :::

- APM, Mission-planner

Basic Assembly

A typical autopilot “minimal” system running PX4 consists of a flight controller connected to a power system, GPS, external compass (optional), radio control system (optional) and/or telemetry radio system (optional).

This section contains topics that explain how to assemble such a system for different flight controllers.

:::tip Quickstart guides are only provided for a few controllers. Other controllers will have similar connections. Additional information may be available in flight controllers pages or in manufacturer documentation. :::

- See Peripherals for information about connecting sensors and other peripherals (e.g. airspeed sensor for planes).

- See Airframe Builds for complete assembly examples on different vehicle frames.

- See Multicopter Racer Setup for racer-specific assembly and configuration information.

airframe reference - APM, Mission-planner

Airframes Reference

:::note

This list is auto-generated from the source code using the build command: make airframe_metadata.

:::

This page lists all supported airframes and types including the motor assignment and numbering. The motors in green rotate clockwise, the ones in blue counterclockwise.

AUX channels may not be present on some flight controllers. If present, PWM AUX channels are commonly labelled AUX OUT.

Airship

Airship

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Cloudship | Maintainer: John Doe <john@example.com>

|

Autogyro

Autogyro

| Common Outputs |

|---|

|

| Name | |

|---|---|

| ThunderFly Auto-G2 | Maintainer: ThunderFly s.r.o., Roman Dvorak <dvorakroman@thunderfly.cz>

Specific Outputs:

|

| ThunderFly TF-G2 | Maintainer: ThunderFly s.r.o., Roman Dvorak <dvorakroman@thunderfly.cz>

Specific Outputs:

|

Balloon

Balloon

| Name | |

|---|---|

| ThunderFly balloon TF-B1 | Maintainer: ThunderFly s.r.o.

|

Copter

Coaxial Helicopter

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Esky (Big) Lama v4 | Maintainer: Emmanuel Roussel

|

Dodecarotor cox

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Generic Dodecarotor cox geometry | Maintainer: William Peale <develop707@gmail.com>

|

Helicopter

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Blade 130X | Maintainer: Bart Slinger <bartslinger@gmail.com>

|

Hexarotor +

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Generic Hexarotor + geometry | Maintainer: Lorenz Meier <lorenz@px4.io>

|

Hexarotor Coaxial

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Generic Hexarotor coaxial geometry | Maintainer: Lorenz Meier <lorenz@px4.io>

|

Hexarotor x

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Generic Hexarotor x geometry | Maintainer: Lorenz Meier <lorenz@px4.io>

Specific Outputs:

|

| UVify Draco-R | Maintainer: Hyon Lim <lim@uvify.com>

Specific Outputs:

|

| Hex X with control allocation | Maintainer: Silvan Fuhrer

|

Octo Coax Wide

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Steadidrone MAVRIK | Maintainer: Simon Wilks <simon@uaventure.com>

|

Octorotor +

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Generic Octocopter + geometry | Maintainer: Lorenz Meier <lorenz@px4.io>

|

Octorotor Coaxial

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Generic 10" Octo coaxial geometry | Maintainer: Lorenz Meier <lorenz@px4.io>

|

Octorotor x

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Generic Octocopter X geometry | Maintainer: Lorenz Meier <lorenz@px4.io>

|

Quadrotor +

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Generic 10" Quad + geometry | Maintainer: Lorenz Meier <lorenz@px4.io>

|

Quadrotor H

| Name | |

|---|---|

| Reaper 500 Quad | Maintainer: Blankered

Specific Outputs:

|

| BetaFPV Beta75X 2S Brushless Whoop | Maintainer: Beat Kueng <beat-kueng@gmx.net>

Specific Outputs:

|

Quadrotor Wide

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Team Blacksheep Discovery | Maintainer: Lorenz Meier <lorenz@px4.io>

Specific Outputs:

|

| 3DR Iris Quadrotor | Maintainer: Lorenz Meier <lorenz@px4.io>

Specific Outputs:

|

| Steadidrone QU4D | Maintainer: Lorenz Meier <lorenz@px4.io>

Specific Outputs:

|

| Team Blacksheep Discovery Endurance | Maintainer: Simon Wilks <simon@uaventure.com>

Specific Outputs:

|

Quadrotor asymmetric

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Spedix S250AQ | Maintainer: Lorenz Meier <lorenz@px4.io>

|

Quadrotor x

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Generic Quadcopter | Maintainer: Lorenz Meier <lorenz@px4.io>

Specific Outputs:

|

| Lumenier QAV-R (raceblade) 5" arms | Maintainer: James Goppert <james.goppert@gmail.com>

|

| Lumenier QAV250 | Maintainer: Lorenz Meier <lorenz@px4.io>

|

| DJI F330 w/ DJI ESCs | Maintainer: Lorenz Meier <lorenz@px4.io>

|

| DJI F450 w/ DJI ESCs | Maintainer: Lorenz Meier <lorenz@px4.io>

|

| S500 Generic | Maintainer: Lorenz Meier <lorenz@px4.io>

|

| Holybro S500 | Maintainer: Lorenz Meier <lorenz@px4.io>

|

| PX4 Vision DevKit Platform | Maintainer: John Doe <john@example.com>

Specific Outputs:

|

| NXP HoverGames | Maintainer: Iain Galloway <iain.galloway@nxp.com>

Specific Outputs:

|

| S500 with control allocation | Maintainer: Silvan Fuhrer

|

| 3DR Solo | Maintainer: Andreas Antener <andreas@uaventure.com>

|

| 3DR DIY Quad | Maintainer: Lorenz Meier <lorenz@px4.io>

|

| Generic 250 Racer | Maintainer: Lorenz Meier <lorenz@px4.io>

|

| HolyBro QAV250 | Maintainer: Beat Kueng <beat-kueng@gmx.net>

|

| Holybro Kopis 2 | Maintainer: Beat Kueng <beat@px4.io>

|

| DJI Matrice 100 | Maintainer: James Goppert <james.goppert@gmail.com>

|

| Advanced Technology Labs (ATL) Mantis EDU |

Specific Outputs:

|

| UVify IFO | Maintainer: Hyon Lim <lim@uvify.com>

Specific Outputs:

|

| UVify Draco | Maintainer: Hyon Lim <lim@uvify.com>

Specific Outputs:

|

| UVify IFO | Maintainer: Hyon Lim <lim@uvify.com>

Specific Outputs:

|

| ZMR250 Racer | Maintainer: Anton Matosov <anton.matosov@gmail.com>

|

| NanoMind 110 Quad | Maintainer: Henry Zhang <zhanghui629@gmail.com>

|

| Teal One | Maintainer: Matt McFadden <matt.mcfadden@tealdrones.com>

Specific Outputs:

|

| COEX Clover 4 | Maintainer: Oleg Kalachev <okalachev@gmail.com>

|

| Crazyflie 2 | Maintainer: Dennis Shtatov <densht@gmail.com>

|

| Crazyflie 2.1 | Maintainer: Dennis Shtatov <densht@gmail.com>

|

Simulation (Copter)

| Name | |

|---|---|

| HIL Quadcopter X | Maintainer: Lorenz Meier <lorenz@px4.io>

|

| SIH Quadcopter X | Maintainer: Romain Chiappinelli <romain.chiap@gmail.com>

|

Tilt-Quad

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Tilt-Quadrotor | Maintainer: Ricardo Marques <marques.ricardo17@gmail.com>

|

Tricopter Y+

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Generic Tricopter Y+ Geometry | Maintainer: Trent Lukaczyk <aerialhedgehog@gmail.com>

|

Tricopter Y-

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Generic Tricopter Y- Geometry | Maintainer: Trent Lukaczyk <aerialhedgehog@gmail.com>

|

Plane

Flying Wing

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Generic Flying Wing |

Specific Outputs:

|

| IO Camflyer | Maintainer: Simon Wilks <simon@uaventure.com>

Specific Outputs:

|

| Phantom FPV Flying Wing | Maintainer: Simon Wilks <simon@uaventure.com>

Specific Outputs:

|

| Skywalker X5 Flying Wing | Maintainer: Julian Oes <julian@px4.io>

Specific Outputs:

|

| Wing Wing (aka Z-84) Flying Wing | Maintainer: Lorenz Meier <lorenz@px4.io>

Specific Outputs:

|

| FX-79 Buffalo Flying Wing | Maintainer: Simon Wilks <simon@uaventure.com>

Specific Outputs:

|

| Viper | Maintainer: Simon Wilks <simon@uaventure.com>

Specific Outputs:

|

| Sparkle Tech Pigeon | Maintainer: Simon Wilks <simon@uaventure.com>

Specific Outputs:

|

| Modified Parrot Disco | Maintainer: Jan Liphardt <JTLiphardt@gmail.com>

Specific Outputs:

|

| TBS Caipirinha | Maintainer: Lorenz Meier <lorenz@px4.io>

Specific Outputs:

|

Plane A-Tail

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Applied Aeronautics Albatross | Maintainer: Andreas Antener <andreas@uaventure.com>

|

Plane V-Tail

| Common Outputs |

|---|

|

| Name | |

|---|---|

| X-UAV Mini Talon | Maintainer: Friedrich Beckmann <friedrich.beckmann@hs-augsburg.de>

|

Simulation (Plane)

| Common Outputs |

|---|

|

| Name | |

|---|---|

| HILStar (XPlane) | Maintainer: Lorenz Meier <lorenz@px4.io>

|

| SIH plane AERT | Maintainer: Romain Chiappinelli <romain.chiap@gmail.com>

|

Standard Plane

| Common Outputs |

|---|

|

| Name | |

|---|---|

| Standard Plane | Maintainer: Lorenz Meier <lorenz@px4.io>

Specific Outputs:

|

| Bormatec Maja | Maintainer: Andreas Antener <andreas@uaventure.com>

Specific Outputs:

|

Rover

Rover

| Name | |

|---|---|

| Generic Ground Vehicle |

Specific Outputs:

|

| Aion Robotics R1 UGV | Maintainer: Timothy Scott

Specific Outputs:

|

| NXP Cup car: DF Robot GPX | Maintainer: Katrin Moritz

Specific Outputs:

|

Underwater Robot

Underwater Robot

| Name | |

|---|---|

| Generic Underwater Robot |

|

| HippoCampus UUV (Unmanned Underwater Vehicle) | Maintainer: Daniel Duecker <daniel.duecker@tuhh.de>

|

Vectored 6 DOF UUV

| Common Outputs |

|---|

|

| Name | |